The three biggest words in battery structures are “Area, Area, Area.” The more anode and cathode area a battery can expose to the electrolyte that carries ions and electrons between the positive and negative ends of the battery, the better. Most battery configurations, according to researchers at Carnegie Mellon University and Missouri University of Science and Technology, block a great deal of interaction between these elements. Their solution is to go porous in a microlattice battery, thanks to 3D printing. Electrodes present some surface area to the electrolyte, which can only interact with the surface area presented. Rahul Panat at Carnegie Mellon and Jonghyun Park at Missouri S & T have created a cube-shaped battery composed of microlattice electrodes which present significantly greater amounts of surface area to the electrolyte. The title of their paper (with co-author Mohammad Sadeq Saleh) brings out this “area rule”: “3D printed hierarchically-porous microlattice electrode materials for exceptionally high specific capacity and areal capacity lithium …

Put Three Things Together – 3D, Aerogel, Graphene – and It’s Got to be Good

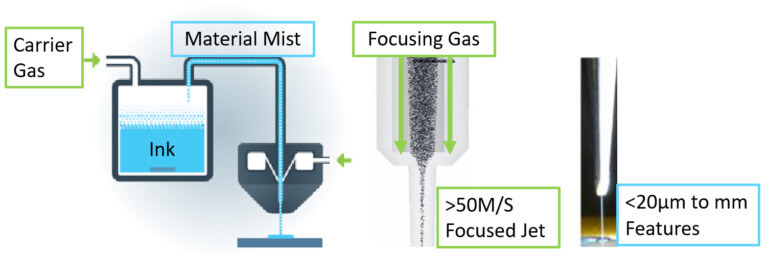

If there were a pantheon of technological hipness, right now three front-runners for induction would be 3D printing, aerogel and graphene. They all rank high on the disruptive technology scale, have enormous amounts of good press, and excite the imagination with their potential. Lawrence Livermore National Laboratory researchers have gone beyond combining chocolate and peanut butter by blending the three higher-tech ingredients into a rather amazing battery material with excellent electrical and mechanical properties. We have discussed the idea of structural batteries in this blog, and this new melding of technologies holds much promise. Aerogel, as defined in the Laboratory’s announcement, “is a synthetic porous, ultralight material derived from a gel, in which the liquid component of the gel has been replaced with a gas. It is often referred to as ‘liquid smoke.’” Lawrence Livermore researchers have used a 3D printing technique known as direct ink writing to craft an engineered architecture microlattice with well-defined pores – which are essential …