Your editor has been on a road trip for several days, visiting the great Motel 6’s of California, and incidentally dropping in at Corning, California to stock up on olives and meet with Brian Carpenter, head of Rainbow Aviation. He holds forth there as dealer for the full line of Quicksilver ultralight aircraft, does flight training, and with his wife Carol, presents training classes on repairing ultralight, light sport, weight shift, and even powered parachute type aircraft. The pair has written several books on these topics.

Brian recently teamed with Quicksilver to manufacture a kit aircraft that will eventually include one or more electric motors for propulsion. With many ingenious features and a low introductory price, the all-metal airplane could become an introductory trainer for novice ultralight pilots. He and Quicksilver held a joint press conference at Airventure 2013 to announce the new machine.

Fitting easily into ultralight weight requirements, even with a motor and batteries, the EMG-6 (electric motor glider-6) two-seater offered by Tangent Aircraft, another Carpenter enterprise, has ample room for student and instructor.

EMG-6 shows welded steel tubing fuselage and aluminum tail boom. Boom was built from a set of kit parts in four hours.

With wings still on their way from Quicksilver, a partner on this design, Brian was happy to show the fuselage and its many features. To enable a narrow configuration for trailering or storage, for instance, Brian created a way to fold the horizontal stabilizer without the need to disconnect the control linkages at the tail.

Brian demonstrates horizontal tail folding, which requires the removal of only one bolt on each side

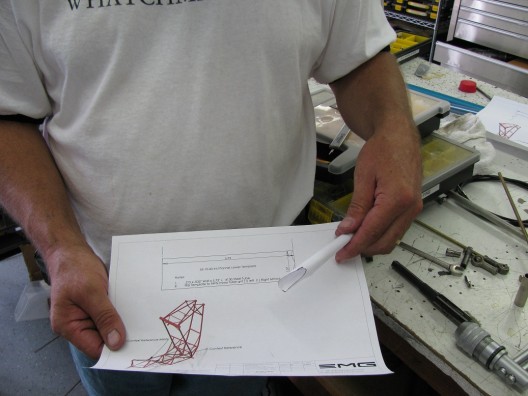

To keep kit costs low, he came up with a clever way of helping homebuilders cut and trim steel tubing to exact dimensions and angles. On his proof-of-concept EMG, he used only a hacksaw and a simple bench grinder to cut and finish the tubing for each piece that goes into the fuselage structure.

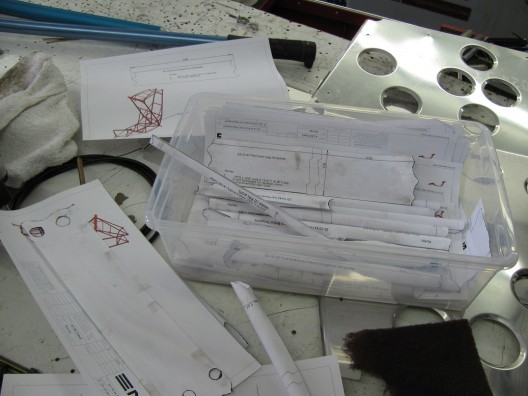

Builders will receive a set of tubing with isometric CAD drawings and a set of paper patterns numbered to match tube numbers on the drawing. Each pattern can be cut out, wrapped around the match-numbered tube, and used as a guide for cutting and final fitting.

For those who might already have a stockpile of tubing from previous projects, Brian is happy to supply the necessary drawings.

Until the FAA rewrites the current laws for Light Sport Aircraft that limit power to reciprocating piston engines, Brian will sell kits as gliders. Once the laws become more inclusive of a variety of “powerplants” including electric motors, he has several options available for research.

The idea of a self-launching, ultralight glider, with a motor and propeller weighing less than 5.5 pounds may sound unlikely, but Brian has demonstrated the necessary thrust from a very lightweight package. “Our current choice of power plants is the Plettenberg Predator 37 motor [producing] 15 kW (20 hp) and 99.3 pounds of static thrust utilizing the 33 inch diameter three bladed propeller.” Total weight with carbon-fiber prop is 5.3 pounds.

He is discussing needs with the Plettenberg factory in Germany, where they are now producing the Nova 15 and Nova 30 motors, discussed in this blog a few months ago. The 15 weighs 2.5 kilograms (5.5 pounds) and generates 15 kilowatts (20.1 horsepower): the 30 weighs 5 kilograms (11 pounds) and makes 30 kW (40.2 hp) at around 3,300 rpm.

At this time, Brian hopes he can demonstrate successful towing of his training glider to help keep instruction costs low – a key to luring new pilots and those who might have bailed out of perfectly good airplanes because of extreme costs.

The final product will be nicely finished. All metal will be powder coated or anodized as appropriate, and the tail coverings we saw are well-fitted and taut. We can only hope for the success of such enterprises because that will benefit all in aviation.

Comments 5

Bravo to the Carpenters for keeping their focus on AFFORDABLE two-seat aviation! Can’t wait to see the EMG-6’s development into an available, cost-conscious kit.

And bravo for your paper patterns for cutting tubes! I too am a strong believer in tubes and simple aerodynamic fairings.

This is very exiting. I am a Sport Pilot with about 135 hours in a J-3 Cub and 23 Instructional flights in a Schweizer 233 Glider. I would hope that this becomes a reality. This is the first offering of a Glider that can be built from a kit that I have seen.

Are any parts of this kit now available for purchase. If so what are they, and if not, what would be you’re best guess as to when some parts could be ready for shipment?

Ed

(Editor’s Note: Brian Carpenter and his team are working on getting the kits together. See his ongoing progress story at http://www.electricmotorglider.com/index.html.)

What would it cost to purchase the pre manufactured welded up fuselage without it being powered coated? I would be very interested if it could be purchased in this configuration. Please get back to me when you can.

Thanks.