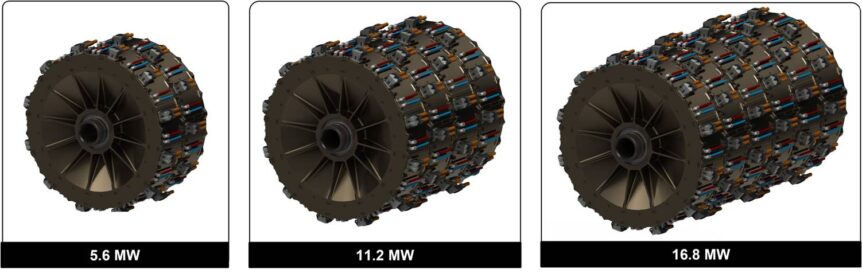

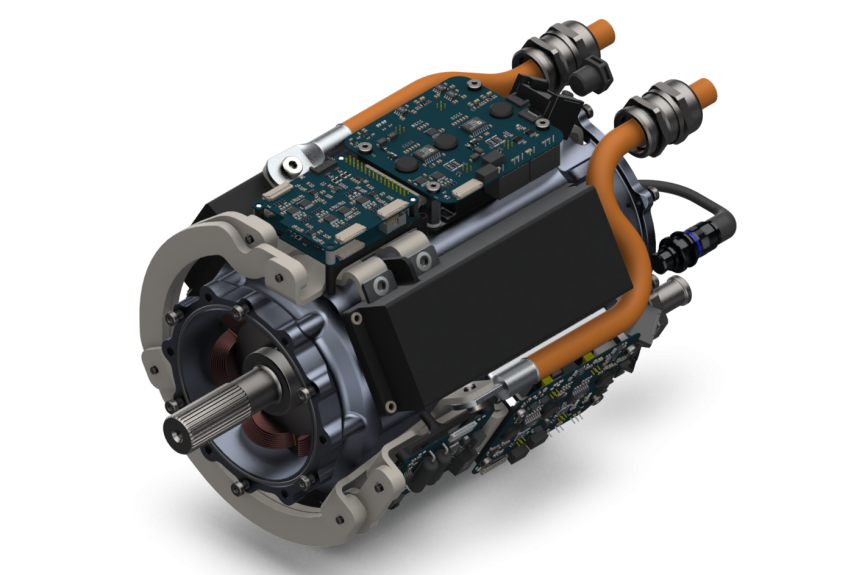

H3X is shaking things up with its announcement of its HPDM-3000, a three megawatt motor. Thirteen years ago, your editor gave his first presentation at an electric aircraft symposium, held that year in the Hiller Aviation Museum in San Carlos, California. Dr. Brien Seeley, founder and then head of the CAFE (Comparative Aircraft Flight Efficiency) Foundation, had asked for research on motors of 100 kilowatts or more. It was hard to find units of over 50 kW at that time, but people like Roman Susnik were managing ultralight motors of over 100 kW for motorized sailplanes With competitors like MagniX and ZeroAvia in the game, H3X introduces the HPDM-3000, a 2.8 mW (3,753 horsepower) ultra-high power density integrated modular motor drive (IMMD). Developed by a group of young graduates of the University of Wisconsin at Madison, H3X’s motors combine extreme lightness for the power produced with cutting edge manufacturing techniques. In this video, Chief Technology Officer Max Liben explains the …

H3X – A Motor with High Power Density

H3X, a motor company started by three University of Madison, Wisconsin graduates, promotes its integrated motor/inverter power plant as “the next step in the evolution of electric propulsion technology.” With Their HPDM-250’s 13-kilowatt-per-kilogram continuous power ability, it meets ARPA-E’s (Advanced Research Projects Agency–Energy’s) criteria for powering large, 737-type aircraft. Electronics Weekly reports, “ARPA-E has determined that for a Boeing 737 to complete a typical five hour flight, the propulsion system must be >12 kW/kg continuous.” H3X adds, “These specifications are estimates based on electromagnetic thermal and structural simulations. Data from dynamometer will be available Q2 2021.” Their motor is roughly twice as power dense as MagniX motors of similar power, according to H3X. Weight reduction is an intrinsic part of aircraft design. In the days of internal combustion engines (still very much with us), conventional wisdom held that reducing power plant weight by one pound could help take two pounds off the airframe. Even today, ICE engines generally produce only …