Dr. Yeuh-Lin Loo, an Assistant Professor in Chemical Engineering, has led a team of Princeton, University of Texas – Austin, Pennsylvania State University, University of California – Santa Barbara, and Dupont researchers in developing a conductive plastic that takes the place of expensive indium tin oxide (ITO) used in solar cells, flat-screen TVs, and other electronic devices with display screens. ITO, a byproduct of mining, is rare and expensive, but a necessity in today’s electronics. An inexpensive substitute would be desirable in bringing costs down and removing pressure from the growing demand for ITO.

Loo comments on this in the Princeton press release. “The cost of indium tin oxide is skyrocketing. To bring down the costs of plastic solar cells, we need to find a replacement for ITO. Our conducting plastics allow sunlight to pass through them, making them a viable alternative.”

ITO has the characteristic of allowing sunlight to pass through its transparent structure, enabling its collection and conversion into energy in a solar cell. Attempts to create a plastic equivalent were stymied by the fact that molding conductive plastic destroyed at least part of that conductivity.

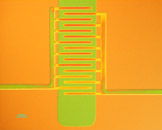

Exploring a new field of engineering called “organic electronics”, Loo and her team found ways to maintain the charge of polymers, while shaping them into useful devices, such as a plastic transistor. According to the press release, “Loo said the technique potentially could be scaled up for mass production presses akin to those used to print newspapers. ‘Being able to essentially paint on electronics is a big deal,’ Loo said. ‘You could distribute the plastics in cartridges the way printer ink is sold, and you wouldn’t need exotic machines to print the patterns.’”

This is similar to the inkjet printer material that Konarka devised two years ago, allowing individuals to print any number of low-efficiency solar panels on plastic film. Nanosolar is also roll printing its solar cells on a metallic foil-based material.

Researchers have hopes for the engineered plastic’s use in low-cost medical devices, which could have far-reaching implications in the third world.

The work of the team, which included a high-school intern (a lucky young lady!), is published online in the Proceedings of the National Academy of Sciences.