In his presentation at AirVenture 2009, George Bye, CEO of Bye Energy, set forth some ambitious goals for his company. This included the development of a hybrid electric power system for light aircraft (under 250 horsepower) with target markets for general aviation and experimental homebuilt aircraft. Bye explained that light, powerful electric motors and Lithium-ion batteries have achieved a mature technology level that makes this an ideal time to enter this new market. On February 18, Bye introduced the proof of concept systems that will enable him to achieve this.

Charles B. Johnson (left) and George Bye, COO and CEO of Bye Energy with POC airplane

The Green Flight Project consists, in its first phase, of an electric motor based on the UQM 125, a 90-pound, 95-percent efficient unit that puts out up to 168 horsepower (output of the initial POC motor will be closer to 100 horsepower). A set of battery packs, totalling 200- to 300-pounds will provide power, and a dedicated motor controller and battery management system (BMS) will keep things cool and under control. The system, approximating the weight of current internal combustion engine and fuel systems, will be installed in a mainstream two-seater, with potential for development in Light Sport Aircraft (LSA), FAR Part 23 (what we think of a “light” aircraft), and experimentals. Bye hopes that work with UQM will lower the motor weight to 65 to 70 pounds, a first step in refining the proof of concept. Later, the system will be augmented by an yet undefined hybrid component, and by solar films from Ascent Solar, which Bye claims could support up to 20-percent of a typical light airplane’s energy needs.

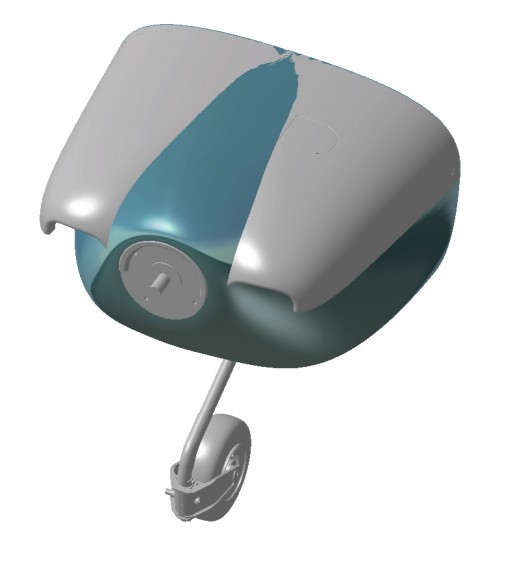

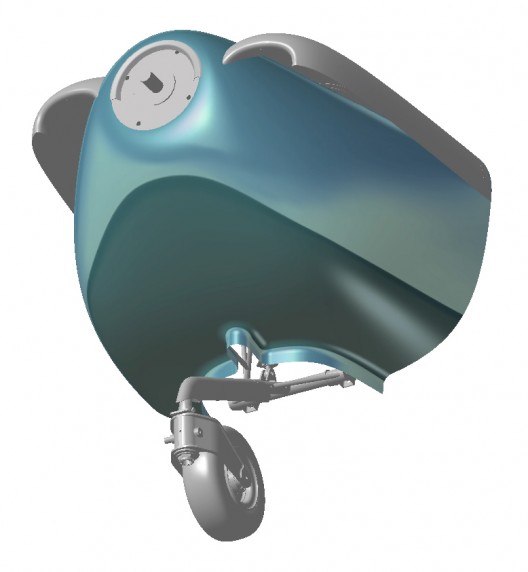

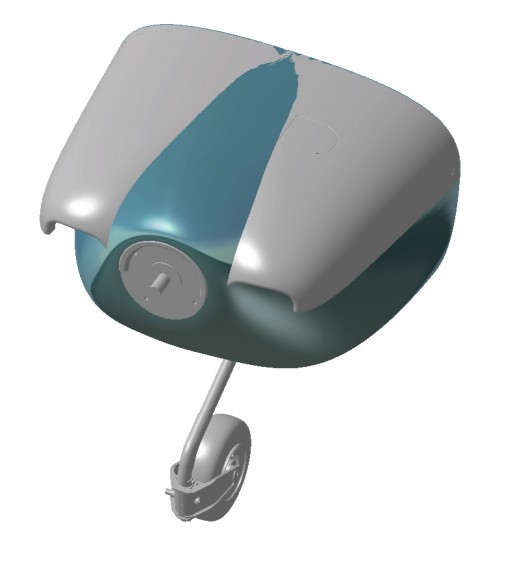

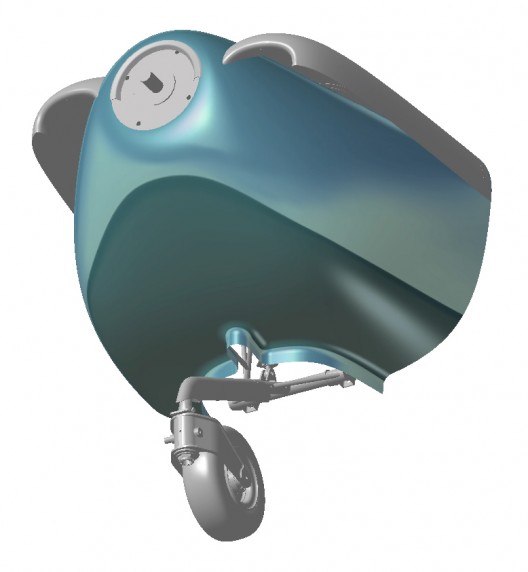

Improved cowling (blue) compared to original, IC engine cowling

less frontal area, and lack of cooling drag improve performance

Bye notes that the average age of the 200,000 general aviation fleet is 33 years, with the highest point of light aircraft production coinciding with this figure – 14,000 units in 1977. Bye feels that this helps to explain the dropoff in interest in flying among young people. Imagine a 17-year old who’s accustomed to state-of-the art electronics, and who owns a full contingent of video games, iPhones, laptops, notebooks, etc. Take him for an introductory flight and immerse him in a noisy, fume-spouting mechanical museum piece. Light aircraft simply have not kept up with the constantly emerging areas of electronics, or even the impressive gains in automotive technology.

Bye projects a market of up to 950 of his systems mounted on new or retrofitted general aviation aircraft between 2010 and 2015, with a further 3,325 systems between 2015 and 2020, if he can meet market share goals. He foresees sales of 350 systems for new and retrofitted experimental aircraft during the first half of this decade, rising to 825 in the latter half. “Retrofit” is an important word here, because the system is meant to be adaptable enough for a wide variety of existing aircraft, with little change in weight and balance characteristics overall. Technology also plays a part, with battery and motor improvements about to go from a fairly linear progress curve to an exponential development surge. Things will get lighter, more reliable, more powerful, and less expensive over time, emulating trends in the electronics industry. Charles B. Johnson, Chief Operations Officer for the firm, affirms this new direction. “The time to accelerate incorporation of this new hybrid technology has arrived. General Aviation is a vital market that will benefit from the environmentally friendly, lower cost, more efficient and higher performing aircraft.”

The current state of general aviation may seem a hindrance for its immediate salvation, but Bye sees this as an opportunity for entrepreneurs like him. “We are hoping to invigorate and revitalize the industry. This proof of concept is a first step in that challenge.”

Comments 5

Dean,

We hope this is the beginning of a conversation that helps move general aviation into next generation propulsion. A couple of points of clarification: The average four seat aircraft is 38 years old. The cowling images contrast a new reduced drag (blue) electric design, as compared with the original (grey) conventional design. This is due to the virtual elimination of the substantial cooling intake required, along with the larger size of a convential internal combustion engine over an electric motor of equal horsepower.

George Bye

(Editor’s note: Thanks to George Bye for the clarification and the explanation of his cowling illustrations.)

George,

The new cowling is interesting in that it has no cooling inlets, but I see something that is disturbing in the cooling exit. The cooling exit ramp that is provided is rather large and at a very high angle. While this will make for some nice cooling it will also add quite a bit of drag. If there was a need for cooling, which I imagine that there still is, then you could make the cowling exit have nice clean curves, and lower the cowling exit below the waterline of the fuselage. It would clean up the shape, as well as clean up the drag.

Adam

(Editor’s Note: I asked George Bye to respond to this comment, and he provided the following. This is the type of dialogue we encourage through this blog, as it will lead to improvements, refinements, and maybe even breakthroughs.)

Adam,

Interesting comments.

The emphasis at this point is not the details of the CAD rendering on the website, but rather the broader concept of reduced cooling drag overall, together with a smaller propulsion system cross-section. In theory, there is only a need for a ‘small’ amount of cooling (and temperature management as a broad topic area) – however, this is one of the areas of great interest in upcoming flight test.

Best Regards,

George Bye

Kudos to Bye Energy for undertaking this project. As a fairly new private pilot (all time logged in C172’s so far), the promise of cheaper and greener forms of flight propulsion is definitely needed. Light Sport Aircraft (with their less burdensome certification requirements) are the perfect platform to bring electric aircraft to the U.S. general aviation market. If a hybrid electric system can be priced competitively with standard (e.g. Rotax and other low-lead avgas) LSA piston-engine systems, the advantages will be obvious and the chances for market success should be excellent. Best wishes to Bye and company in this endeavor.

George and Charlie

I’m so impressed with the concepts and the goals you have developed so far and I’m sure the general aviation industry is primed and ready for your break through. As a member of the EAA and a former long-time Cessna employee, I’m excited to see some folks with a positive attitude these days and a vision of general aviation rebirth! I would love to be a part of this, what can I do to help?

Bill Plucker

Wichita, KS.

Update 2012: While the electric Cessna program continues to advance under the leadership of Charlie Johnson and a new name “Beyond Aviation”, we have continued our research into solar-electric hybrid propulsion in unmanned aircraft. At the early August 2012 AUVSI conference, my company, Bye Aerospace together with Silent Falcon UAS Technologies, unveiled a small solar-electric powered drone. The remarkable economics and technology is proven and the performance benefits have been demonstrated. A quick ‘Google’ search of ‘Silent Falcon Bye Aerospace’ will give a number of images and background information.