Jeffrey Engler of Wright Electric posted an item about Charge CCCV, LLC (C4V) which “demonstrated a prototype of its new Solid State Battery (SSB) at the NY BEST 2018 Fall Conference in New York. The Company’s SSB solution delivers higher performance, higher density, lower cost batteries that promise to require significantly less charging time than others.” The startup announced a 380 Watt-hour-per-kilogram battery already in production. Since your editor tends to become a bit snarky about the usual two-to-five-year period of anticipation before these numbers become reality, he rushed to check out the claims.

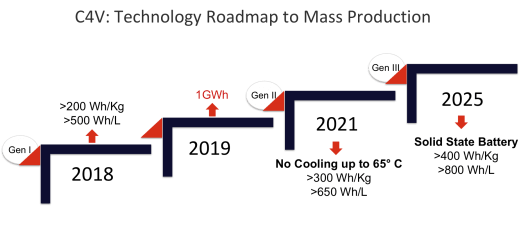

Will the one gigawatt-hour plant be open by 2019 – or 2021. Differences between the time scale and C4V’s text leads to some confusion – at least for your editor

Plausible Numbers, but Uncertain Time Frame

The firm’s numbers are not wildly excessive, and they seem to be getting funding and finding partnerships with established companies. The video is not great proof of anything other than that a metal box with the company’s logo exists. Their web site gives credibility to their ability to produce actual batteries.

According to C4V, “Approximately 80% of the cost to produce lithium ion cells originates from four major components: the anode, cathode, separator, and electrolyte.” The company has “discovered, patented and commercially developed” anodes, cathodes and at least 15 other sub-component for their batteries and created means of manufacturing cylindrical, pouch and prismatic cells. Their approach avoids high temperatures and chemically toxic treatments of materials and provides high yields for components. The company says they have achieved 70-percent yields compared to 40-percent for similar processes for the industry in general. Their processes also use less energy and allow lower costs for final products.

Their chart of projected energy densities seems at odds with some of the company’s texts, but the more conservative numbers are probably plausible. Overcoming one major problem in creating silicon electrodes, C4V says its, “…composite silicon technology prevents catastrophic volume expansion via nano-structuring. By allowing the primary particles to expand internally and not crack, structural integrity is maintained and improved performance is achieved.” This ability to retain silicon’s structure despite its swelling and flexing under charge and discharge has plagued battery developers for years. C4V’s solution, if as effective as claimed, would be a major breakthrough.

In its second generation, C4V hopes to expand the temperature range in which its electrolyte can operate. This is a constraint in conventional liquid electrolyte batteries, but C4V is pushing toward higher percentages of solid-state materials. The company will also focus on optimizing electrode formulations.

Third generation cells will be available commercially in 2025, taking us to a seven-year wait. C4V diminishes our hopes for a near-term battery with which to power our aircraft and give our cars 500-mile range. “Our initial tests from Generation 3 batteries demonstrate energy densities and volumetric capacities of 400Wh/kg and 800 Wh/L. We confidently project these unique batteries will be ready for volume manufacturing by 2025 along with a stable supply chain.”

But Wait! or But…Wait.

This seems to contrast with the overview for their technology, which states the current energy density of 380 Wh/kg. C4V adds that they have been able to replace up to 80-percent of liquid electrolytes. Further, they state, “the Company is already targeting a 400Wh/kg and 750 Wh/liter milestone within the next six month timeframe before commercial process optimization starts. In the first half of 2019, C4V plans to announce the availability of its commercial cells to the market.”

With others such as OXIS Energy and Sion Power pushing those (or better) energy and volumetric densities, C4V possibly needs to update their time scale. It also needs to reconcile visual charts with their texts, with the hope that will clear up what seem to be inconsistencies in their presentations.

The firm has partnerships with “Magnis Resources, an Australian company specializing in end-to-end sourcing of raw materials for LIB manufacturing, and Boston Energy and Innovation, an ethical investment house responsible for financing and fostering sustainable energy solutions.” That group will produce an Imperium 3 battery line by 2021 at a planned gigafactory, probably in in the state of North Rhine Westphalia Germany.