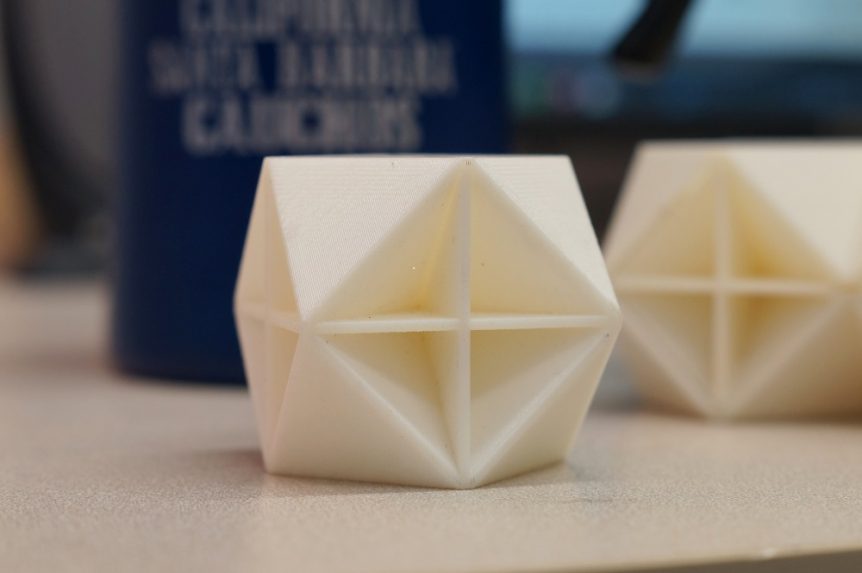

Jonathan Berger has come up with a foam structure that will make it more than the ephemeral filling in composite construction sandwiches. Isomax™ foam could be the entire structure because of its unique geometry. He claims it to be the world’s first material to achieve structural performance predicted by theoretical bounds. His letter in the journal Nature describes the geometry Berger and his collaborators created to enable such lightness, strength, and versatility. Berger, a postdoctoral researcher at UCSB’s mechanical engineering department, worked with mechanical engineering professor Robert McMeeking and materials scientist Haydn N. G. Wadley from the University of Virginia to prove the ideas Berger first conceived in 2015. This solid foam, “a combination of stiff substance and air pockets,” uses three-dimensional pyramid and cross cell geometry to achieve high stiffness. The ordered cells are set apart by walls forming three sides and a base, and as octahedra, reinforced inside a “cross” of intersecting diagonal walls. This “mostly air” structure …

FAA Awards for Commuter Liners of the Future

In a series of far-reaching competitions for university students, the FAA has opened the gates on innovation for new aircraft and airport infrastructure design. Announcing the winners of its Design Competition for Universities, the FAA awarded three prizes in the Electric/Hybrid Electric Aircraft Competition. In doing so, it acknowledged the pioneering work of the CAFE Foundation and NASA in promoting the original Green Flight Challenge, generously supported by sponsorship from Google. “Recently, the Green Flight Challenge and efforts of general aviation manufacturers and others have demonstrated flight using electric motors on general aviation aircraft. Under NASA’s Subsonic Fixed Wing Project, aircraft and engine manufacturers identified key technology capabilities required for electric and hybrid-electric propulsion of single aisle aircraft, expected by 2030.” To expand on the promise of the GFC, the FAA requested that competition entrants design, “…a regional size aircraft (25-50 seatclass) that uses electric or hybrid-electric propulsion with a cruise Mach of 0.72 – 0.8, 500 nm range and …

Yet Another Printed Airplane, And a Plastic Rolls-Royce Turbofan

Fariss Samarrai of the University of Virginia reported on two fellow students and a faculty advisor who “printed” a two-meter (6.5 feet) wingspan airplane. Third year engineering student Steven Easter was part a group that “built” a one-quarter scale Rolls-Royce turbofan replica using 3D printing, a method in which components are created from thin layers of material fused together. Because the material used was plastic, the engine cannot be “fired up,” but is run with compressed air. It would be nice to think that all the pieces come out neatly finished and ready to go, but in this project, students had to add a great deal of hand finishing and assembly. According to Popular Mechanics, “…[faculty advisor David] Sheffler gave the students CAD (computer-aided design) files for the 43 parts of the replica engine. But it wasn’t as easy as just plugging those instructions into a 3D printer. The students modified and refined those designs to ensure that the engine would …