We see a great deal about wearable energy-generating fabrics, garments that will help keep the wearer warm, or cool, or visible because of built-in piezo-electric generators in the makeup of the fabric. Several researchers are taking this to the next level, creating new warps and woofs of materials that will create energy from a greater range of energy inputs.

Elias Siores and the University of Bolton

In 2011, Professor Elias Siores and associates at the University of Bolton in the UK created a flexible fiber that could harvest energy from movement and light. Siores said it was flexible enough to be woven into “a sail, window curtain or tent and generate power”. The material was recognized as a major innovation at the 2011 Energy Innovation Awards in Manchester.

Professor Elias Siores with a sample of his energetic fiber

In a 2013 paper, the team, led by described devising a “smart fabric.” “A smart material is one that shows extraordinary response when subjected to a stimulus. Piezoelectric materials are considered as smart materials because of their ability to generate electricity against the stimulus which is mechanical strain or vibration. This property of piezoelectric materials is known as direct piezoelectric effect. The reverse effect is also possible in that this material undergoes a slight deformation in shape when a small electrical field is applied.”

Coming up with a flexible fabric allow knitting or weaving it into fabric for clothing, cases for personal gadgets, and even sails, window curtains or tents, which could charge batteries on boats or portable electronics that could make camping more like glamping. Siores had noted “renewable energy sources such as sunlight, wind and rain are not always available at the same time in the same location,” making this a more versatile material that could operate under a variety of circumstances. A detailed paper on the team’s work can be found here.

Jayan Thomas and the University of Central Florida

Jayan Thomas and fellow researchers at the University of Central Florida added to the happy combination of energy-harvesting threads and added energy storage, with cotton, copper, perovskite solar collector and capacitor energy storage fibers cleverly woven into something wearable (and maybe even fashionable).

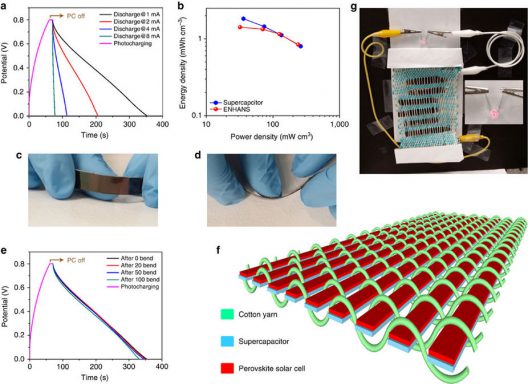

Simple loom for hand weaving energy collecting, storing fabric at UCF

We all dream of emulating our film heroes, but Professor Thomas took it to the next level, having seen Back to the Future. “That movie was the motivation,” …Thomas, a nanotechnology scientist at the University of Central Florida’s NanoScience Technology Center, said of the film released in 1989. “If you can develop self-charging clothes or textiles, you can realize those cinematic fantasies – that’s the cool thing.”

The team’s paper in the journal Nature Communications explains how the woven materials collect sunlight, the flexed motion of the wearer, and store that energy for delayed use. Thomas saw this as a way to help soldiers in the field, who often carry 30 pounds of batteries for the many communication and navigation devices a modern infantry man or woman must pack besides weaponry and ammunition.

The paper details how the researchers managed to meld the elements in their cloth. “In this study, we report an all-solid-state, energy harvesting and storing (ENHANS) ribbon that integrates a perovskite solar cell (PSC) on top of a symmetric supercapacitor (SSC) via a copper (Cu) ribbon which works as a shared electrode for direct charge transfer. A highly flexible, thin, sandwich PSC with >10% conversion efficiency is developed by a solvent-assisted perovskite growth technique. The sandwich-type device configuration provides better protection for the solar cell against environmental effects due to an unexposed perovskite layer to the atmosphere. The Cu ribbon not only serves as an electron-collecting electrode for the solar cell but also as a substrate for generating copper hydroxide nanotubes (CuOHNT) for developing the supercapacitor.”

(a) Charge–discharge profile of the ENHANS ribbon. The solar side of ENHANS ribbon has been charged with the solar simulator for 1 min and discharged with electrochemical workstation at different current densities after 10 s photocharging (PC) off; (b) Ragone plots of an independent supercapacitor and an ENHANS ribbon to compare the energy density and power density at different charging–discharging rate (1, 2, 4 and 8 mA cm−2 current density); (c,d) photograph of the ENHANS ribbon being bent at different angles; (e) charge–discharge profile of the ENHANS ribbon after a different bending cycles (the ENHANS ribbon has been photocharged for 1 min, and then removed from light 10 s before discharge); (f) schematic illustration of the ENHANS ribbon after weaving with the cotton yarn to make a portable lightweight cloth and (g) ENHANS ribbons weaved with cotton thread to demonstrate the working of the lightweight fabric. The photograph shows the charge deliverability of weaved matrix as a result of one minute photocharging.

Zhong Lin Wang and the Georgia Institute of Technology

Zhong Lin Wang at the Georgia Institute of Technology, along with a phalanx of scientists in colleges and universities throughout China, devised a fabric described in their paper, “Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors,” was published in the October 26, 2016 edition of Science Advances.

Sample of Georgia Tech energy cloth

Taking the manufacture of this material beyond small samples, Wang explains, “The backbone of the textile is made of commonly-used polymer materials that are inexpensive to make and environmentally friendly. The electrodes are also made through a low cost process, which makes it possible to use large-scale manufacturing.”

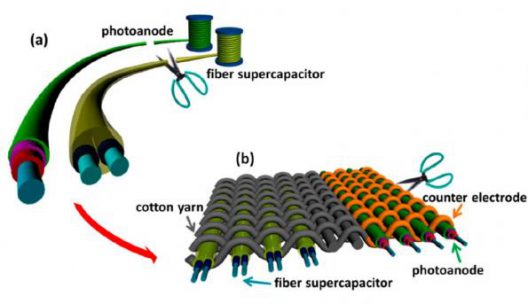

Wenjie Mai and Researchers in China and Singapore

Researchers at Jinan University and Chongqing University in China, and Nanyang Technological University in Singapore took a similar approach, creating threads which store energy from piezoelectric reactions and solar energy. “The ‘threads’ (fiber electrodes) featuring tailorability and knittability can be large-scale fabricated and then woven into energy textiles. The fiber supercapacitor with merits of tailorability, ultrafast charging capability, and ultrahigh bending-resistance is used as the energy storage module, while an all-solid dye-sensitized solar cell textile is used as the solar energy harvesting module. Our textile sample can be fully charged to 1.2 V in 17 s by self-harvesting solar energy and fully discharged in 78 s at a discharge current density of 0.1 mA.”

Fiber supercapacitors and photoanodes woven together with cotton and counteranode fibers. Things are connected with conductors at fiber ends

Wenjie Mai, Department Chair and Professor in the department of physics at Jinan University (China) explains how these fibers are connected to produce a current. “We simply use metal wires to connect all these fibers at their extremities” This may not look perfect, it was good enough to show the idea on a working prototype.

An Ending with a Twist

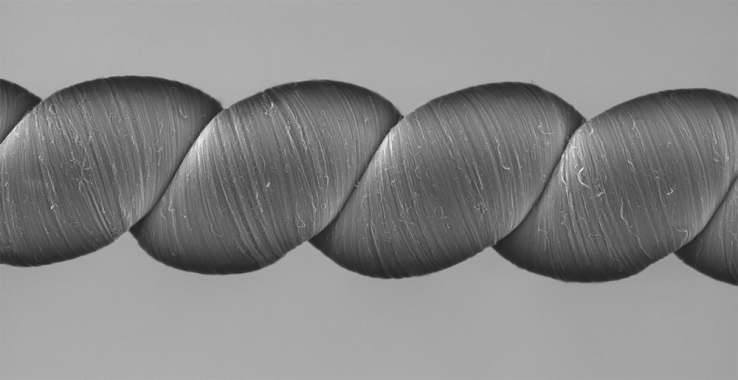

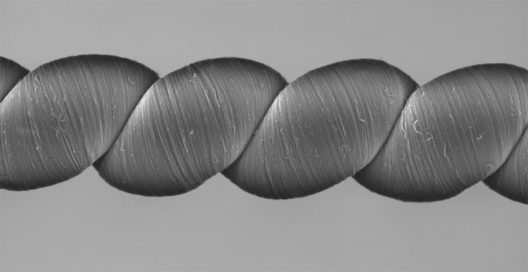

Twistron sounds like a commercially-viable product already, and the potential for this twisted carbon nanotube actually might exceed the performance of some lithium batteries. Developed by researchers at the Alan G. MacDiarmid NanoTech Institute, University of Texas at Dallas; the Center for Self-Powered Actuation, Department of Biomedical Engineering, Hanyang University, Seoul; the Department of Materials Science and Engineering, University of Texas at Dallas, and numerous other organizations, Twistron takes a literal twisting of the yarn-like material to produce energy. The teams’ paper, “Harvesting electrical energy from carbon nanotube yarn twist,” appeared in the August 25, 2017 edition of the journal Science.

Twistron yarn comes close to rivaling lithium cells in energy density

According to Green Optimistic.com, “A twisted yarn that is stretched 30 times per second can generate a power of 250 watts per kilogram of the yarn. This rate is over a hundred times higher than other energy-harvesting fabric yet developed.” (And similar in energy density to good-quality lithium cells.)

How these fabrics might be moved from fashion to structural use in aircraft is open to question, but the widespread research, of which only a handful of possibilities could be described here, show progress and potential. Consider the idea of older, fabric-covered airplanes that could be restored and electrified, gaining a new lease on life after all the antique Continentals and Lycomings are reduced to scrap. Or think of hang gliders and ultralights that might be at least partially powered by sunlight and the flexing of their fabric sails.