Dipl. Ing. Calin Gologan, an exhibitor and presenter at this year’s E-Flight Expo at Friedrichshafen, will be at the fourth annual Electric Aircraft Symposium, discussing the design and technology he hopes will imbue the winning entry in next year’s Green Flight Challenge. He notes that the GFC, “the world’s largest prize…awarded in general aviation,” was a major incentive in his pressing forward with an environmentally conscientious design.

His Elektra One is part his PC-Aero’s ambitious campaign to fly three different electric aircraft in the next few years, the single-seat “One,” two-seat “Two,”, and most ambitiously, a four-seat “Four.”

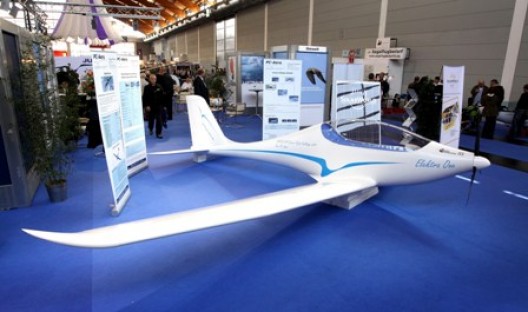

With at least the shell of Elektra One at the Expo, Gologan is making good progress toward completion of his GFC machine, the prototype for the first of a line of production aircraft.

Gologan’s goals are enunciated in his PC-Aero web site. “The Elektra One is environmentally friendly, because it flies without CO2 emissions. It is light and has a high end aerodynamics. Integrated are modern technologies: batteries, electric motors, solar cells and lightest fiber composite structures. In this electric airplane the latest scientific ‘green’ findings are integrated.”

With a 90 kilogram (208 pound) empty weight, including motor, for its 27 foot wingspan, 21 horsepower, and a lightweight battery pack, the One will top out at no more than 120 kilograms empty to meet limits for the new German ultralight class. This will allow pilots to fly without a medical, a key part in making these new machines available to a broader public.

In common with all airplanes in the Elektra family, the One has a light carbon fiber structure, a sailplane-like 26:1 lift to drag ratio, and a three-hour flight endurance. This is a significant challenge for a battery pack that can weigh no more 30 kilograms (66 pounds) to keep the empty weight within UL limits. Future refinements may include solar cells in the slender wings for range extension, and some views suggest retractable landing gear.

The product displayed at Friedrichshafen is beautiful, and we look forward to further developments.

Comments 14

Please do not take this post wrong; I suport efforts for electric flight as the vehicle as a whole has the potential to become more efficient and potentially have the ability to become more reliable than internal combustion engines. Mind you I said potential, but as for being a green product, I think that many of these systems are getting a pass for being green without considering the entire power system.

Batteries and liquid fuels differ in that the fuel is directly converted into energy via combustion in the engine attached to the plane. This may seem like an obvious statement, but here is where the major difference is to be found. With batteries, most methods of providing power come from combustion. This may range from coal to natural gas. Yes there are other forms of power generation, but they do not tend to represent the majority of power generation, and of course there can be no agreement as to which of these methods is green (think about it nuclear is now proclaimed as a green energy source, but look at how it was viewed in the 70’s, or how hydro was stopped due to environmental concerns). To charge a battery, we must use a process that is in the efficiency range only slightly higher than a car’s ic engine, let’s say for argument that it is 50% efficient. There are now line losses in transmitting that power to the charging station. We will say that is 90% efficient, our overall system is now at 45%. We now need to convert that power from AC voltage to DC voltage to charge the batteries. Once again let’s say that this is 90% efficient, we are down to 41%. Now that the batteries are charged, and not taking into account that batteries naturally discharge if they are left to on their own, we now need to run a motor that is for the sake of the argument 90% efficient. We are down to a system that has an overall efficiency of 36% efficient, or right in the range of good combustion engine and we are still burning fuels to get the entire process done.

The gains are not to be found in the efficiency of the electric motor, but in the potential to have better aerodynamics: much lower cooling losses, better form drag due to a better cowling, and slightly improved propeller performance due to less blockage after the propeller. There are also gains to be made in the system complexity as the replaceable part count will go down (battery, charging circuit, speed controller, and motor) though some may argue that electronics only add complexity.

The only drawback that still remains is of course the weight, size, and other complications of the battery. There are still issues of the fact that the battery does not have the weight to energy level of combustible fuels, and their lifespan which will add to the over cost of the price per energy released. This combined with the need to establish a program to recover the battery to remain with the environmentally friendly mantra that we are trying to follow.

To sum it all up, I am happy to see the advancements in the electric power field. I remember when electric powered model airplanes were a joke, and now they are more of the norm than the exception. I do think that there are great potentials to be achieved with electric power, but to call it a green technology is somewhat of a naïve viewpoint. The vehicle itself does not produce emissions, but to charge the battery there are emissions produced. If we can agree to call nuclear a green energy source, and replace the power generation with it and systems such as solar, geothermal and a few other debated green energy sources, then and only then can we say that electric powered vehicles are part of a much larger system that reduces emissions and contribute to what have been established as green goals.

Adam

Author

Adam:

Thank you for a very thorough and well thought out response. The question of transmission loss, overall costs of operation, and total efficiency of the system have been addressed by CAFE, particularly in last year’s presentations at EAS III. Various schemes, including solar-cell hangar roofs, are being developed that may address at least part of the issue. Greg Cole of Windward Performance shows a solar roof and wind turbines powering a hangar and charging an electric airplane sitting next to the hangar. As suggested in an article last year in this blog, we do – to be honest in our assessments of what we’re doing to our planet – need to to perform a life cycle analysis of the true costs of each step of creating, using, and disposing of our devices.

Blaise Pascal told us to be skeptical of the things we believe most, and St. Paul wanted us to test all things, and hold fast that which is good. You response opens what I hope will be a lively and informative debate.

Adam :

You wrote : “The (electric) vehicle itself does not produce emissions”…

That is true about flying, but this vehicle has first to be built . If this aircraft needs to be totally carbon fiber built for saving weight and performances reasons, there is a huge amount of energy (that is to say emissions) included in the airframe at the start, anyway the aircraft flies or not. Maybe the same for batteries; furthermore their reduced life time darkens the green count.

(Editor’s note: Paul Lucas, with Serge Pennec, designed and built Dieselis, a light aircraft that flies behind an Opel diesel engine. Their lightweight wooden construction and home-made reduction gear system contributed to the good performance of the plane and its low cost – about $7,000. One might quibble, though with M. Lucas’s view of carbon fiber and battery issues. Carbon fiber can be recycled, as can lithium and other materials in modern batteries. How much this will contribute to long-term and overall real costs is still to be determined, and should be part of an ongoing investigation and dialogue.)

Author

Dear M. Lucas:

It is an honor to have a response from you. We have been starting a discussion of the actual costs of creating these new materials and power systems. You and M. Pennec saved by using a “recycled” engine, which in the case of a Diesel, is a good thing, since they tend to have a long life. I have tried to interest others in a contest to see who could build the best $10,000 airplane. I believe that if you trade time for money, you can accomplish some wonderful things inexpensively. Witness your accomplishment – a quite magnificent one.

Thank you again for your interest.

By the way, I am featuring Dieselis in my talk this year at the Electric Aircraft Symposium. If one replaced the heavy diesel engine with a light motor and a substantial battery package, one could have a successful electric craft.

Dean Sigler

Paul,

Perhaps I am reading your comment incorrectly (the unfortunate byproduct of the internet) but you actually seem to be adding even more to the argument that I was trying to put forth, which was two fold: first everything needs to be looked at as a system, and not from a “marketing” perspective, and second that no one can even agree what “green” means and consequently has only become a term for marketing and politicians.

So as to be understood, I am not what you would call an environmentalist, nor a “green” advocate. I am an engineer. As an engineer one tries to make things better and do it more efficiently as this leads to better performance. There are obviously differing areas in which one might try to improve a concept, and in the end everything is a compromise. I find it unfortunate that this world has become so polarized to not recognize this plain fact that there is still no such thing as a free lunch.

That being said, I am also not an advocate of being dirty and wasteful for the sake of doing so. There is a complex balance that needs to be maintained as energy went into past generation systems to have them produced, and to throw them away for the sake of getting something that is more efficient (energy efficiency) may in the end cause more money to be spent and the same amount of overall energy to be consumed for both systems (the original and the replacement) as for if you were to have kept the original system longer and replaced it at its end of life or close to that point.

To deal with your argument more specifically of building materials, this is a given equal trade. You have plane A, and plane B. Both are built of some material which require the consumption of resources to manufacture. What are the actual amounts of resources for a particular amount of material compared to the operating resources of the product life cycle? I do not know, but I would be willing to bet that the resource cost of the materials are negligible compared to the operating resources. I freely admit that this is a semieducated guess, please do not quote it as fact, and feel free to prove or disprove it.

Adam

Aeroengineer,

It is wrong to bring the energy production process into the efficiency equation for the aircraft. That is a matter for upstream technologies. It should be assumed that the energy to charge the batteries comes 100% from solar energy because that is entirely probable. On the energy conversion efficiency my technolgy partner is developing circuitry that promises 98% efficiency for both solar voltages to line energy and battery energy to managed motor energy. Apart from all of the obvious advantages of electriccally powered planes it is important to register that the on board energy conversion does not suffer from the thermal inefficiencies of internal combustion engines (35% efficiency wasting 65% of the available energy). This offers some measure of compensation for the lower energy density of the fuel. All of the technologies are heading in the same direction, and this is so exciting.

Bill,

I am not sure if this post will get posted, I still have one more awaiting moderation, but as an engineer I feel that we cannot pick and choose how we evaluate new proposals in the manner that you propose. It is important to analyze a situation in which the most common usage method should be looked at first, and then at the minor uses later. The reason being is that you cannot control the other variables with confidence.

The standard user today would plug the electric battery into a wall charger as this is the cheapest (initial investment) method to get the desired result. Because of this we need to, as engineers, stop looking with tunnel vision to achieve great results. We tend to have the if we build it they will come syndrome. Unfortunately we build only a small portion of the puzzle and the rest of the pieces never get implemented.

As for solar, is it possible to do? Yes. Is the cost of installing such a system high? Yes, perhaps as much as the aircraft. Are there limitations? Yes, the rate of charge is low, cloudy areas, night times, and what happens when I am flying cross country? The cross country limitation alone could hamper the effort as charging a battery this large will take hours even on a “standard” wall connection, let alone solar power. If there was a solar installation that could provide the voltage and amperage requirements, it would have to be large and therefore more likely to have to be funded at government level for initial infrastructure establishment and growth.

To sum this all up, we need to take a broader view of how our new and exciting technology fits in as a system to truly understand if we are making an incremental improvement or a step change. We must be realistic about its method of use and not just give the most optimistic case. Remember the masses will not use the most optimistic engineering case unless it is somehow optimistic for them (read here, costs less). Lastly, and unfortunately, unless we can overcome regulatory hurdles and provide a true product that is as safe or safer than the product it is intended to replace this will remain in prototype stage. Do I think that is is possible to have adoption of general aviation electric aircraft, yes. Do I think that it will be common place in the next 20 years, I do not. Do I think that it can become accepted and eventually get certification through the FAA yes, though at great expense to the pioneers.

Adam

Aeroenginer1 has some points in the first comment but I cannot totally agree to the calculations as they only take in to account, as far as I can see, the losses in efficiency on the electric system and not in the losses in the system that produces gasoline for the combustion engine airplanes. The refinery of oil in to gas is in itself a wasteful system and then one has to take in account the delivery system that transports first the oil to the refinery usually quite a long way, and then there is also the transport of the refined product, in this case gasoline to the airport. Taking this in account would probably make it seem like a totally different matter as the already low efficiency of combustion engines would be even more reduced.

There is also the matter of charging times batteries, and then I don´t think about the time it takes but the hour of the day, or rather night. During the night there is, at least where I live, an enormous overcapacity in the electricity production system that means that charging things like airplane would not make any direct impact on the emissions from power plants as they are running way too high anyway as they cannot be easily adjusted for short periods of time. The electricity is also extremely cheap during the night due to the low demand.

The sort of power plant also make a big difference on the emissions from the airplane, when all things are counted in, this is of course differs from country to country and where I live only a small percentage of the electricity comes from gas, coal and oil power plant and that of course makes the electric airplane a more interesting alternative. There is also a possibility to choose power source for the electricity you buy, or to be exact, one can choose to only buy electricity from green power plants, water and wind in reality.

I’ve been driving electric autos to work for over 10 years. My wife also drives electric to work daily. Yes the autos both run highway speeds. Everyone is so focused on “it won’t work” that the progress is slowed. First coal fired is still cleaner than ICE power. Second, I have a solar/wind array where I get the power for the cars. An electric powered “Sunday flyer” could be powered by electric which one gets from their own array. Charging is slow but if you only fly like most private pilots maybe twice a month or once a week, the battery is charged.

Stop thinking like Exxon/Mobil, BP, and Shell want you to think.

(Editor’s Note: one of the things that retards progress is sticking with the status quo. We each can empower (!) ourselves, as Mr. Brecher has done, and achieve a future that looks the way we want it to.)

Aeroengineer1…

If I understand your first argument you are concerned that an electric plane is called green due to the original power coming from non-green sources. Even after you showed that the use of the non-green sources [is] less in the electric plane compared to an equivalent internal combustion plane.

The one thing the electric plane can do is get more green over its life. As the mix of energy changes from fossil fuel (coal, oil etc) to green power (solar, wind, wave) then this plane becomes more clean/green. NO internal combustion plane can do that.

Appreciating the time and effort you put into your site and in depth information you present. It’s nice to come across a blog every once in a while that isn’t the same old rehashed information. Wonderful read! I’ve bookmarked your site and I’m including your RSS feeds to my Google account.

(Editor’s Note: Thank you!)

Aeroengineer: Your efficiency assumption for battery charging is way off.

A gallon of gas contains about 34 kWh kWh of energy. The average electric car can travel well over 100 miles on that energy. I’m not so sure about an electric plane. It also takes 6 kWh of electricity just to refine a gallon of gas. Then there is the energy wasted transporting the gas. Wars have been and are being fought over oil. Oil spills destroy entire ecosystems. I’m all for freeing us from oil.

The Elektra One is marketed with a solar trailer enabling it to be flown for free. No gas-powered motor glider can match the cost of ownership of a solar powered electric glider.

I’m very late to this discussion (too late?) Anyway, I have been working with energy production on an R&D level my entire adult life, and I have been flying and building airplanes (RC and experimental) even longer. I am still doing both.

Electric airplanes will be the next revolution in aerospace technology, but not for any of the reasons you propose. The reason you propose is the political push, but ultimately people themselves will eventually *choose* to go electric. The reasons are less noise, simple construction overall (less vibration), no fumes, better performance overall, virtually no maintenance, etc. The electric choice is simply a much better choice overall for *practical* as well as performance reasons. What is holding this revolution back is of course battery technology. With current battery technology it is impossible to achieve the usual mission the typical GA airplane is filling – endurance mostly, but also the fact that charging takes too much time. Cost of battery packages is also an issue, but mostly due to lack of standardization: it is not a technological problem.

Let’s look at RC airplanes. How are the endurance and charging problem solved? Endurance is not an issue today, the current battery technology is good enough for a typical RC flight. The charging problem still exists, and the solution is replaceable battery packages. When one is used, one or two others are charging, or they are pre-charged. And of course, standardization of batteries, chargers, contactors, engine technology, engine controllers etc. has made all this affordable for everyone.

At exactly what level is the electrical choice today, and is this level good enough for *some* typical GA missions? Look at the Tesla sport car, that is the current level regarding performance. This level of performance can today, with virtually no modifications, be used in aerobatics (short flights, lots of power, more than current level). It can, and is, used for gliders replacing two stroke engines to sustain and for self launching. It can be used for glider tugs, and achieve MUCH better performance than current alternatives. It can be used for trainer aircraft (short duration of flight close to the airport). The reason the electrical choice isn’t utilized in all these areas are purely practical ones, there are *no* technological obstacles there. The practical problems will only be solved when people start solving them, and that is only done by doing. When doing, an industry will automatically emerge, standardization will emerge, with good solutions for battery packages, charging, easy replacement of battery packages.

PC Aero is one pioneer in this area, and more are coming. Is it “green”? My answer is undoubtedly YES. It is “greener” than any fossil fuel alternative today, and will only become even “greener” in the future when solar power grows on an international level and battery technology gets better. A political push is good, necessary even, but already today the technology is developed to such a degree that several areas of GA will achieve much better performance by going electric than they are doing today. It is the practicalities and lack of industry that is holding it back, we only need more pioneers: more people have to start doing.

(Editor’s Note: We are unaware of “pushing” a political solution to battery or other issues involving electric or green flight. Most of the blog extols the efforts of individuals and groups – quite often on their own dime – who struggle daily with making batteries more powerful, longer lasting, and more reliable; or who put untold dollars and euros into developing aircraft that may or may not find a market willing to pick up the early adapter high costs. Note the corpses of electric automotive companies strewn along the roadway, despite many having gained government funding, both here and in Europe.

Modelers have the advantage of fielding a small vehicle, being their own logistics center and supply chain and being able to afford replacements when all goes wrong. People like Randall Fishman, Eric Raymond, Mark Bierele, Dale Kramer, and Brian Carpenter (among many others) have risked their own fiscal and physical well-being designing, building, testing and promoting their pioneering efforts. Don’t deny them credit.

Likewise, some of the best minds in the world are struggling with getting anodes, cathodes and electrolytes right. The recent Electric Aircraft Symposium saw some of the most outstanding efforts in the academic and commercial world to make all that you propose a reality. Please understand that none of this is as easy as it looks – and there are days when it looks pretty daunting. We will have success and maybe sooner than we think or hope.

Many are achieving success within the limitations you note. Anne Lavrand has helped power several record-setting airplanes with simple brushed motors, for instance, and Eric Raymond crossed the U. S. on old-school solar power 23 years before Solar Impulse – with lots of big money backers – began its attempt. The garage inventors are doing what they can, and combining their efforts and skills with the brain trusts available will give us some extraordinary breakthroughs.)

I didn’t mean to deny anyone credit. Quite the opposite actually, there are thousands of excellent engineers and scientists spending their careers on electrifying transport, and succeeding at it. I was only trying to point out the different forces working. Electrification of transportation is definitely something that receives a political “push”in the form of fundings for instance. Even though 99% of this is about electric automobiles, the core technology (battery, motor, controller, charger) can with no, or minimal modifications be used for flight. From this year and next year, every major car brand in Europe has one or several electric versions of their ordinary models. This is ordinary cars with equal HP as their gasoline/diesel siblings, like the BMW ActiveE at 170 HP. The range is only about 200 km, enough for everyday use, but not exactly something to use for long trips. Electric cars still have a long way to go in terms of range, but the days where electric cars were odd colored plastic boxes with 10HP are definitely gone.

Modern battery technology is something that is way beyond what even the smartest individual is able to create in their basement. The production processes is far too complex and costly for anyone but large companies. To get the price down, mass production on a large scale is required, similar to IC, CPUs etc. This complexity will only increase, because to achieve higher power density, the technology is headed into the nano world.

For RC the core battery technology is from gadgets like mobile phones, LiPo typically. The motors are derived from space technology and computers (hard disks, CD drives) and so are the controllers. It is only the high power chargers that are special made. The point is that those technologies have revolutionized electric RC, because an industry has grown around it to such an extent that the performance is equal or better than the alternative, at a lower price, no noise, more practical. New branches has emerged even, like indoor flying for instance. But, without brushless motors and (affordable) LiPo, electric RC would still only be slow flying gliders or heavy trainers, a small niche for a few enthusiasts.

A similar thing will eventually happen to flight. Today more and more people go for electric cars, not because of ideology, but because of basic practicalities. The newest electric cars looks, behaves and drives like any other car. Instead of a Golf TSi, you get a Golf E, the only difference is the engine and much lower fuel and maintenance cost (if you can live with the limited range). The VWs can even be charged in only 15 minutes. With better battery technology, range will increase. With more competition and larger production, prices will decrease and standardizations will emerge. Infrastructures for recharging will be developed and so on. All these benefits (performance and cost) will also make it to flight. And then, when people start using electric airplanes, an industry will emerge there as well.