Suddenly, three battery makers have announced silicon-based 500 kilowatt-hour batteries, a major leap forward for possible use in electric aircraft. The three use varied techniques to achieve this significant energy increase.

Amprius

We covered Amprius’ new battery on March 28, noting its successful record-breaking flights in AALTO’s Zephyr HAPS (High Altitude Pseudo Satellite) aircraft. This frail-looking but obviously over-achieving machine has loitered over the desert of New Mexico and beyond for over 64 days and nights, powered by a combination of sunlight and Amprius batteries.

The batteries in particular just keep getting better. That record was set with the last generation of Amprius cells, but future flights will benefit from the verified performance of their new 500 kilowatts per kilogram batteries. Mobile Power Solutions performed such tests, showing results of >504 Wh/kg and >1321 Wh/l at 25°C.

Pierre-Antoine Aubourg, Chief Technical Officer at AALTO HAPS, looks ahead. “We look forward to taking advantage of Amprius’ 500 Wh/kg cell to further develop Zephyr’s unrivalled stratospheric endurance capabilities. Amprius is a valued current supplier with a great track-record, and we are confident that Amprius’ battery will deliver the capability we need.”

One could think of this as the world’s largest hand-launched model airplane, but that would belie its serious missions. Its ability to hang out in the stratosphere for days at a time, essentially an invisibile observer, has caught the attention of military and civilian customers.

According to AsianAviation,com, “AALTO HAPS has signed a contract to partner in a proof of concept (PoC) demonstration flight of its Zephyr High Altitude Platform Station with Space Compass of Japan, a joint venture between NTT and SKY Perfect JSAT.” In this partnership, Zephyr could, “Deliver year-round 4G/5G low latency mobile connectivity to serve areas previously challenging to cover; network augmentation – to provide overlay or infill coverage to close connectivity white spots, where terrestrial coverage cannot deliver complete or additional capacity; and disaster recovery – the ability to offer connectivity when terrestrial coverage is temporarily cut, and restoring the service becomes a critical life-saving mission.”

The heart of Zephyr’s success is the Amprius cell, and it’s explicated in this video.

CATL

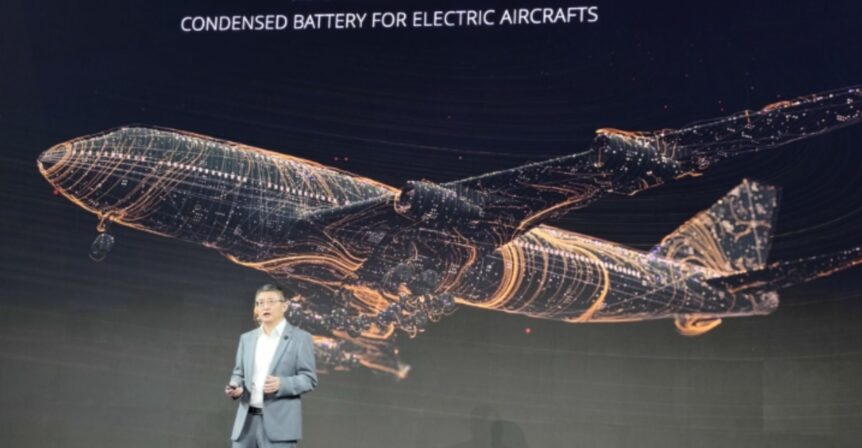

In his address at this year’s Auto Shanghai, CATL’s Chief Scientist Wu Kai unveiled his firm’s highest-output battery. He noted the battery achieves high output and a high level of safety at the same time, often an incompatible pairing. Of even greater interest to readers of this blog, he highlighted CATL’s “electrification scenario” for passenger aircraft.

CATL predicts it can achieve mass production of the “condensed batteries” in a short time. This would open new routes to certification for electric airplanes. Of particular interest are the “micron-level self-adaptive structure[s] that can adjust the interactive forces among the chains, thus improving the conductive performance of the cells and in turn the efficiency of lithium ion transporting while boosting stability of the microstructure.” This would appear to be having one’s cake while consuming hearty quantifies.

CATL claims the condensed battery integrates components such as ultra-high energy density cathode materials, innovative anode materials, separators, and manufacturing processes.

CATL’s Qilin battery started mass production in March, having already been introduced on “high-end” battery electric vehicles in China. CATL hopes to expand terrestrial mobility to air and sea vehicles.

Sila Nanotechnologies, Inc.

California-based Sila Nanotechnologies believes that In the next 5 to 10 years, we will see a $50 per kilowatt-hour (kWh) lithium-ion (Li-ion) battery cell that’s capable of fast charging, 10,000+ cycles, 1 million+ miles, [have] a 30 year calendar life, and produced with abundant raw materials found all around the world and be easily recycled. They spell this out, and more, in a white paper on the future of energy storage.

Sila points out, “Although there are some claims of these attributes now, the challenge is putting it all together in a single cell, without the compromising trade-offs inherent in batteries (for example, a 1 million mile battery is no good if it costs $200/kWh). Achieving the combination will take 5 to 10 years of global innovation.” To that end, Sila is building a plant in Moses Lake, Washington, where Sila’s manufacturing techniques can be refined.

All of these breakthrough batteries promise lower costs per kilowatt-hour, with Sila predicting even $40 per kW-hr. Budgets plus performance will guarantee that more buyers drop by.