United Technologies Research Center (UTRC) is working with the Advanced Research Projects Agency – Energy (ARPA-E) on the “Additive Manufacturing of Optimized Ultra-High Efficiency Electric Machines,” or making motors through 3-D printing with metals, possibly obviating the need for rare-earth elements.

The $2.7 million ARPA-E award will fund the East Hartford, Connecticut-based project through early 2016 and may lead toward the goal of creating lower-cost, more efficient motors.

Because modern permanent magnet motors require rare earth minerals in their magnets for maximum performance, manufacturers must make optimum use of these minerals with minimum waste to be successful. Because these minerals do not exist in large quantities in North America, makers must import a great many of them from Asia, where certain key players maintain control over their distribution.

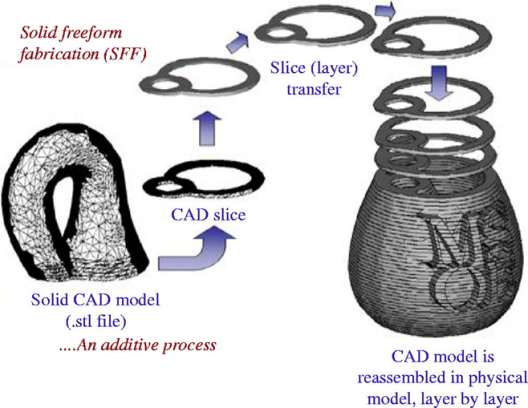

Instead of starting with a solid block of material and removing the unnecessary parts, additive manufacturing builds layer upon layer

ARPA-E explains the “workaround” possible through improved manufacturing techniques. “Rare earths are naturally occurring minerals with unique magnetic properties that are used in electric vehicle (EV) motors and wind generators. Because these minerals are expensive and in limited supply, alternative technologies must be developed to replace rare-earth-based magnets in motors and generators. Alternatives to rare earths will contribute to the cost-effectiveness of EVs and wind generators, facilitating their widespread use and drastically reducing the amount of greenhouse gases released into the atmosphere.”

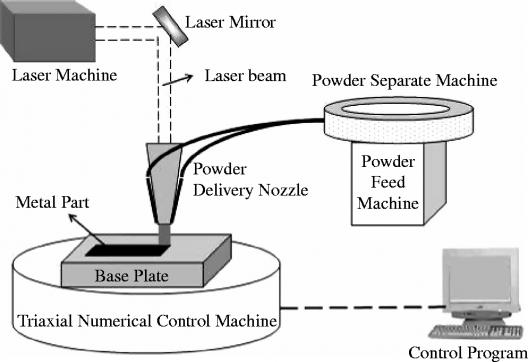

United Technologies has adapted additive manufacturing techniques (3-D laser printing) to produce an “ultra-high-efficiency electric motor for automobiles” that does not rely on rare earth materials, but does use a laser to deposit layers of copper, permanent magnet materials, and insulation onto an ever-expanding motor. UTRC’s process does not eliminate rare-earth elements entirely, but does reduce the amount required, optimizing its placement within the motor. UTRC’s hoped-for outcome is to “reduce the need for rare earth materials, thus limiting their cost and improving their performance.”

This will enable manufacturing of competitive motors without the supply security issues associated with importing the necessary materials, “and will have a positive impact on our national economic and energy security.” As electric motors become more widely adapted in transport, the need to import foreign oil or impact our environment to extract fossil fuels will diminish, leading to improved air and water quality, as well as health benefits for all.

Not only does this type of process reduce the amounts of rare materials needed, but because it normally starts with metallic powders layered and melted onto one another, eliminates the tradition approach to taking a large block of material and machining away the excess – which usually ends up as scrap, and might be recycled. It takes energy to make each pound or kilogram of the original material, though, and if only that necessary amount is added to a growing product, material totals start smaller and are used only as needed.

This research is being assisted by the Connecticut Center for Advanced Technology, Pennsylvania State University, and Ricardo, Inc., a long-time developer of high-performance engine and motor technology.

The Connecticut Center sees many applications for its involvement with additive manufacturing. “Additive Manufacturing via Laser Engineered Net Shaping (LENS) that forms solid metals from powder for aerospace alloys provides manufacturers a unique capability for ‘growing’ parts with complex geometry and for the repair of high value parts that are worn or damaged.”

To show one possibility for making motors, researchers at the University of Texas at El Paso’s Keck Center crafted this simple motor with additive manufacturing. It does require significant manual labor, but a process proposed by Brien Seeley could reduce the amount of human intervention.

“Imagine just 3D printing an entire motor, in which the ink jets squirt out yttrium, beryllium, copper and carbon in a just-right pattern to maximize magnetic strength, dimensional clearances, weight savings, etc. Imagine doing it for 200 kW motors and for 0.2 kW aileron servo-motors. Really exciting stuff. Maybe the printing starts with a sturdy steel shaft with an SAE prop flange and just builds the motor right onto that shaft.”

With the rapid strides we’re seeing in 3-D printing, additive manufacturing, or whatever computer-based processes come next, such visions may already be realities in labs around the world.

Comments 1

Fantastic work.