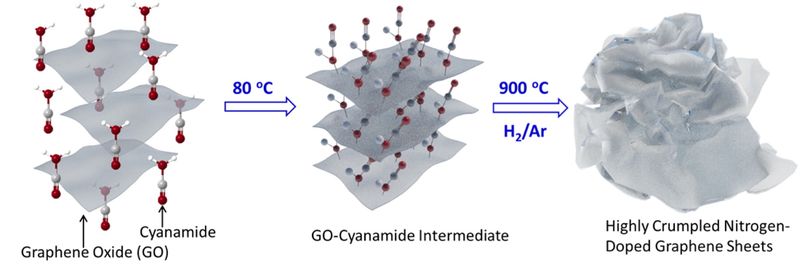

We like to think of things inside batteries as neatly organized, but Pennsylvania State University researchers may have come up with a less tidy way of making cathodes. Researchers synthesized “highly crumpled” nitrogen-doped graphene (NG) sheets with “ultrahigh pore volume” and large surface area (1,158 square meters– 12,465 square feet or about one-third the area of a football field) per gram. This large area and high porosity “enable strong polysulfide adsorption and high sulfur content for use as a cathode material in Li-sulfur batteries.” Interwoven rather than stacked, the wrinkled material provides ample room for “nitrogen-containing active sites.” The batteries, according to the researchers, “achieved” a high capacity of 1,226 milliamp-hours per gram and 75-percent capacity retention after 300 cycles. This demonstrated capacity and longevity is something other experimenters with lithium sulfur batteries have tried unsuccessfully to achieve. Green Car Reports quotes Jiangxuan Song, one of the researchers on the techniques used. “Lithium–sulfur battery cells using these wrinkled graphene sheets …

Tag Archive

Below you'll find a list of all posts that have been tagged as “Jiangxuan Song”