Fraunhofer and the Hochschule Esslingen University of Applied Sciences have created an electronic race car that they will show at the Sensor + Test Measurement Fair in Nuremberg, Germany from May 14 through 16. Not only electrically driven, the innovative vehicle holds a number of sensor and control systems that might be of interest to electric aircraft designers.

EVE, the electric racer from the Hochschule Esslingen University of Applied Sciences, is loaded with sensor and intelligent systems. Photo courtesy E-Rennstall, Hochschule Esslingen

EVE, the product of the school and Fraunhofer’s labors, can sprint from 0 to 100 kilometers an hour (62 mph) in 3.6 seconds with its twin 60 kilowatt, 4,500 rpm motors, and reach a top speed of 140 km/hr (86.8 mph). Its 8 kilowatt-hour lithium polymer batteries allow only a short run of 22 kilometers (13.64 miles) though, not surprising in terms of high power outputs pulling the cells down quickly.

Electrical engineering students from the e-racing team at the Hochschule designed the 300 kilogram (660 pound) car as an elective project to augment their studies, and ran it at the International Formula Student Electric (FSE) race in Italy.

Students received high-powered help from the Fraunhofer Institute for Integrated Circuits IIS in Erlangen, who developed an intricate sensor system along with Seuffer GmbH & Co.KG, an industry partner with whom the institute has been working for over 11 years. Seuffer also sponsors the students of the E.Stall racing team.

EVE is a test bed and demonstration platform for multiple sensor technologies from Fraunhofer, including those that monitor braking pressure, crashes, temperature and acceleration, accelerator and brake pedals, speed, steering angle, wheel speed and power. Fraunhofer explains, “These last six functions could all be performed by HallinOne® sensors developed by Fraunhofer IIS, 3D magnetic-field sensors that are already a standard feature in washing machines, where they are used to determine the position and orientation of the drum.” The painfully punned sensor name gives a whole new meaning to taking the car out for a spin. (apologies to one and all.)

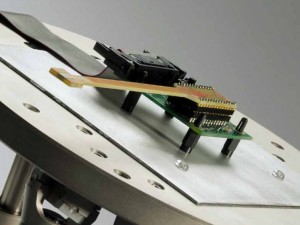

- Hallinone sensor performs a multiplicity of tasks in EVE race car

Not content to monitor all the salient functions of the car, the team expanded the normal roles of motor and battery management. Two electronic sensors attached at the sides of the batteries use 3D magnetic-field sensor technology to monitor battery charge. According to Fraunhofer, “What’s special about this is that the contactless sensors measure both the current that flows from the battery to the engine and the current that flows back again when the vehicle brakes. The integrated sensor system is able to eliminate disturbances and foreign magnetic fields, thus guaranteeing very precise measurements. A further advantage is that the system is also able to measure other aspects of the battery such as its voltage and temperature. The data is collected and sent to the power control unit (PCU) and the battery management system (BMS), which controls the charging and discharging processes.” This would certainly have an application in aircraft with regenerative capabilities in gliding or descents.

The video demonstrates many potential applications of Hallinone technology, but comes in for a hard-sell landing at the end.

The BMS determines the impedance spectrum of all battery cells and constantly tests whether cells are functioning properly, allowing determination of condition, current capacity, potential service life, and prediction of running times.

To help squeeze the last bit of energy from the cells, the BMS balances weak and strong cells. As Dr.-Ing. Peter Spies explains, “Until now, a battery system was able to provide only as much energy as was available in its weakest cell. The energy stored in other cells remained unused. Our BMS has an active cell balancing system that moves energy between stronger and weaker cells. This means that all cells share the load equally, allowing the maximum capacity of the battery as a whole to be utilized…. EVE’s current BMS is a system developed in house by E.Stall, but our solution could take its place,”

EVE has one last trick on her dance card – POLKA, a polarization camera that measures stresses within unpainted surfaces of the car’s carbon fiber structure. “This compact camera makes any scratches visible by registering properties of light that are imperceptible to the human eye: polarization. Material stresses in the plastic cause changes in polarization. POLKA is able to collect all the polarization information for each pixel in a single shot at speeds of up to 250 frames per second. Using real-time color coding, the dedicated software translates the information collected about the intensity, angle and degree of polarization into a visual display that is accessible to the human eye.” This latter technology would be helpful in a Pipistrel or a Dreamliner.