Fires on or in aircraft are anathema, leaving a pilot and passengers with few options. Even a laptop starting to smoke in the cabin will cause an emergency descent and a diversion to the nearest airport. As designers incorporate larger lithium batteries into new aircraft (and they are essential to motor-driven planes), the need to keep things from self-igniting becomes imperative.

Researchers at Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory, working with funding from the Joint Center for Energy Storage Research (JCESR) discovered, “That adding two chemicals to the electrolyte of a lithium metal battery prevents the formation of dendrites – ‘fingers’ of lithium that pierce the barrier between the battery’s halves, causing it to short out, overheat and sometimes burst into flame.”

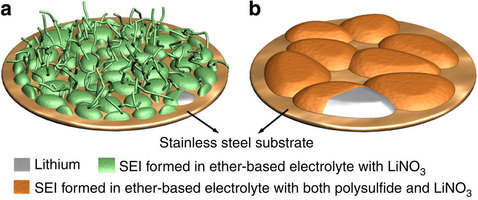

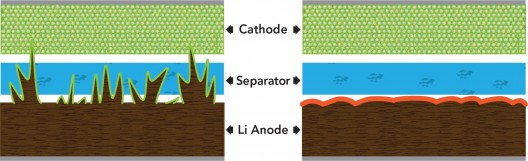

Green fingers of dendrites on untreated electrodes could poke through separator material, cause shorts and fires. Treated electrolyte subdues dendrite fingers

Preventing these shorts will lead to the next-generation batteries being able to take advantage of lithium-sulfur and lithium-air technologies with up to 10 times the energy per weight of batteries now used in electric vehicles.

Yi Cui, who spoke at this year’s Electric Aircraft Symposium, explained the importance of the research. “Because these batteries would be much lighter than today’s rechargeable batteries, they have a lot of potential for extended-range electric vehicles. But one of the things that’s been holding them back is their tendency to form dendrites, which are also the culprit behind overheating and occasional fires in today’s lithium-ion batteries.” Dr. Cui, an associate professor at Stanford University and the Department of Energy’s SLAC National Accelerator Laboratory, worked with colleagues including Fiona (Weiyang) Li, a postdoctoral researcher in Cui’s lab, and Yet-Ming Chiang, a professor at the Massachusetts Institute of Technology.

Dendrite formation occurs when a battery electrode degrades, with metal ions deposited on the electrode surface. As they grow longer, the dendrites pierce the barrier (separator) between battery halves, causing shorts, overheating and fires.

The Stanford news release reports, “In a previous study published last October, Cui and his colleagues reported that they had developed a ‘smart’ lithium-ion battery that senses when dendrites start to puncture the barrier so the battery can be replaced before the situation becomes dangerous. This could offer a solution for millions of batteries now in use in cell phones, laptops and other devices, as well as in electric cars and airplanes.” That development is an early warning system for potential trouble. The newest breakthrough could theoretically make that warning system unnecessary.

Enlarged rendering of dendrites: smoothing by addition of two chemicals to electrolyte promised longer life and more energy from batteries

Cui and company’s latest, different approach adds chemicals to the electrolyte to prevent dendrite formation. Lithium nitrate could also improve battery performance, while lithium polysulfide, formed when a sulfur electrode degrades, “has been considered a nuisance,” traveling to the lithium metal electrode and ruining it.

The team, while brainstorming, realized that the combination of one performance enhancer and one destructive chemical “could potentially react with lithium metal to form a stable, solid interface between the electrode and the electrolyte.”

The team made coin cell batteries like those in calculators and watches, and then added varying concentrations of the two chemicals to an ether-based electrolyte. After running the batteries through charge/discharge cycles, they performed autopsies on the cells, examining the electrodes with an electron microscope and an X-ray technique that reveals their structure, form and chemical makeup.

Adding both chemicals in just the right amounts stopped lithium dendrite formation; harmless pancake-like deposits grew instead. The lithium metal electrode acquired a stable coating that helped protect it from further degradation and actually improved the battery’s performance, with batteries operating at 99-percent efficiency after more than 300 charge/discharge cycles: those treated with only lithium nitrate showed lower efficiency after only 150 cycles.

Fiona (Weiyang) Li, first author of the team’s paper in Nature Communications, said, “This is a really exciting observation. We had been doing experiments all along with these two chemicals in there, but this was the first time we looked at the synergistic effect. This does not completely solve all the problems associated with lithium metal batteries, but it’s an important step.”

Yet-Ming Chiang helped the team interpret their results. He wants to study the next steps, including seeing if this approach will work in larger-scale cells that would be more practical, or with other metals for electrodes, such as magnesium, calcium or aluminum – all of which have the potential of producing even more energy. “Preventing dendrite formation is going to be key to their success,” Chiang said.

The team’s paper, “The Synergetic Effect of Lithium Polysulfide and Lithium Nitrate to Prevent Lithium Dendrite Growth,” was published in the June 17 issue of Nature Communications.