Over the years reporting on battery developments, we’ve seen paper batteries, spray-on batteries, structural batteries and many types of material mixes. Drexel University has tossed all the above intone big hopper and come up with MXene, a potentially dynamic way of making batteries, supercapacitors, antennas, and structural elements that can be conductors, semiconductors, and insulators, among myriad applications.

Going Through a Phase

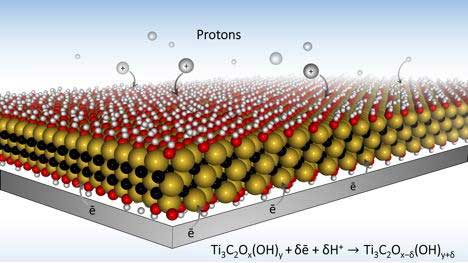

MXenes are formed from layered MAX phases, defined by Drexel as forming, “A large family of ternary(composed of three) carbides with the general formula Mn+1AXn, where n = 1–3, M is an early transition metal, A is an A-group element (mostly IIIA and IVA), and X is C and/or N:” That level of chemistry is two quantum leaps above your editor’s pay grade, so you’ll have to work out the implications for yourself.

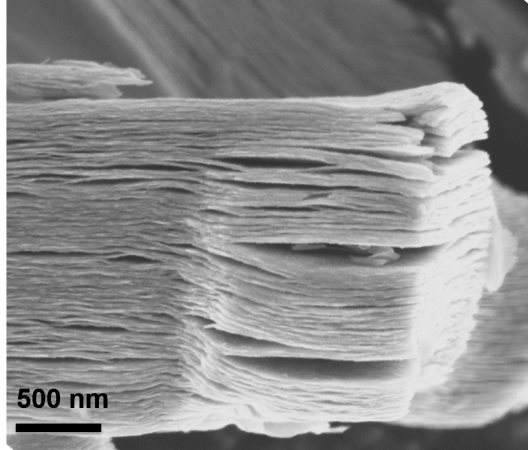

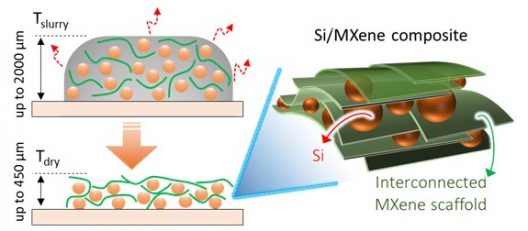

peeling layers from the MAX phase produces specific characteristics for new materials. Mixing this with the MXene slurry enables a protected anode

Or, you can read the more understandable explanation in this link.

Drexel explains, “MXenes are made by chemically etching a layered ceramic material called a MAX phase, to remove a set of chemically-related layers, leaving a stack of two-dimensional flakes. Researchers have produced more than 30 types of MXene to date, each with a slightly different set of properties.”

The research group Used two of them the to make the silicon-MXene anodes for testing: titanium carbide and titanium carbonitride. Researchers made another anode from graphene-wrapped silicon nanoparticles. “All three anode samples showed higher lithium-ion capacity than current graphite or silicon-carbon anodes used in Li-ion batteries as well as superior conductivity. The silicon-MXene anodes had on the order of 100 to 1,000 times higher conductivity than conventional silicon anodes.”

Good for Mass Production

“The continuous network of MXene nanosheets not only provides sufficient electrical conductivity and free space for accommodating the volume change but also well resolves the mechanical instability of Si,” according to the researchers. “Therefore, the combination of viscous MXene ink and high-capacity Si offers a powerful technique to construct advanced nanostructures with exceptional performance.” The process of slurry-casting MXene-silicon anodes is scalable for mass production of anodes of any size, which means they could make their way into batteries that power just about any of our devices.”

Researchers found that slurry casting prevented the silicon anode from expanding to its breaking point, something other researchers have attempted for the last decade. Unrestrained, silicon can expand as much as 300 percent, which can cause it to break and make the battery malfunction. Excellent mechanical strength in the silicon-MXene anodes holps hold things together. The anodes “are quite durable up to 450 microns thickness.”

This could expand the charge-to-charge life of cell phones and electric cars by as much as 40 percent, according to researchers from Drexel and Trinity College in Ireland. “Silicon anodes are projected to replace graphite anodes in Li-ion batteries with a huge impact on the amount of energy stored,” said Yury Gogotsi, PhD, Distinguished University and Bach Professor in Drexel’s College of Engineering and director of the A.J. Drexel Nanomaterials Institute in the Department of Materials Science and Engineering, who was a co-author of the research. “We’ve discovered adding MXene materials to the silicon anodes can stabilize them enough to actually be used in batteries.”

You can see Dr. Gogotsi’s recent presentation in Spain below.

Researchers found that slurry casting prevented the silicon anode from expanding to its breaking point, something other researchers have attempted for the last decade. Unrestrained, silicon can expand as much as 300 percent, which can cause it to break and make the battery malfunction. Excellent mechanical strength in the silicon-MXene anodes holps hold things together. The anodes “are quite durable up to 450 microns thickness.”

This could expand the charge-to-charge life of cell phones and electric cars by as much as 40 percent, according to researchers from Drexel and Trinity College in Ireland. “Silicon anodes are projected to replace graphite anodes in Li-ion batteries with a huge impact on the amount of energy stored,” said Dr. Gogotsi, who was a co-author of the research. “We’ve discovered adding MXene materials to the silicon anodes can stabilize them enough to actually be used in batteries.” Lead author Chuanfang (John) Zhang from Trinity College, Ireland submitted the paper, “High capacity silicon anodes enabled by MXene viscous aqueous ink,” to Nature Communications, where it was published on February 20, 2019.