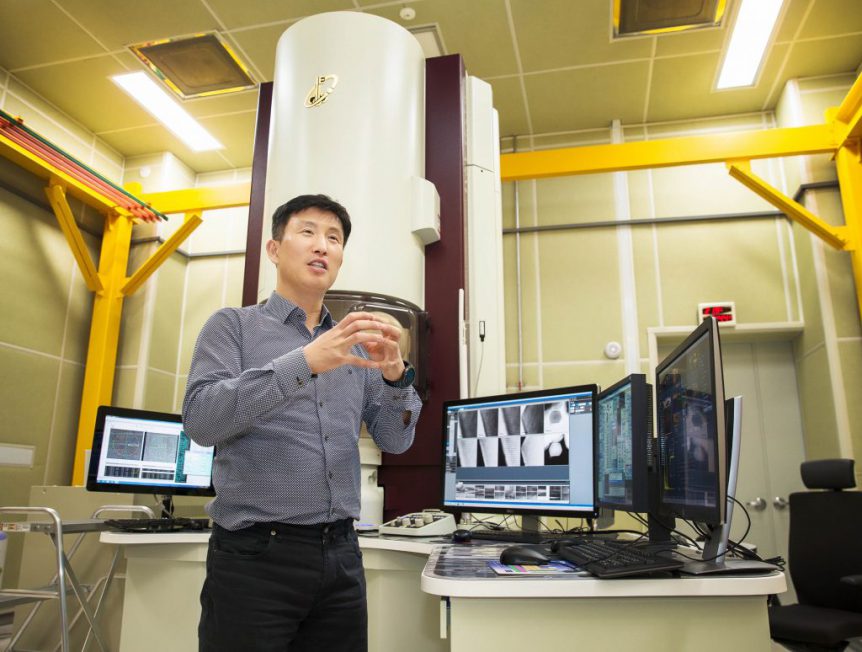

Jaephil Cho has a surprise for us – an aluminum-air battery that is potentially (no pun intended) more energetic than gasoline. Director of the Research Center for Innovative Battery Technologies and Professor in the School of Energy and Chemical Engineering, at Ulsan National Institute of Science and Technology (UNIST), Cho and his students have released over 350 papers, including one titled, “Seed-mediated atomic-scale reconstruction of silver manganate nanoplates for oxygen reduction towards high-energy aluminum-air flow batteries.” While such titles might not get him on the NY Times best-seller list, Cho is widely respected, UNIST reporting he has been named to the 2017 Highly Cited Researchers List in materials science, a second such honor for him. Professor Cho’ Surprise Professor Cho’s paper (in full) describes the aluminum flow battery he and his team developed. According to the UNIST News Center, “…Compared to the existing lithium-ion batteries (LIBs), the new battery outperforms the others in terms of higher energy density, lower cost, …

Making Silicon Anodes in Large Batches

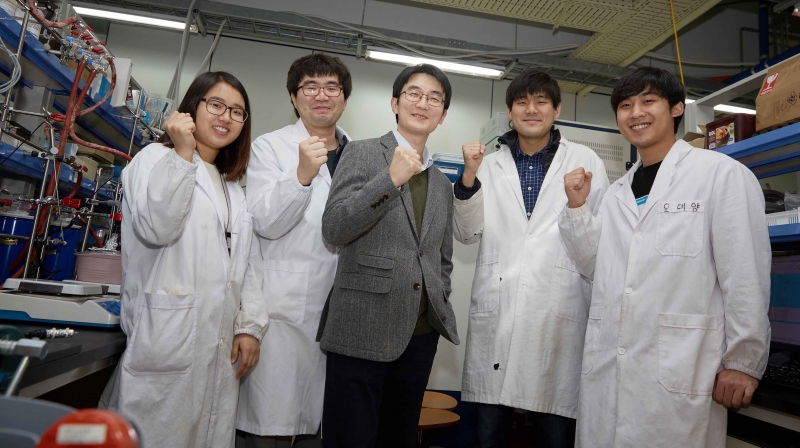

A Long-term Collaboration Dr. Jaephil Cho is a well-known battery researcher and inter-continental associate of Dr. Yi Cui of Stanford University. The pair has collaborated on many ways to improve battery performance and longevity, and both have appeared at various electric aircraft symposia. They have even inspired others in related research. Dr. Cho and his team at Ulsan National Institute of Science and Technology (UNIST) in South Korea announced a way to make a new generation battery anode material – a big move toward mass production of improved cells. Dr. Cho’s team of researchers affiliated with Ulsan National Institute of Science and Technology (UNIST), South Korea, claims to have made yet another step towards finding a solution to accelerate the commercialization of silicon anodes for Lithium-ion batteries. A Next-generation Hybrid Anode As reported by UNIST, “Prof. Cho and his research team have developed a new type anode material that would be used in place of a conventional graphite anode, which they …

Deformable Flexible and Conductive – A Great Solid Electrolyte

Reporting on a new material that doesn’t seem real, a joint research team from Ulsan National Institute of Science and Technology (UNIST) and Seoul National University in Korea says it has developed a “highly-conductive, highly deformable, and dry-air-stable glass electrolyte for solid-state lithium-ion batteries. If those characteristics seem mutually exclusive, the electrical performance helps dispel skepticism. Assisted by colleagues at Lawrence Berkeley National Lab and Brookhaven National Lab, the researchers prepared the electrolyte using a “homogenous methanol solution,” and wetting exposed surfaces of the electrode active materials with the solidified electrolyte. Eureka Alert! quotes Professor Yoon Seok Jung (UNIST, School of Energy and Chemical Engineering) , “The research team also developed a material for the solid electrolyte by adding the iodized lithium (LiI) to the methanol liquid which is the compound (Li4SnS4) based on tin (Sn). The compound’s ionic conductivity was originally low, but it got increased by getting mixed with LiI. Consequently, by combining two materials together, it became possible to …

Cheap and Dirty Fuel Cells – Good News for Hydrogen

Hydrogen fuel cells would be just about the most wonderful power producers in the world if they weren’t so expensive and so finicky about their diet of hydrogen. Their catalysts, usually made of costly platinum, can be destroyed by impurities in the gas. Making high-purity hydrogen is an exacting task and adds to the expense of operation. Two studies by scientists at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory; one in conjunction with researchers at South Korea’s Ulsan National Institute of Science and Technology (UNIST), Korea Institute of Energy Research (KIER), show that it may be commercially possible to make less expensive catalysts with available materials, and in one case, use “dirty” hydrogen that would otherwise destroy fuel cells. The reduced price of making such hydrogen would further add to operational economies. Green Car Congress reports that Brookhaven and UNIST have discovered, “a new family of non-precious metal catalysts based on ordered mesoporous porphyrinic carbons (M-OMPC) with high …