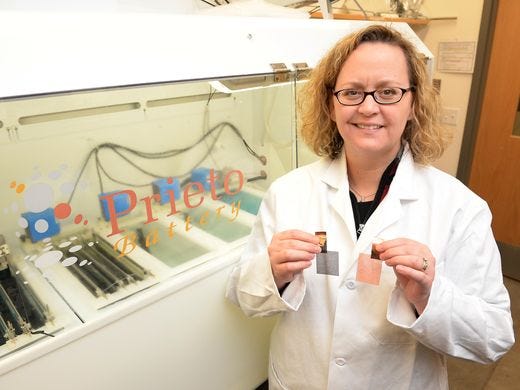

Dr. Amy Prieto created her namesake battery a decade ago, and has been seeking funding and other support for its development ever since. It gained such funding from Stanley Ventures in 2016. Prieto Battery, as reported by GreenCarCongress.com then, is, “A company commercializing a 3D Lithium-ion battery technology (earlier post), announced a strategic investment from Stanley Ventures, the venture arm of Stanley Black & Decker, a world-leading provider of tools and storage, commercial electronic security and engineered fastening systems.” Possibly more important that money, Dr. Prieto’s battery recently received third-party validation of its claimed safety and performance attributes from Energy Assurance, LLC. GreenCarCongress reports, “Specifically, Prieto had a group of fully assembled batteries containing their proprietary 3D anode tested against an array of UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) standards for Li-ion chemistry. All of Prieto’s batteries had 100% success rate with zero failures.” Dr. Prieto seems happy with these results, stating, “These results validate the science and manufacturing …

The 17X Aluminum-Air Battery?

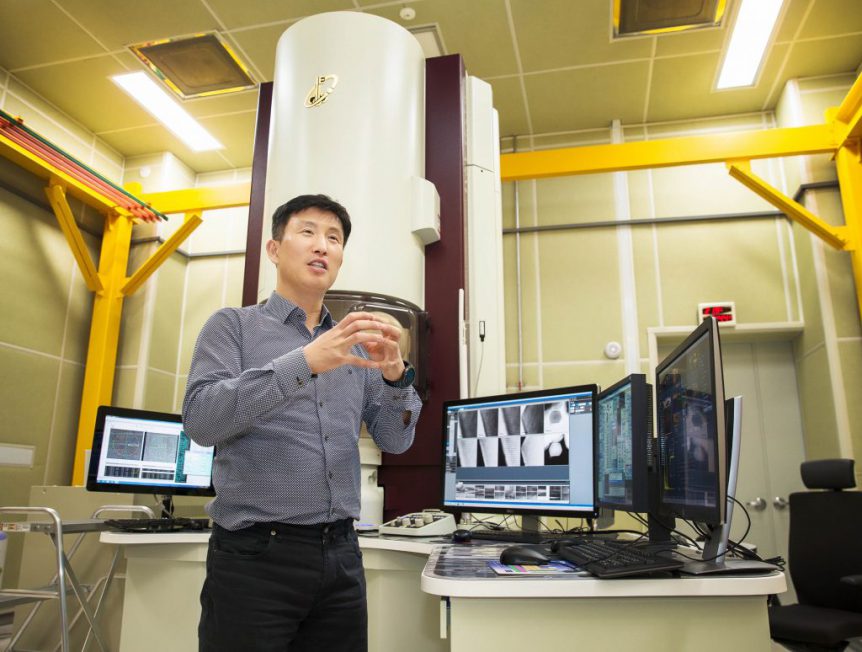

Jaephil Cho has a surprise for us – an aluminum-air battery that is potentially (no pun intended) more energetic than gasoline. Director of the Research Center for Innovative Battery Technologies and Professor in the School of Energy and Chemical Engineering, at Ulsan National Institute of Science and Technology (UNIST), Cho and his students have released over 350 papers, including one titled, “Seed-mediated atomic-scale reconstruction of silver manganate nanoplates for oxygen reduction towards high-energy aluminum-air flow batteries.” While such titles might not get him on the NY Times best-seller list, Cho is widely respected, UNIST reporting he has been named to the 2017 Highly Cited Researchers List in materials science, a second such honor for him. Professor Cho’ Surprise Professor Cho’s paper (in full) describes the aluminum flow battery he and his team developed. According to the UNIST News Center, “…Compared to the existing lithium-ion batteries (LIBs), the new battery outperforms the others in terms of higher energy density, lower cost, …

Raising Cane at the Battery Works

What if a battery could be made with higher energy and power densities than those currently available, while exploiting a natural material that’s both abundant, recyclable and inexpensive? Last year, the blog reported on Y. H. Percival Zhang’s work with xylose, a sugar found in most plants, to make hydrogen that could be used in fuel cells. Dr. Zhang, with a Ph.D. in chemical engineering and biotechnology from Dartmouth University, draws on his unique pair of specialties to inspire his forays into developing novel ways of extracting energy from natural sources. His latest effort is a battery that runs on maltodextrin, a polysaccharide made from the partial hydrolysis of starch. That starch can be derived from almost any type of plant, a ubiquitous and non-food-based source. This makes for a tidy life cycle, extracting the raw materials from nature and being able at the end of the battery’s long and refillable run to return them to nature without fear of …

SolidEnergy Teams with A123 for High Energy Density Battery

Take two Massachusetts Institute of Technology (MIT) business incubator realizations, mix their strengths and watch for the potential breakthroughs that could come in the form of high-energy-density batteries. According to its web site, “SolidEnergy is developing a safe, high energy density, and wide temperature capable rechargeable battery that has the potential to transform the consumer electronics, electric vehicle, and downhole exploration (as in well drilling) industries. The core technology is called a Solid Polymer Ionic Liquid (SPIL) lithium metal battery.” Founded in 2012, “one of the toughest years in the battery industry,” SolidEnergy’s “…objective is to develop an insanely great next generation battery and commercialize it in the fastest and most efficient way.” This decidedly brash approach needs a steadying hand at the wheel, which is where its partnership with A123 Systems comes into play. A123’s first collaboration under its expanded research and development model combines SolidEnergy’s SPIL technology with “the mature cell design and prototyping capabilities of A123.” This would help …

Vanadium Oxide/Lithium Batteries Offer Promise of High Power, Long Life

Henry Ford once brought a French metallurgist to Detroit, part of his plan to build cars with lighter, stronger steel. Vanadium, which the French used in their automobiles, offered him the chance to make the Model T lighter and stronger, and its part in the car’s alloyed steel gave the Model T the longevity which followed it through one of the longest production runs in history. Now battery researchers are looking at another quality of this mineral, its ability to form a superior cathode for batteries that “could supply both high energy density and significant power density. Combined with graphene, the wonder material du jour, vanadium oxide (VO2) could couple longevity echoing the Model T’s with charge and discharge rapidity similar to a supercapacitors. Materials scientist Pulickel Ajayan at Rice University created ribbons of vanadium oxide (VO2) thousands of times thinner than a sheet of paper, and combined those with atom-thick ribbons of graphene to form cathodes which were built …

Are Ultracapacitors Ready for Prime Time?

A January 3 article in Automotive Engineering International Online highlights the potential for ultracapacitors to take some of the battery market for vehicle power. The positive side of ultracapacitors would seem to demand their use over that of batteries. They can produce up to 10 times the power of batteries – important in acceleration. They handle temperatures down to -40°C (-40° F), something which drops battery power outputs to near uselessness in many cases. They last forever compared to batteries, can be charged in minutes as opposed to hours, and can even be recycled more fully than batteries – some of whose chemistries are toxic. Prices are dropping quickly. A 3,000-Farad ultracapacitor sold for $5,000 10 years ago. Today, it sells for $50. Battery prices have come down only 30 to 40 percent in the same time. Such a device can store 3,000 Amp-seconds of energy, meaning it could discharge 3,000 Amps at one Volt for one second. More logically, …