With war in Ukraine threatening European and even American oil supplies, many nations are scrambling to develop and deploy cleaner sources of energy. That’s where the U. S. Department of Energy may have a large part in backing big money for battery research. $3.1 billion in funding from the Infrastructure Investment and Jobs Act (IIJA), “will support the creation of new, retrofitted, and expanded commercial facilities as well as manufacturing demonstrations and battery recycling.”

Batteries get Billions, Big Oil Gets Trillions

One sometimes wonders why the governments of the world subsidize Big Oil as much as they do. Big Oil has created the wealthiest corporations since the Roman Empire. First-world nations spend a tremendous amount of their wealth in extracting, refining, shipping and consuming these often dirty fuels. Bill McKibben recently wrote, “…almost half of what we move around the seas is not finished products (cars) nor even the raw materials to make them (steel), but simply the stuff that we burn to power those transformations, and to keep ourselves warmed, cooled, and lit. Which is great news. Because it means that if and when we make the transition to solar power and windpower, we will not just stop pouring carbon into the atmosphere, and not just save money—we will also reduce the number of ships sailing back and forth by almost half. So if you’re worried about almost anything at all that’s going wrong on the high seas—piracy, say, or the hideous sonic effects of all those ships on whales—then you can cut that in half as well.”

Finding energy sources closer to their actual point of use will help reduce the enormous and sometimes hazardous voyages taken to ship oil. A 1989 incident helped start the modern environmental movement, and continues to plague the ecology of the area it despoiled.

The National Oceanic and Atmospheric Administration reports, “On March 24, 1989 the oil tanker Exxon Valdez ran aground in Prince William Sound, Alaska, spilling 11 million gallons of oil. The ecologically sensitive location, season of the year, and large scale of this spill resulted in one of the largest environmental disasters in U.S. history.”

In a side note, Gary Shigenaka, an NOAA Marine Biologist explains, ““I think the big surprise for all of us who have worked on this thing for the last 25 years has been the continued presence of relatively fresh oil.”

The disaster led to a variety of laws and attempts to protect fragile environments, but these seem somewhat futile considering the relentless nature of global warming. Again, developing clean sources of energy with fewer transportation costs and hazards may help.

Building a Better Supply Chain

To that end, the recent announcement by the DOE is a significant increase in funding for batteries and supply chain improvements. The package includes $60 million, “To support second-life applications for batteries once used to power EVs, as well as new processes for recycling materials back into the battery supply chain.”

A team effort, “Battery Materials Processing and Battery Manufacturing” (DE-FOA-0002678) and “Electric Drive Vehicle Battery Recycling and Second Life Applications” (DE-FOA-0002680) are part of the National Blueprint for Lithium Batteries, authored by the Federal Consortium for Advanced Batteries, and led by DOE and the Departments of Defense, Commerce, and State.

DOE lists 12 “areas of interest” for The Battery Materials Processing and Battery Manufacturing:

- Commercial-scale Production Plants for Domestic Separation of Critical Cathode Battery Materials from Domestic Feedstocks

- Commercial-scale Domestic Production of Battery-Grade Graphite from Synthetic and Natural Feedstocks

- Commercial-scale Domestic Separation and Production of Battery-grade Precursor Materials (Open Topic)

- Demonstrations of Domestic Separation and Production of Battery-grade Materials from Unconventional Domestic Sources

- from Unconventional Domestic Sources Demonstrations of Innovative Separation Processing of Battery Materials Open Topic

- Commercial-scale Domestic Battery Cell Manufacturing

- Commercial-scale Domestic Battery Cathode Manufacturing

- Commercial-scale Domestic Battery Separator Manufacturing

- Commercial-scale Domestic Next Generation Silicon Anode Active Materials and Electrodes

- Commercial-scale Domestic Battery Component Manufacturing Open Topic

- Commercial-scale Domestic Battery Recycling and End-of Life Infrastructure

- Domestic Battery Cell and Component Manufacturing Demonstration Topic

More Humane Sourcing

Note the focus on domestic supply chains. Many sources for battery materials, especially lithium, are far away and controlled by regimes not necessarily friendly to U. S. interests. A big part of the bipartisan bill, “Will ensure that the United States can produce batteries, as well as the materials that go into them, to increase economic competitiveness, energy independence, and national security.”

U.S. Secretary of Energy Jennifer M. Granholm explains, “As electric cars and trucks continue to grow in popularity within the United States and around the world, we must seize the chance to make advanced batteries — the heart of this growing industry — right here at home. With funding from Bipartisan Infrastructure Law, we’re making it possible to establish a thriving battery supply chain in the United States.”

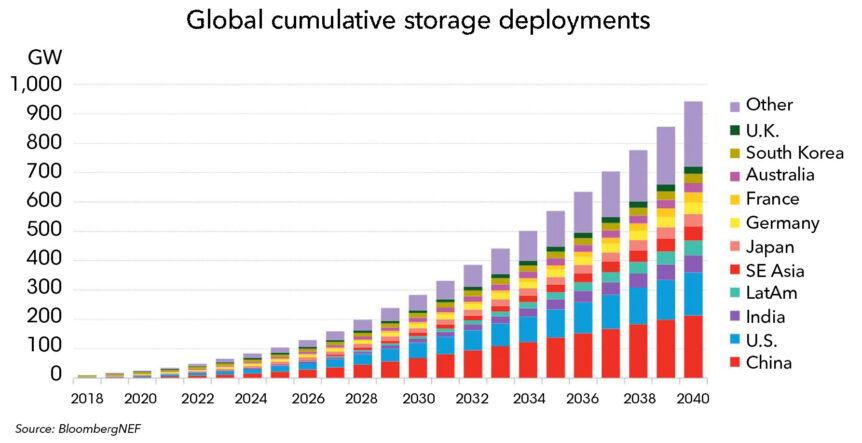

The Verge expands on “the bigger picture.” : President Biden has, “Committed the US, under the Paris climate agreement, to halving its greenhouse gas emissions this decade. To do that, the administration wants to get the power grid to run completely on carbon pollution-free energy by 2035 and make sure that half of all new car sales are electric or hybrid vehicles by the end of the decade.” Such ambitions depend on reliable domestic supplies, a trained work force, and achievable plans for energy storage. Who knew batteries would be this important?

The goals are not without problems which could be debilitating to the cause. DOE’s analysis of U. S. battery production capacity showed the country unable to meet even half of projected demand of lithium-ion batteries for EVs in 2028. The concentration of such resources in unfriendly countries with abominable human rights records leads to, “…Allegations of labor abuses, like a lawsuit against Tesla and other companies for the deaths of child workers,” according to The Verge. They reference a Guardian article.

The Guardian article refers to child deaths in the Democratic Republic of the Congo in extracting cobalt, a vital ingredient in current battery production – one shared by Apple, Dell, Microsoft, and Google. A change in battery chemistry along with a tighter, more domestic supply chain could encompass a more compassionate sourcing program for future energy storage. (Note: although the video below is four years old, conditions are reportedly much the same today.)

The need is not for a child-like desire for a happy solution to our energy problems, but a tough-minded restructuring of our thought processes. We need to take responsibility for how we source energy and energy storage. The administration shows one path toward that goal. Future generations will thank us for our courage or regret our cowardice in where we go from here. It’s up to us.