Emulating Otto Lilienthal

Vaeridion, a German startup, plans on building a long-winged regional airliner for nine passengers that purportedly transports them on very low levels of energy.

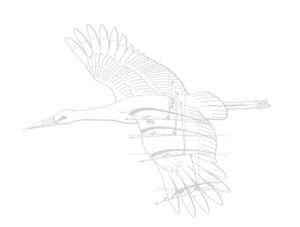

Vaeridion’s wing follows Lilienthal’s basic premise, allows low power and high speeds

Their design philosophy, summed up on the first page of their web site, echoes the idea propounded by Otto Lilienthal, “The key to flying lies in wing design, not in more powerful engines. Vaeridion embraces this ideal in their approach. “As clean energy is scarce and a transition to zero emission mobility is essential, we need a paradigm shift.

Otto Lilienthal’s emphasis on wing design over power has led Vaeridion’s design to high levels of efficiency. Illustration from Lilienthal’s notebook

“Therefore, we have focused on energy-efficient aircraft design that makes a difference. Our electric Microliner can fly with the lowest energy consumption for up to 9 passengers plus crew, for distances up to 500 [kilometers].”

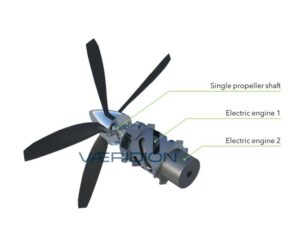

Vaeridion’s Microliner, a slender craft carried on long, high-aspect-ratio wings, will be powered by a remarkable two-motor, single-propeller powerplant.

According to ERA, the European Regional Airline Association, “VÆRIDION is accelerating the green transformation of aviation with a small electric aircraft that will be certified and delivered before 2030. The innovative design of the Microliner is designed for perfect aerodynamics and maximum energy efficiency. This allows high ranges to be achieved with available battery and propulsion technology. Vaeridion’s Microliner enables connections between numerous existing regional airfields.”

Dual-Motor System

As with Vaeridion, Saluqi Motors, Vaeridion’s partner for the Microliner’s electric drive technology, is a relative newcomer, “Founded in 2016 with the aim of developing better, more compact and lighter electric motors and power electronics.”

Dr. Sebastian Seeman, Chief Technical Officer and co-founder of Vaeridion explains, “Our objective is that no single failure of any engine whatsoever will impair continued safe flight and landing. By this novel propulsion approach the Microliner has the potential to feature an even enhanced level of operational safety compared to today’s twin-engine or turbine aircraft, let alone single engine propeller aircraft.”

Saluqi Motors claims, “[Its] parallelization techniques harness the full power for which the components are designed, while increasing rather than decreasing power density, efficiency and reliability. With independent and redundant electric drive systems turning a single propeller, the full system should simplify things like “motor out” failures and ensure continued flight to a safe landing. Similar to the dual-motor Eiger HPD-50D mounted on Calin Gologan’s Elektra Trainer, the Saluqi system is much larger and more powerful to handle the demands of flying nine passengers and crew.

Batteries Redux

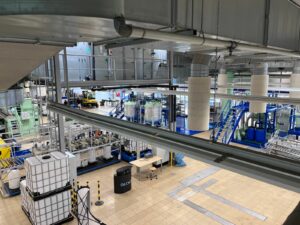

Vaeridion’s partnership with Cylib should ensure a steady supply of batteries for the current and proposed future designs. “The aim is to establish a circular economy for batteries: after about a year of use in aircraft, they are given a second life in stationary battery storage. Once this “second life” is over, Cylib’s recycling technology comes into play. 90 percent of the raw materials should then be recycled.”

Opening of Cylib battery recycling plant will enable reuse of cells, lowering of operational costs

Lilian Schwich, Chief Executive Officer of Cylib promotes this circular economy approach. “Aircraft batteries are an important feedstock for our recycling process. New battery systems are to be tested regarding their recyclability before entering the market. We are looking forward to a close collaboration with VÆRIDION – who have a strong team and a promising technology – to establish a true circular economy across the value chain.“

Ivor van Dartel, Chief Executive Officer for Vaeridion, agrees. “eCTOL Aircraft such as the VÆRIDION Microliner will require a large amount of lithium-ion batteries during its lifetime. As we aim to have a sustainable and circular product strategy from the very beginning, we are excited to cooperate with Cylib – leveraging their insight and leading technology to regain valuable resources – ensuring from the very beginning our battery modules will have circularity designed into them.”

Interior seats nine. Everyone gets a window seat

The foreseeable Market Size for eCTOL (electric Conventional Take Off and Landing) aircraft will range from 5.000 to 10.000 aircraft up to 2040 and would require up to 8 GWh of battery cells yearly for series production and in service replacement. All batteries will have a second life on ground after end of life for aviation is reached. After the second end of life, the modules and battery cells will be recycled to achieve a circular value stream.

The Microliner will one day even offer space for 19 passengers plus crew – from 20 to 30 seats onwards, electromobility will reach the physical limits that are visible today, say researchers. Customcells Manager Dr. Dirk Abendroth emphasizes that today’s batteries with up to 350 watt hours per kilogram can be produced automatically. According to the battery company, this is enough for nine people on board plus luggage and a range of 400 kilometers that can be reached at any time.

In The Not-so-Distant Future

In their presentations at Aero at Friedrichshafen, Dr. Sebastian Seemann and Andreas Löhrke from CustomCells presented the joint vision on battery-electric regional aviation. Their conclusions:

Flying 400km range fully-electric will happen in this decade, and is only possible with the right partners onboard.

OEMs and airports must join forces to ensure the new generation of aircraft is operational before 2030. This came from a panel session with Tine Tomažič (Pipistrel Aircraft), Dominique Decard (Lilium), Phillip Scheffel (APUS Group); moderated by Thomas Mayer .

In the meantime. Vaeridion plans on establishing itself with their nine-passenger initial offering, then expanding to larger craft. Since everyone in Germany lives with 20 kilometers (12.4 miles) of a regional airport, such aircraft could fill a huge need for transport over short distances. We will welcome them here, too.