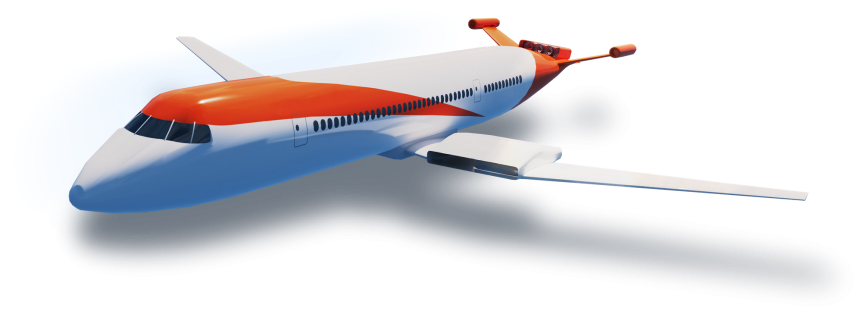

Twelve years ago, your editor gave his first talk at an electric aircraft symposium. Dr. Brien Seeley asked that he include all motors up to 100 kilowatts in his talk – at that time a rarity. Designers often had to “gang” small motors to drive a single propeller to obtain the necessary power. Now, Wright Electric has announced its plans to develop motors (and associated equipment) in the 500 kilowatt to 20 megawatt range. Motors of those sizes are still under development, but Wright claims to have tested and demonstrated “a megawatt-class, high performance inverter,” according to Green Car Congress. Jeff Engler is getting recognized for his vision. Here he give his virtual elevator speech at the Davos, World Economic Forum. His positive and yet measured approach seems to gain acceptance for that vision. Demonstrated Performance? Aiming for some audacious levels of performance, Wright’s inverter could hit these metrics: “99.5% efficiency –a 6x improvement in heat loss over current in-production …

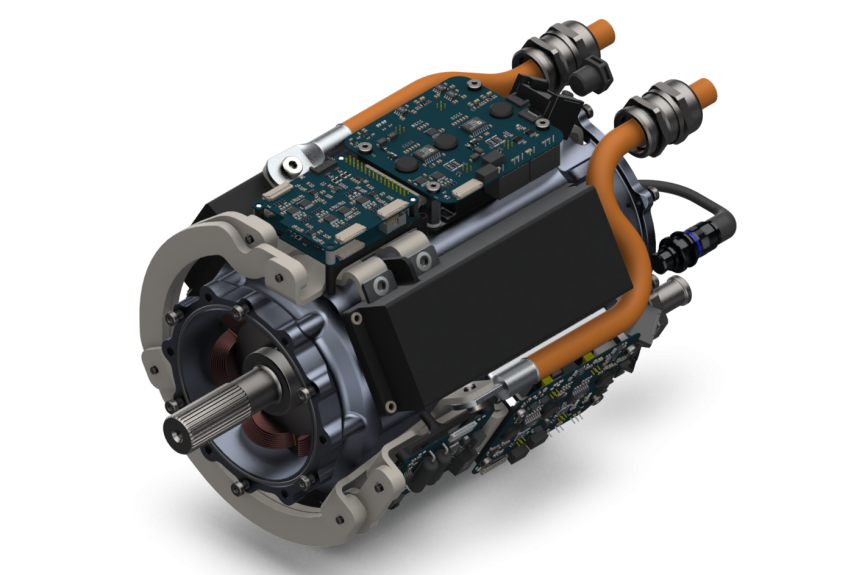

H3X – A Motor with High Power Density

H3X, a motor company started by three University of Madison, Wisconsin graduates, promotes its integrated motor/inverter power plant as “the next step in the evolution of electric propulsion technology.” With Their HPDM-250’s 13-kilowatt-per-kilogram continuous power ability, it meets ARPA-E’s (Advanced Research Projects Agency–Energy’s) criteria for powering large, 737-type aircraft. Electronics Weekly reports, “ARPA-E has determined that for a Boeing 737 to complete a typical five hour flight, the propulsion system must be >12 kW/kg continuous.” H3X adds, “These specifications are estimates based on electromagnetic thermal and structural simulations. Data from dynamometer will be available Q2 2021.” Their motor is roughly twice as power dense as MagniX motors of similar power, according to H3X. Weight reduction is an intrinsic part of aircraft design. In the days of internal combustion engines (still very much with us), conventional wisdom held that reducing power plant weight by one pound could help take two pounds off the airframe. Even today, ICE engines generally produce only …

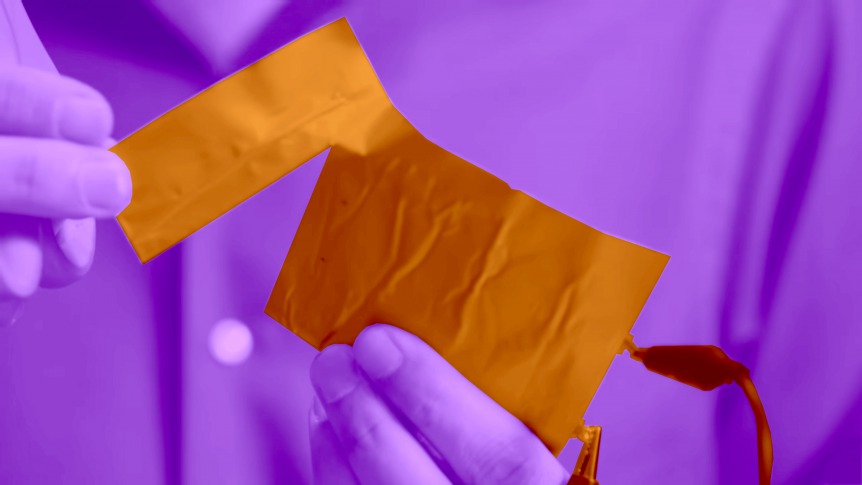

Rechargeable Alkaline Batteries Seem Inherently Safe

Ionic Materials, A Woburn, Massachusetts-based company, claims to have crafted a battery with an alkaline solid-state electrolyte that successfully resists punctures, cuts and other injuries. It doesn’t burst into flames like many lithium-based batteries. In demonstrations, the battery survives 9mm and 25-caliber bullets. A more personal attack takes place with a screwdriver and paper cutter. When a “conventional” lithium battery suffers such assaults, the liquid electrolyte leaks and sometimes causes a short circuit, channeling all the energy into the flammable liquid. Remember recent hoverboard and airline incidents and a spate of smart phone meltdowns to make you more than a little nervous about the cell phone in your pocket or tablet nearby. Such thermal runaways on a small airplane are absolutely unacceptable. Ionic Materials claims to have overcome this issue and promises performance improvements over existing chemistries. ”We have created a solid polymer that conducts ions at room temperature, a world first. This new material produces immediate benefits for battery …