Seeing the Amprius web site, one would never know that some “dramatic improvements” promised in the terse announcement might mean so much in terms of true breakthroughs.

Neatly centered, Amprius’ total web site is a few lines of discrete text.

Amprius is a leading Lithium-Ion battery developer

Amprius’s silicon technology was originally developed at Stanford University and enables dramatic improvements in the energy density and specific energy of Lithium-Ion batteries.

Amprius is backed by some of the world’s leading investors, including Trident Capital, VantagePoint Venture Partners, IPV Capital, Kleiner Perkins Caufield & Byers, and Dr. Eric Schmidt.

Amprius, Inc., 225 Humboldt Ct. Sunnyvale, CA 94089

But the battery manufacturer has two first-generation product offerings with volumetric energy densities of 580 Watt-hours and 600 Watt-hours per liter. Most lithium batteries fall into a range from 250-500 Wh/l., putting the new cells at the upper limit of such batteries. Both Amprius batteries are now in production and available to original equipment manufacturers, ready for use in smartphones and tablets.

According to Green Car Congress, “The company has also demonstrated greater than 650 and 700 Wh/L batteries with its second-generation and third-generation technology platforms. Amprius plans to begun pilot production of its second-generation batteries later this year.” First-generation batteries are made with silicon anodes: silicon nanowire anodes will appear in the subsequent generations.

Professor Yi Cui helped develop Amprius’ technology at Stanford University and helped found the company. He has spoken at several CAFE Foundation Electric Aircraft Symposia, where he explained the challenges of creating a 10X silicon battery.

In terms of energy density, silicon has more than 10x the theoretical capacity of carbon (4,200 mAh/g compared to 370 mAh/g), charging a lithium silicon cell to expand up to 400 percent, leading to internal fracturing and destroying the battery in a few cycles. Amprius’ answer is to use a new, nanostructured silicon-based anode material to counter such swelling and add to battery life.

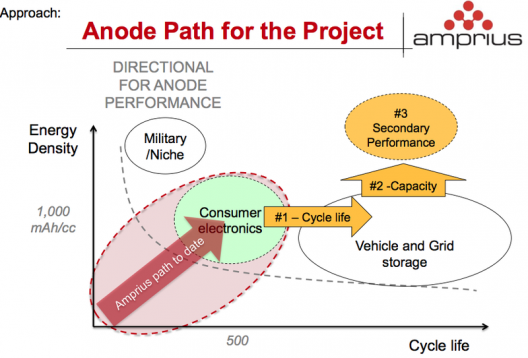

Much of the new technology and the milestones achieved so far is spelled out in a 2012 presentation for the U. S. Department of Energy.

Electronics Weekly reports, “Amprius, the Stanford University spin-out specializing in battery technology, has got its first products out according to the company’s founder, Prof Yi Cui, Associate Professor at Stanford University’s Material Science and Engineering department speaking to the recent Globalpress Summit in Santa Cruz. “The first generation of product is ready right now,” Cui told EW, adding that production was currently “on a small scale.” Cui is applying nanoscale technology to batteries targeting the development of high energy batteries, transparent batteries, printed energy storage devices on paper textile and sponge, transparent conducting electrodes and water nanofilters for killing pathogens. Amprius’ silicon nanowire anodes can, claims the company, improve the energy density of lithium…”

One drawback may be the 500 or so charge/discharge cycles achieved so far. Most lithium cell makers promise 1,000 or more cycles, and some, like Toshiba’s SCIB, can demonstrate over 5,000, although at lower energy densities. This is an ongoing battle in battery development: high power or energy densities equate to shorter cycle life.

The introduction of the second and third-generation Amprius units may see improvements in Wh/g, Wh/l and cycle life, though, a milestone on the road to the 10X battery Dr. Cui has been attempting to craft for the last decade.

Comments 1

Dear Dean,

Have you more information about this:

Intel ISEF 2013 Winners Announced

Eesha Khare,18, of Saratoga, Calif. received the Intel Foundation Young Scientist Award of $50,000.With the rapid adoption of portable electronics, Eesha recognized the crucial need for energy-efficient storage devices. She developed a tiny device that fits inside cellphone batteries, allowing them to fully charge within 20-30 seconds. Eesha’s invention also has potential applications for car batteries.

Regards