Massachusetts Institute of Technology (MIT) scientists have announced what they claim is a “Significant advance in battery architecture [that] could be breakthrough for electric vehicles and grid storage.”

According to a story by David L. Chandler from the MIT News Office, the new battery system is lightweight and inexpensive, and could make recharging “as quick and easy as pumping gas into a conventional car.”

Seemingly requiring some active components within the battery, this “semi-solid flow cell” pumps solid particles suspended in a carrier liquid which form the cathodes and anodes through the system. According to the MIT news item, “These two different suspensions are pumped through systems separated by a filter, such as a thin porous membrane.” Mechanically more complex than today’s batteries, the system still has a claimed “10-fold improvement over present liquid-flow batteries” (not necessarily that much better than lithium ion, then), but lower manufacturing costs.

The different fluids are contained in two different containers and not brought together until energy is needed. A user would always have a “fresh” battery with this system, unlike conventional cells that lose energy over time because all the ingredients are contained in a single structure and interact to varying degrees. The team also claims that the system will be smaller and less expensive than extant batteries, perhaps, “about half the current levels.” They think this could “be the key to making electric vehicles fully competitive with conventional gas- or diesel-powered vehicles”

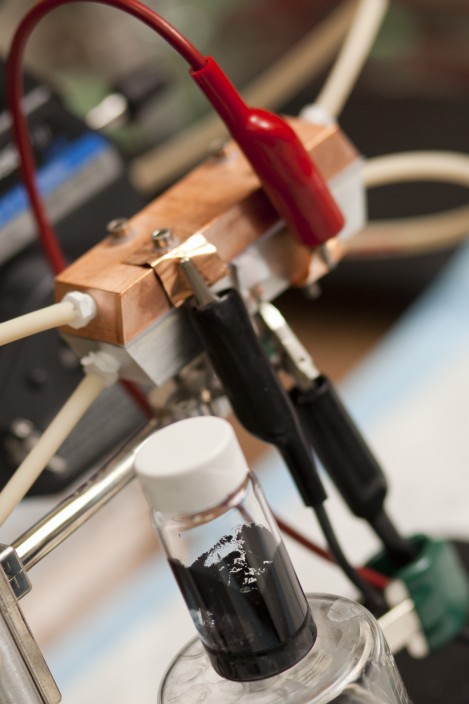

The high energy density fluids are dark and “gooey,” leading to their nickname, “Cambridge crude.” Researcher Yet-Ming Chiang told Discovery.com that, “”It’s a flowing electrode that’s electrically conductive all of the time. That’s the secret sauce.”

Chandler’s story goes on, “The work was carried out by Mihai Duduta ’10 and graduate student Bryan Ho, under the leadership of professors of materials science W. Craig Carter and Yet-Ming Chiang. It is described in a paper published May 20 in the journal Advanced Energy Materials. The paper was co-authored by visiting research scientist Pimpa Limthongkul ’02, postdoc Vanessa Wood ’10 and graduate student Victor Brunini ’08.”

Combining the separate storage of quicksand-like fluids with “the proven chemistry of lithium-ion batteries” led to the potential for new developments. Researchers claim the system could be increased in size for energy storage for wind and solar projects.

Schematic of MIT battery, with anode and cathode materials separated until being combined in central "reactor"

Chiang was involved in the 2001 startup of A123 Systems, whose batteries power a vast number of portable electric tools. In contrast, the fluid-flow battery system will not be a good candidate for such small, high-power uses, but will be better used as a source for long-range, long-term vehicle or utility applications.

“The new technology is being licensed to a company called 24M Technologies,” according to the press release, has raised “more than $16 million in venture capital” and received grants from the Defense Advanced Research Projects Agency (DARPA) and Advance Research Projects Agency – Energy (ARPA-E).

Professors Angela Belcher and Paula Hammond at MIT and Glenn Amatucci at Rutgers are adding their research acumen to the project, with the goal of producing a prototype “ready to be engineered for production as a replacement for existing car batteries.”

Best of all, according to Discovery.com, “The electro-chemical fuel can be reused so drivers could feasibly swap out a spent tank of for one that’s been charged. Since the batteries decouple energy and power, fueling stations could offer different types of electro-chemical fuel.

“’If you would like high-power fuel, we could give you high-power fuel. If you would like longer-range fuel: ‘premium range,’ Chiang said. This would give drivers the ability to get electro-chemical fuel tailored to their operating conditions — as well as the season. Electrolyte chemists usually design for the broadest range of temperatures, giving up performance at the high and low ends.

“’The sweet spot we’re aiming for is a battery with enough power for any vehicle application but with the longest run-time possible,’ Chiang said.

“’People talk about ‘range anxiety,’ Chiang said. ‘Our goal is to provide ‘range euphoria.'”

Comments 1

MCR4s won Green Flight Challenge 11 years ago!!

Check the specs of MCR4s here: http://www.love4aviation.com/Aircraft/MCR-4S+index/Specifications.html

Total passenger: 4

Standard tank size: 34.4 gallons

Now look at the GFC criteria and check for yourself!!!

(Editor’s note: Rahul has posted the following on the Homebuilt Aircraft Forum:

“Cafe rejected my comment on MCR4s!

“Okay, so they didnt even allow me to post this on their website

“If this is open to all with nothing but facts, why not allow people to see where you failed!

“They will know it eventually and besides the synergy everything else is never going to make it to GA anyways!!”

I have emailed Rahul to let him know that his comment gave me an idea for a blog entry that will begin with his comment. I’ve made the same point in last year’s presentation at the Electric Aircraft Symposium. Mike Arnold’s AR5, for instance, if throttled back to 100 mph, could make GFC mileage – even with a two-stroke. Dieselis or Gazaille approach GFC criteria with their Diesel engines. I would tend to agree with Rahul’s numbers rather than attempt to supress them. Look for the entry in the next few weeks. I spend a great deal of time researching and interviewing people for these entries, so timelines vary.)

I’m posting the comment now to halt any intimation that CAFE, or I acting as writer and editor of their blog, are censoring anyone. This is a wide-open forum, and the only things I reject are comments that have commercial links not related to the subject at hand, or personal attacks on subjects of entries or other commenters. I like the Homebuilt Aircraft Forum and think it’s the lively kind of discussion I’d like to see here. Feel free to jump in here.)

——————–GFC———–MCR- 65% power——-MCR- 53% power

Speed(mph)———100————–158———————147*

distance(miles)——200————-1146——————–2528

Fuel consp.(gph)—–na—————4.7———————2(based on Rotax website**)

Fuel eff(pass-mile)—200————-134———————294

* speed at 53hp = 158*(53/65)^1/3= 147 mph (assuming 158mph @65hp)

** @2gph Rotax 912 ULS/s makes 40KW = 53hp: http://www.rotax-aircraft-engines.com/portaldata/5/data/perf912uls.pdf

The MCR4-s not only hits every single one of the GFC specs, but hits them in style!!

Besides this being from Europe( but so is pipistrel and PCaero and all you had to do was collaborate with someone in US ) what is it that this is missing from the specs!