Keeping battery fires at bay is a constant irritant, if not downright hazard, in the electric vehicle world. Battery fires are particularly scary in aircraft, where help may be 35,000 feet below. Three different solutions have been introduced by industry and scholars, though, and may reduce, or even prevent such unfortunate occurrences. That the three solutions were featured in the same day’s postings of GreenCarCongress.com is a bit astonishing, but heartening. The three contenders appear below. The Honeywell and Nexceris Sniff Test Honeywell has a strategic alliance with Nexceris, developer of the Li-ion Tamer (a horrible pun, as you may have noticed) lithium-ion gas detection solutions. Instead of waiting for things to heat up, as happens in thermal runaways, the Honeywell-Nexceris team will develop the proactive detectors, which “sniff” the fumes of an incipient battery fire before it can even start. Honeywell and Nexceris will work with EV makers to install Li-ion Tamer sensors “on their gas detection systems control …

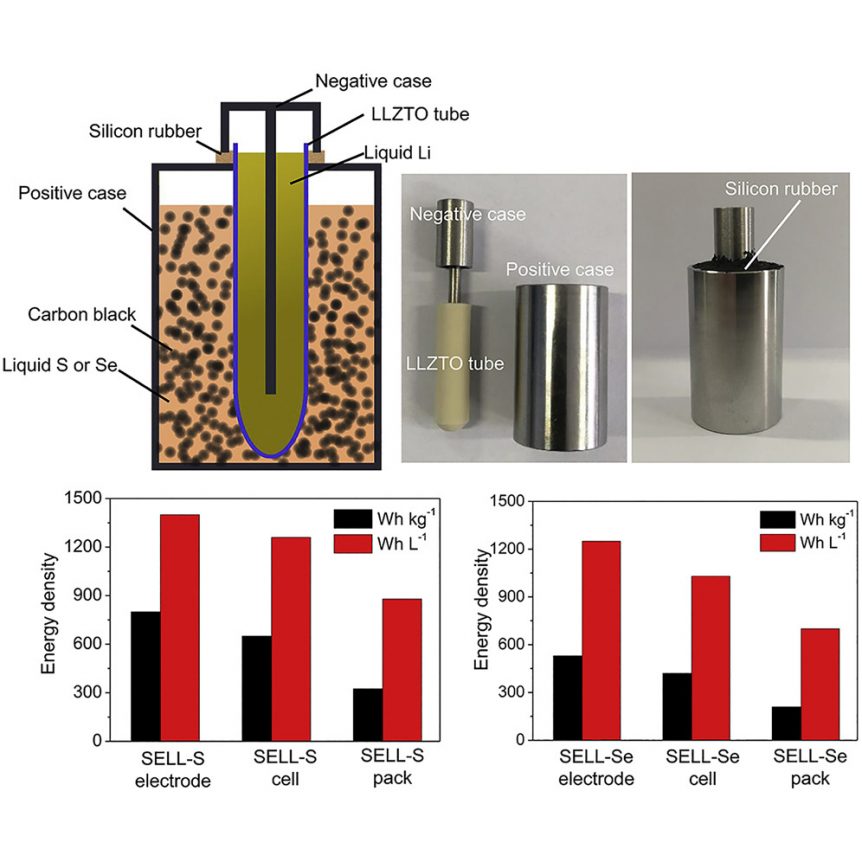

Solid State Lithium Sulfur and Lithium Selenium Batteries

In battery making, recipes for electrolytes play an important part of the whole. In a new formula whipped up by Zhengzhou University, Tsinghua University and Stanford University, Lithium (Li), Lanthanum (La), Zirconium (Zr), Tantalum (Ta), and Oxygen (O) form a ceramic tube as the battery’s electrolyte. This tube is centered in new solid state Lithium Sulfur and Lithium Selenium batteries. Researchers filled that tube with a liquid lithium electrode, and immersed the tube in a bath of carbon black and liquid selenium or sulfur in a stainless steel container. The team’s paper, “High Energy-Density Solid Electrolyte-Based Liquid Li-S and Li-Se Batteries,” published in the October 15 edition of Joule, explains the new batteries should be capable of delivering energy densities of around 2,600 Watt-hours per kilogram for the lithium-sulfur chemistry and 1,160 Wh/kg. for lithium-selenium. Currently, researchers have achieve 500 Wh/kg, double the best Li packs today. This can be achieved at cost of $41 per kilowatt-hour for the Li-Se …

Aluminum Yolks and Titanium Shells

A new “yolk-and-shell” nanoparticle could boost the capacity and power of lithium-ion batteries. MIT’s press release gives a graphic overview of what damages electrodes and shortens battery life. “One big problem faced by electrodes in rechargeable batteries, as they go through repeated cycles of charging and discharging, is that they must expand and shrink during each cycle — sometimes doubling in volume, and then shrinking back. This can lead to repeated shedding and reformation of its “skin” layer that consumes lithium irreversibly, degrading the battery’s performance over time.” Dr. Yi Cui and teams at Stanford’s National Accelerator Laboratory (Formerly the Stanford Linear Accelerator Center), and the Environmental Molecular Sciences Laboratory (EMSL) at Pacific Northwest National Laboratory all published papers on a similar joint accomplishment three years ago, as reported in this blog. Dr. Cui had studied several alternative ways to reduce the effects of expansion and contraction on electrodes. According to an MIT news release, “Now a team of researchers at MIT, led …