Is it possible to combine the best features of batteries and supercapacitors to get both enduring energy storage and bursts of power? Batteries, to varying degrees can store energy and release it over time. Supercapacitors can provide instant, but short-lived power. Even more challenging, can can we form a hybrid structural battery, combining form with function? University of Central Florida researchers think they’ve answered those questions with a battery-supercapacitor hybrid material that could form “power suits” for electric vehicles.

UCF researchers Kowsik Sambath Kumar, Jayan Thomas, and Deepak Pandey with samples of their battery-supercapacitor hybrid material that could form “power suits” for electric vehicles University of Central Florida

Improving on an Earlier Idea

This blog first reported on structural batteries 12 years ago, examining the efforts of Volvo and Dr. Emile Greenhalgh of Imperial College London.

Several approaches have been made to create a structural battery, but the “power suit” combines electrical potency with enough structural strength to resist driving impacts. UCF reports, “This new breakthrough continues this line of thinking, with scientists at University of Central Florida and NASA designing a new material featuring unique properties that allow for not just impressive energy storage potential, but also the strength needed to endure a car crash.”

More recent efforts by Chalmers University in Sweden demonstrated relatively low energy density for the resulting “massless batteries,” but pointed to the weight savings gained by having the structure act as energy storage. At some point, the assumption would be, the weight saved in the structure would cancel the low amount of energy stored, which would be spread over a large part of the structure. The resulting battery would indeed be “massless.”

UCF researchers stacked positively and negatively charged layer of carbon fiber, stacked them in an alternating pattern, and sandwiched graphene between the layers. They attached the stacks, “To electrodes coated with metal oxides increase both the voltage and energy density of the device.”

The team claims the resulting supercapacitor-battery hybrid device, “Is as strong as steel, lighter than aluminum and boasts a bunch of desirable properties for electric vehicles.” Noting that in electric cars, the battery can be 30 to 40 percent of the vehicle’s weight, they claim the structural battery could supplement the usual drive battery to increase range as much as 25 percent. This would mean a that car with conventional battery power able to travel 200 miles (321 kilometers) on a charge could manage 250 mile (402 kilometers).

Because of the supercapacitor part of its makeup, with its quick discharge capabilities, zero-to-60 mph times could be as low at three seconds. Since the materials, “are all non-toxic and non-flammable, important for road safety,” impact damage would be limited to the structure and not to any volatility of its materials. Again, the supercapacitor part could add up to 10 times the charge-discharge cycle life of a conventional EV battery.

Lightweighting and Aerospace

The lightweight nature of the material, according to researcher Thomas, “Is a huge improvement over past approaches that have suffered from issues with toxic material, flammable organic electrolytes, low life cycles or poor performance,”

Luke Roberson, study co-author and a senior principal investigator for research and development at NASA’s Kennedy Space Center, would agree. “This application, as well as many others, could be on the horizon one day as the technology advances in its readiness level,” With potential applications such, “As frames for cube satellites, structures on off-world habitats, or even as part of futuristic eyewear, such as mixed and virtual reality headsets,” self-powered structures could be part of the Internet of Things (IoT).

Consider that thin-film solar cells on the exterior of the sandwich could add to endurance for EVs and even electric aircraft, and the possibilities seem limitless.

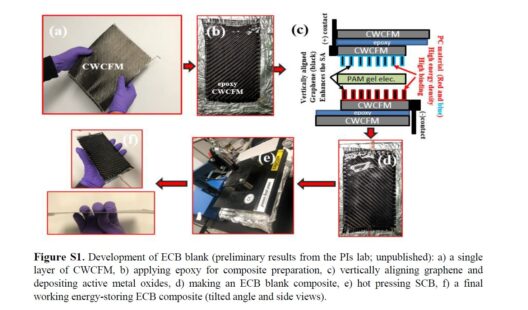

The study’s co-authors, working in Thomas’ lab, devised methods to form, shape, and optimize the composite, as well as developing the method to add metal oxides to the carbon graphene strips. Additionally, they developed a way to vertically align nanoscale graphene on carbon fiber electrodes.

“Energized Composites for Electric Vehicles: A Dual Function Energy-Storing Supercapacitor-Based Carbon Fiber Composite for the Body Panels,” can be found in the January 25, 2022 issue of Small, a peer-reviewed journal. Authors include Deepak Pandey,Kowsik Sambath Kumar,Leaford Nathan Henderson,Gustavo Suarez,Patrick Vega,Hilda Reyes Salvador,Luke Roberson, and Jayan Thomas. The abstract explains their methods, findings and the use of a model car as a demonstration object.

The current electric vehicles (EVs) face many challenges like limited charge capacity, low miles/charge, and long charging times. Herein, these issues are addressed by developing a dual-function supercapacitor-based energy-storing carbon fiber reinforced polymer (e-CFRP) that can store electrical energy and function as the structural component for the EV’s body shell. This is achieved by developing a unique design, vertically aligned graphene sheets attached to carbon fiber electrodes on which different metal oxides are deposited to obtain high-energy density electrodes. A high-strength multilayer e-CFRP assembly is fabricated using an alternate layer patterning configuration of epoxy and polyacrylamide gel electrolyte. The e-CFRP so developed delivers a high areal energy density of 0.31 mWh cm–2 at 0.3 mm thickness and a high tensile strength of 518 MPa (MegaPascals. or 75129.5 pounds per square inch), bending strength of 477 MPa (69,183 psi), and impact strength of 2666 J m–1 (599 pound-force). To show its application in EVs, a toy car’s body panel is fabricated with e-CFRP and the toy car is able to operate using the energy stored in its frame. Moreover, when integrated with a solar cell, this composite powers an Internet of Things device, showing its feasibility in communication satellites.

(Editor’s note: or in electric aircraft.)