Urs Villiger flew his Traveler TR230 four-seat touring craft about 10 years ago. He started revising the Cessna-like vehicle two years ago, turning it into a more aerodynamic and economical machine. His changes turned the Traveler into a hybrid aircraft and relocated the propeller to the vertical stabilizer.

Reflecting professor Dipl.-Ing. Rudolf Voit-Nitschmann’s configurations he developed for Icare II and e-Genius, the low-drag placement of the drive motor near the top of the vertical fin confines the added drag caused by the propeller’s acceleration of air over the aircraft’s skin to the top-most part of the fin and rudder. Compare the area exposed to propeller blast to that of a conventional nose-mounted engine “tractor” type aircraft.

Icare II (foreground) and e-Genius were both products of Rudolf Voit-Nitschman’s mentoring and students at Stuttgart University. e-Genius was second-place winner in 2011 Green Flight Challenge

On static display at this September’s Smart Flyer Challenge in Grenchen, Switzerland, the newly revised Traveler showed a streamlined nose fairing that holds a gas turbine (reported from a Panavia Tornado fighter’s auxiliary power unit (APU) attached to the UQM motor/generator.

That unit charges the craft’s batteries with up to 100 kilowatts of continuous power output.

Batteries in turn energize the tail-mounted motor that swings a five-blade MT propeller. The motor is being developed to produce 200 kilowatts (268 horsepower) and weigh only 30 kilograms (66 pounds).

Traveler promises to be quiet and efficient with the Mühlbauer five-blade propeller . The concept was first used in the German e-Genius. Photo: Peter Brotschi

All this and more is taking place at Evolaris, a Swiss company that does aircraft structures, batteries, power electronics and batteries and even software – just about everything needed for creating electric airplanes.

Two water-cooled power inverters, housed in carbon fiber and aluminum, control the motor. The redundant units enhance reliability.

Evolaris-devised intelligent software regulates the whole system, communicating between individual components and displaying relevant information for the pilot. In the meantime, Evolaris engineers are making sure everything works a

The drop test proves the limits of Traveler’s landing gear and its ability to withstand a hard landing.

Flap operation is smooth, providing additional wing area for slow landings or enhanced takeoffs.

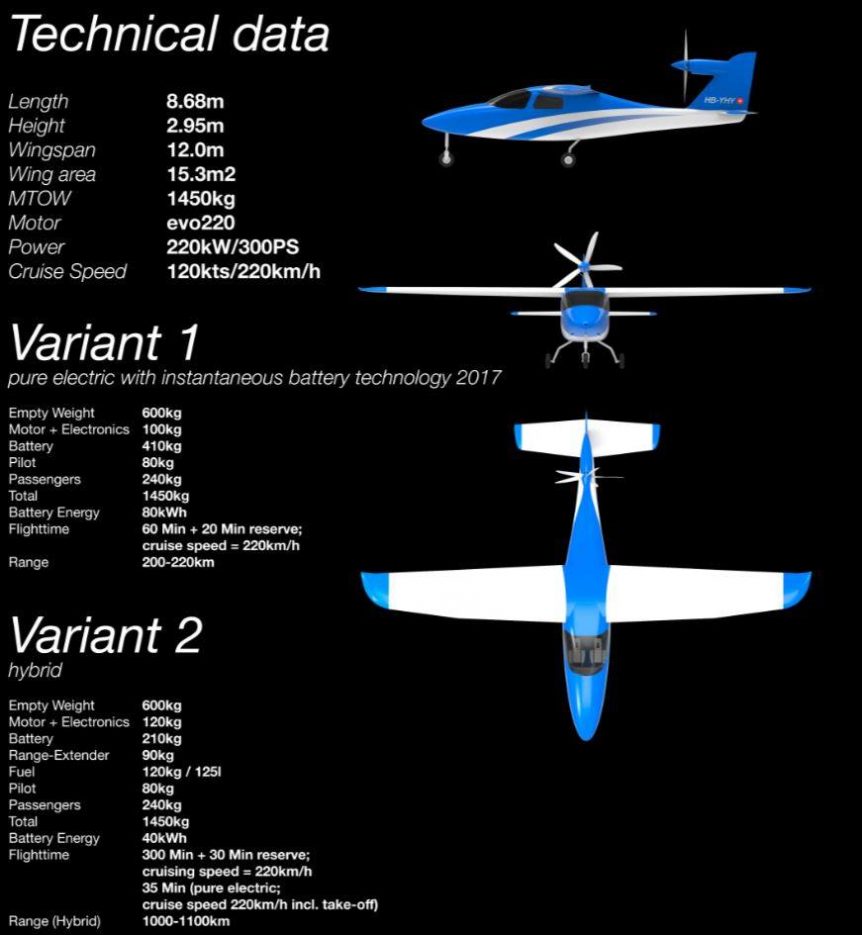

Specifications show the 12 meter wingspan machine will weight 1,450 kilograms (3,190 pounds) fully loaded, including 400 kilograms (880 pounds) of batteries. The motor will produce 160 kilowatts (214 hp.) with a peak output of 220 kW (295 hp.). Traveler will cruise at 220 kilometers per hour (136.4 mph) for up to an hour and 30 minutes.

The latter figure is with batteries only. The range extender should extend that, living up to its name.