Your editor’s first outing at an electric aircraft symposium was in 2009. At that meeting, Dr. Yi Cui, Stanford professor and battery expert, talked about silicon and its energy density being so much greater than that for graphite. He predicted huge advances for battery chemistry – and now he’s delivering. His firm, Amprius, is shipping 450 Watt-hour per kilogram batteries. Unlike many such companies, Amprius is not projecting these numbers several years out, but delivering now.

According to their February 8 press release, Amprius sent its first batch of the energy-dense cells, “…To an industry leader of a new generation of High-Altitude Pseudo Satellites (HAPS).” Your editor guesses that leader is Zephyr, acquired by Airbus and setting endurance records on solar and battery power since its introduction in 2017. One reached 76,100 feet in a 2021 campaign, spending over 36 days (in two flights) at stratospheric heights and equaling the sailplane altitude record set by the Perlan Project in 2018. Both Perlan and Zephyr are Airbus-backed projects.

Amprius’ Technology

Jon Bornstein, COO of Amprius Technologies, announces, “Our proprietary Si-NanowireTM platform and the comprehensive solutions we have developed enable unparalleled performance and continue to sustain our product leadership.”

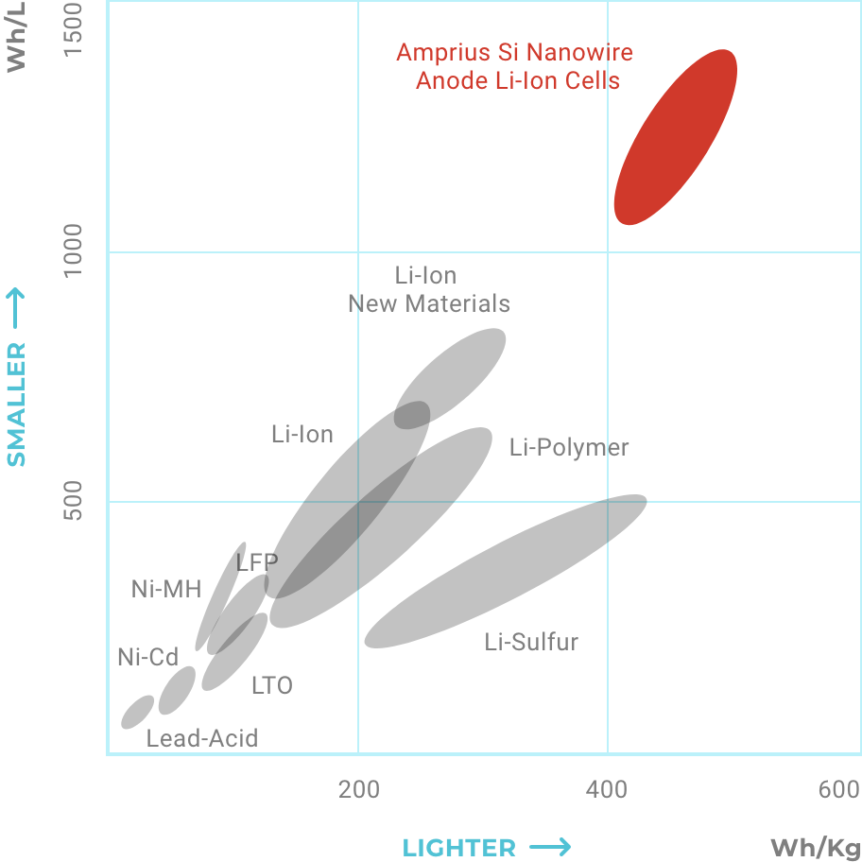

One level of unparalleled performance might be the ability for Amprius cells to charge from 0 to 80 percent in just six minutes. Coupled with 450 Watt-hours per kilogram and 1,100 Watt-hours per liter, the firm would seem to be highly competitive in gravimetric and volumetric energy density.

Part of the secret to its success is Yi Cui’s persistence in pursuing the hope of making silicon work in battery anodes. As he explained 13 years ago, because silicon expands and contracts when charged and discharged in an anode, it tended to crumble and lose its ability to move current at all. Cui worked our many approaches to countering this. His Stanford team managed to create the magic 10X anode six years ago, for instance.

As reported in this blog two years ago, silicon nanowires became the solution that pointed to today’s high energy levels.

Amprius is not yet at the its decade-old goal, but seems to be making progress, noting energy density levels approaching 500 Watt-hours per kilogram – more than double most available lithium batteries. With silicon nanowires at their electrode core, the silicon attempts to swell under charge/discharge cycles, but is constrained by the construction of the wires. This was a problem that kept earlier attempts at silicon batteries from success.

Amprius explains four major factors in the nanowires:

- Nanowires tolerate volume expansion and are rooted to the substrate.

- Nanowires have micro and macro porosity that accommodate swell.

- Nanowires improve Solid-Electrolyte-Interphase and cycle life.

- Anode thickness is reduced to half of a graphite electrode thickness.

Coming Attractions

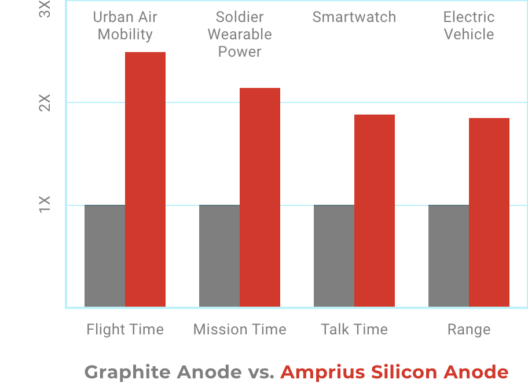

Amprius reportedly, “Has a development contract with an undisclosed leading aerospace group that is working on an all-electric eVTOL air taxi vehicle.” This leads Bornstein to say, “This could be a game-changer for eVTOL aircraft.” He thinks battery-electric propulsion is the most viable solution for urban air mobility craft carrying up to six passengers.

According to Bornstein, Amprius is developing cells for drone delivery applications. Other possible applications for improved batteries could include uncrewed air systems for military operations.

Demonstrated endurance and current availability could make Amprius’ cells the Energizer Bunny of electrically-powered flight.