Bio-mimicry presents itself in aerodynamics, from the emulation of soaring bird’s wing shapes on sailplane’s surfaces to owl-feather-like trailing edges on wind turbines. We don’t often think of biological equivalents in energy storage (your editor didn’t until now, at least). But researchers at Cambridge University in England and the Beijing Institute of Technology in China have turned to the small intestine for their breakthrough in battery development. Tiny cells lining the human intestine inspired these researchers to develop a prototype of a lithium-sulfur battery that they claim could have five times the energy density of conventional lithium-ion batteries. Dr. Paul Coxon from Cambridge’s Department of Materials Science and Metallurgy says “This gets us a long way through the bottleneck which is preventing the development of better batteries.” Is That You, Villi? Villi in the gut help process food being digested, trapping nutrient particles in millions of tiny, “finger-like protrusions” which increase the absorbent surface area over which digestion takes place. …

Making Silicon Anodes in Large Batches

A Long-term Collaboration Dr. Jaephil Cho is a well-known battery researcher and inter-continental associate of Dr. Yi Cui of Stanford University. The pair has collaborated on many ways to improve battery performance and longevity, and both have appeared at various electric aircraft symposia. They have even inspired others in related research. Dr. Cho and his team at Ulsan National Institute of Science and Technology (UNIST) in South Korea announced a way to make a new generation battery anode material – a big move toward mass production of improved cells. Dr. Cho’s team of researchers affiliated with Ulsan National Institute of Science and Technology (UNIST), South Korea, claims to have made yet another step towards finding a solution to accelerate the commercialization of silicon anodes for Lithium-ion batteries. A Next-generation Hybrid Anode As reported by UNIST, “Prof. Cho and his research team have developed a new type anode material that would be used in place of a conventional graphite anode, which they …

Getting Blood from Outback Joe – the 2016 Outback Challenge

Outback Joe goes through a lot of trauma in his overstuffed life. This literal straw man gets tossed into some remote part of the Australian outback every year and waits for some kind of rescue. This usually comes by air, drones searching for him and taking him medicine, food, water, or some other necessity. That’s the Outback Challenge. One can see a condensed history of the competition from its inception in 2007 to today on Wikipedia, the entry including the different kinds of things Outback Joe needed for a mission to be successful. This year, however, competitors were supposed to bring back a reminder of their visit to Joe – a blood sample – a good trick from an inanimate being who might answer to “Hay!” Richard Glassock, now a Research Fellow at the Institute for Aerospace Technology, the University of Nottingham, describes the vision and how it has grown up. “The competition Rod Walker and I first discussed about …

Graphene Supercapacitor Shows Promise and Longevity

A forever battery would be nice, wouldn’t it? Something low cost that could be recharged in seconds, time after time, indefinitely, and be about as environmentally sensitive as Greenpeace and the Sierra Club combined – there’s the ideal battery. That might seem like a miracle, and it relies on that miracle material – graphene – for its many astounding properties to help make this flexible battery a reality. Dr. Han Lin of Swinburne University in New South Wales, Australia has 3D printed his prototype battery at a much lower cost than with previous production techniques. The immediate “take” on this material is that it could be used in things like watch straps, powering the attached timekeeper, or in (inter)active sports clothing. Of course, this blog looks for larger applications, such as something that could be used in electric aircraft. Graphene has the potential to be a structural material (about a hundred times stronger than steel, according to 3ders.org) and a …

Toyota Explores the Magnesium Alternative

We’d all love an electric car (or an airplane) that goes more than 100 miles flashing a “Low Battery” indicator. Researchers at the Toyota Research Institute of North America (TRINA) are working on a divergent approach to achieving greater range and smaller battery sizes by using magnesium as an active ingredient. In a bit of serendipitous synergy, Toyota principal scientist and chemical engineer Rana Mahtadi heard fellow researchers discussing development of an electrolyte for a practical magnesium battery. She was researching hydrogen storage materials and their application to fuel cell technology at the time, and realized the two lines of research intersected nicely. Toyota explains that “Magnesium metal has long been theorized as a much safer and more energy-dense alternative to current lithium battery technology. Lithium metal, in its natural state, is unstable and can ignite when exposed to air. In order to make lithium metal safe for batteries, ions are taken from the lithium metal and embedded into graphite …

Silicon, Sulfur and 3D graphene Makes High-Performance Battery

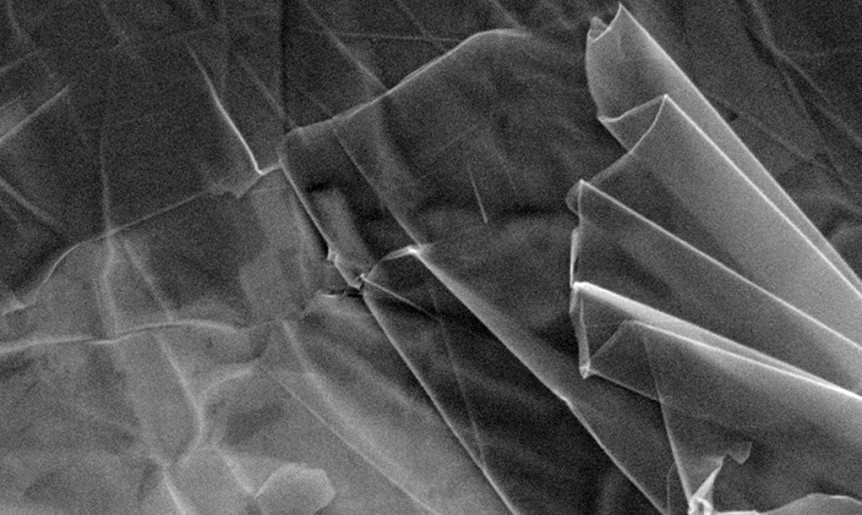

Lithium-sulfur batteries display winning qualities, such as low production cost, environmental friendliness, and high energy density. Researchers usually give up, or look elsewhere, when the materials’ poor cycle life and loss of active materials on both anode and cathode show up. Researchers at Beihang University in Beijing report developing “a new Li-sulfur battery using honeycomb-like sulfur copolymer uniformly distributed onto 3D graphene (3D cpS-G) networks for a cathode material and a 3D lithiated Si-G network as anode.” They report “a high reversible capacity of 620 milli-Amp hours per gram, [and an] ultrahigh energy density of 1,147 Watt-hours per kilogram (based on the total mass of cathode and anode), good high-rate capability and excellent cycle performance over 500 cycles (0.028% capacity loss per cycle).” The materials used in the cathode and anode presented challenges. The “inherent insulation of sulfur” on the cathode and the high solubility of polysulfide intermediates cause an inability of the active materials to respond to one another, …

NASA Rethinks X Planes

In your editor’s childhood and youth, X Planes were all premised on speed, Chuck Yeager breaking the sound barrier in 1947 in the Bell X-1 when your editor was five years old (do the math). Movies that filled screens in those days featured test pilots as steely-jawed, fearless protagonists beating back the awesome forces in the sky. Frequent news stories and breathlessly narrated newsreels, and later television news captured the imagination with items about going higher, faster, and farther. NASA is bringing back the X-plane, but emphasizing quiet, efficient, clean and practical goals. NASA’s own description of the programs shows a turn toward green aviation in our future. “Goals include showcasing how airliners can burn half the fuel and generate 75 percent less pollution during each flight as compared to now, while also being much quieter than today’s jets – perhaps even when flying supersonic.” We still feel the need for speed, but responsibly. While the X-1 was a product …

SULSA Guides the Royal Navy

We reported on the reputedly first 3D-printed airplane, a laser-sintered plastic craft with a structure we compared to that of the WWII Wellington bomber, almost five years ago. Since then, the aircraft has been dubbed SULSA (Southampton University Laser Sintered Airplane) and taken its place with the Royal Navy. Jim Scanlan, lead academic on the project and professor of design within engineering and the environment at the University, explains, “Not all of our aircraft are 3D printed and the biggest one is around 60 per cent 3D printed. At the moment we make this lovely sophisticated lightweight structure and then spend a week making all the wiring and soldering. It’s labor-intensive and error prone. Our vision is that we print all the wiring into the structure at the same time and that will be a huge step forward.” He credits the designer of the Wellington for inspiring the small craft’s internal geodesics. “Barnes Wallis developed a very efficient geodesic structure …

Quart in a Pint Pot

Lilium is still in its incubator stage, but drawing a lot of interest for its radical two-seat, high-speed aerial vehicle. EIT Climate-KIC, one of the funding organizations helping underwrite this startup, includes some startling claims in Lilium’s description. “Lilium is designing the world’s fastest and highest-range electric aircraft that is commercially available. “The two-seated light aircraft consumes half the energy of today’s most efficient electric cars and is so quiet that it can’t be heard flying in 1 km (@3,300 feet) altitude. It is propelled by electric impeller engines and features an extensive safety concept comprising a 3-fold redundant fly-by-wire control system, 12 redundant batteries and engines as well as a parachute rescue system for the whole aircraft.” The ESA Business Incubation Center, another of Lilium’s backers, has more: “Lilium is developing, building, and selling a two-seated electric jet capable of vertical take-off and landing (VTOL). The company was founded in February 2015 by four engineers and Ph.D students from Technische Universität …

Superoxides May Be New Super Materials for Batteries

A significantly large and geographically diverse group of researchers has invested a large amount of time and intellectual capital investigating superoxides, an innovative way to keep lithium-air batteries refreshed and ready for more. Groups at Argonne National Laboratory, the University of Illinois at Chicago, Hanyang University in Seoul, South Korea; the University of Utah and the University of Kentucky all contributed to the ongoing project. While still serving as U. S. Secretary of Energy, Steven Chu called on academia and industry to develop a battery five times as powerful as then available lithium cells, at one-fifth the cost of then current batteries. We may not have arrived at that ambitious goal yet, but Argonne and UIC see a possible breakthrough in making lithium-air batteries – theoretically the most energetic of lithium chemistries – into long-lasting, energy-dense energy storage units. So far, lithium air batteries have a limiting weakness, the use of lithium peroxide, something that ends up being “an insoluble …