“The Quest for a Truly Practical Electric Touring Motor-Glider” Mike Friend is not your typical retired aircraft executive. As Technical Director for Boeing, he oversaw “the first manned fixed wing aircraft powered by a hydrogen fuel cell/lithium ion battery powerplant that first flew back in 2008.” He’s been associated with green energy projects since then, including work on the Boeing-supported Zunum project, a set of 10- to 50-passenger electric hybrid airliners. On the personal front, he hopes to design and build the Spark Solo, a single-seat electric motorglider that will enable cross-country flights from his home base of Bremerton (Washington) Regional Airport. Working with Gabriel DeVault Motorgliders make a good combination with battery power. Their clean lines enable using low power at cruise, and as this video from Gabriel DeVault shows, even a respectable takeoff and climb with power limited to 25 kilowatts (33.5 horsepower) in this instance. Normally, DeVault’s Sonex would make full use of its Zero Motorcycle motor’s …

Britain Puts an Electric Nose on a New Zealand Carbon Fiber Falco

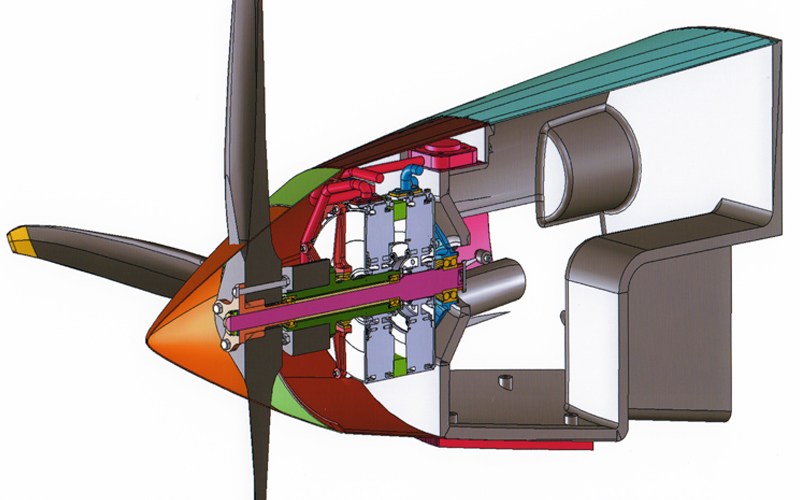

Richard Glassock, an Australian now working in Hungary, has been a presenter at an Electric Aircraft Symposium and received worldwide interest for his eight-passenger, open cockpit sailplane design a few years ago. He writes today to share news about a twin electric motor conversion for a Falco, the great, high-speed craft by Italian Stelio Frati. Originally designed for four-cylinder, horizontally-opposed engines of up to 300 horsepower, the wood airframe was incredibly complex and required thousands of hours to construct. Signor Aldini reported taking 80 hours just to make the main spar’s jig – with four people needed to complete clamping before the glue set. With the increasing difficulty of finding aircraft-grade sitka spruce or aircraft-grade wood craftsmen, those who can replace their time with money can purchase an all-carbon-fiber composite kit with qualifies under the FAA’s 51-percent rule – the homebuilder being responsible for 51 percent of the construction. All kits for the airframe, firewall back, total over $92,000 (U. S. …