Dr. Amy Prieto created her namesake battery a decade ago, and has been seeking funding and other support for its development ever since. It gained such funding from Stanley Ventures in 2016. Prieto Battery, as reported by GreenCarCongress.com then, is, “A company commercializing a 3D Lithium-ion battery technology (earlier post), announced a strategic investment from Stanley Ventures, the venture arm of Stanley Black & Decker, a world-leading provider of tools and storage, commercial electronic security and engineered fastening systems.”

Possibly more important that money, Dr. Prieto’s battery recently received third-party validation of its claimed safety and performance attributes from Energy Assurance, LLC. GreenCarCongress reports, “Specifically, Prieto had a group of fully assembled batteries containing their proprietary 3D anode tested against an array of UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) standards for Li-ion chemistry. All of Prieto’s batteries had 100% success rate with zero failures.”

Dr. Prieto seems happy with these results, stating, “These results validate the science and manufacturing methodology we’ve been working on for a long time. Besides demonstrating that our chemistry and materials are safer, it’s equally as impressive that none of the cells failed and points to an exciting pivot point in our company, one where we move from focusing on R&D to getting our first product commercialized.”

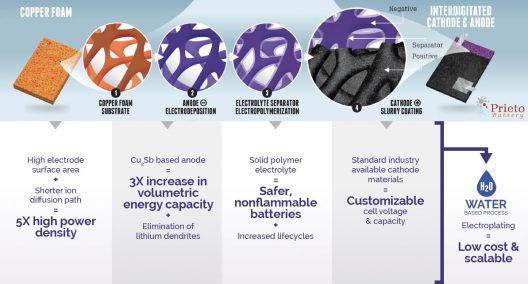

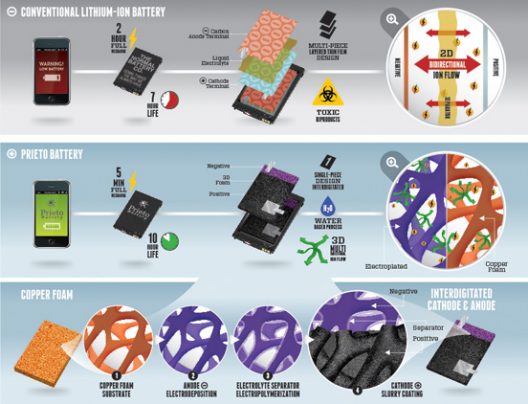

Prieto claims advantages based on its porous copper foam-based structure. Coated with “an ultra-thin polymer electrolyte and… surrounded by a cathode matrix,” the battery promises a power density comparable to super capacitors.

Its anode, coated with an electrodeposited copper antimonide (Cu2Sb) layer purportedly has an “unprecedented degree of stability,” excellent capacity and long-term cycling capability. Prieto claims the materials allow low-cost manufacturing and scalable production.

The patent-pending Cu2Sb copper foam substrate awaits a patent, its structure ensuring continuous electrical contact throughout the 3D anode. No costly annealing or other post treatment is required. The material is conformal and very thin “to allow for the subsequent interpenetration into the structure by the cathode material. This layer is pin-hole free, which is critical for the overall performance of the battery. The strict demands on the electrolyte form the basis for additional intellectual property protection.”

Prieto claims its cells will be able to achieve power densities of 14,000 Watts per liter, while maintaining energy densities of 650 Watt-hours per liter. Tesla’s 18650 (18 mm in diameter x 65 mm in length) batteries are calculated by Quora.com to manage 727 Wh/liter. Its 2170 (21 mm x 70 mm) cells achieve 885 Wh/liter, and in pack form, 805 Wh/liter. Power density for the Prieto battery is expected to reach 14,000 W/liter, considerably higher than more li-ion cells.

Whether the lower manufacturing costs will mean good sales for Prieto remains to be seen. We are seeing the battery at the beginning of a development cycle, so future releases may fulfill the promise seen in the different manufacturing and configuration approach. Prieto says it can make batteries tuned for energy or power and this flexibility may be its best selling point.