On September 30, the National University of Singapore announced the world’s first energy-storage membrane, with the claim that it “outstrips existing rechargeable batteries and supercapacitors,” and according to Science Daily, “Surpasses existing rechargeable batteries and supercapacitors.”

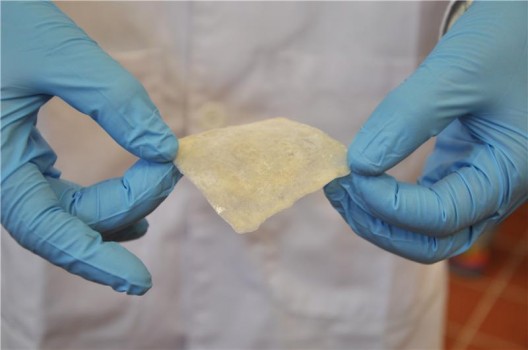

The cheese-cloth appearance looks a bit like a gauze bandage, but when sandwiched between what are alternatively described as two thin metal plates or two graphite plates can hold a significant charge much greater than that of conventional batteries or supercapacitors.

The material, developed by a team from the National University of Singapore’s Nanoscience and Nanotechnology Initiative (NUSNNI), and led by principle investigator Dr Xie Xian Ning, is capable of holding a “charge at 0.2 farads per square centimeter. This is well above the typical upper limit of 1 microfarad per square centimeter for a standard capacitor,” according to the University.

Because energy storage in capacitors is usually measured in farads, How Stuff Works calculates the following to help us understand what that means in more common, AA battery terms.

…A 1-farad capacitor can hold 1 amp-second of electrons at 1 volt.

A 1-farad capacitor would typically be pretty big. It might be as big as a can of tuna or a 1-liter soda bottle, depending on the voltage it can handle. For this reason, capacitors are typically measured in

microfarads (millionths of a farad).

To get some perspective on how big a farad is, think about this:

- A standard alkaline AA battery holds about 2.8 amp-hours.

- That means that an AA battery can produce 2.8 amps for an hour at 1.5 volts (about 4.2 watt-hours — an AA battery can light a 4-watt bulb for a little more than an hour).

- Let’s call it 1 volt to make the math easier. To store one AA battery’s energy in a capacitor, you would need 3,600 * 2.8 = 10,080 farads to hold it, because an amp-hour is 3,600 amp-seconds.

10,800 tuna cans (or one-liter bottles) would take up lots of space – the bottles equivalent to 381.4 cubic feet, the volume of a minivan, and not likely to be used in small airplanes. If all else in that capacitor

could be as capable of storing energy as the University’s new material – a big “if” – that ultracapacitor would be 1/200,000 the size, and theoretically the weight, of a traditional capacitor of the same capacity. This would hold an AA battery’s energy in something little more than a cubic inch in size. Such miniaturization would have a profound effect on electric vehicle development.

Science Daily sees the need for developments such as this in its October 4 story.

“Electrical energy storage and its management are becoming urgent issues due to climate change and energy shortage. Existing technologies such as rechargeable batteries and supercapacitors are based on

complicated configurations including liquid electrolytes, and suffer from difficulties in scaling-up and high fabrication costs. There is also growing public concern and awareness of the impact of traditional energy sources on the environment, spurring a continued search for alternative, green, sustainable energy sources.”

The site notes the new material’s “cost-effectiveness in delivering energy” and its value as “an environmentally-friendly solution.”

It is also considerably less expensive than conventional energy storage devices, which use liquid electrolytes and cost $7 to store each farad. The Singaporean membrane drops the cost to 62 cents

per farad. New Scientist claims, “This translates to an energy cost of 10-20 watt-hour per US dollar for the membrane, as compared to just 2.5 watt-hour per US dollar for lithium ion batteries.”

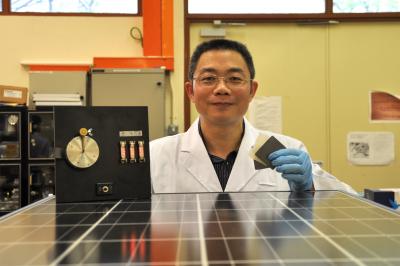

Dr. Xie claims that a simpler configuration than conventional rechargeable batteries and supercapacitors will result in lower fabrication costs. The performance of such devices will also surpass that of existing energy storage devices.

Dr. Xie and the team spent the last 1.5 years reaching their current status, and have successfully filed a U. S. patent for their invention.

The University is taking steps to commercialize the invention, which could be used in hybrid vehicles for instant power storage and delivery, cutting down emissions and extending battery life – although supercapacitors have a practically indefinite life themselves.

Combined with solar panels and wind turbines, the membrane storage devices could provide buffers for periods when the sun was down or dimmed, or when winds were not adequate for existing power needs.

Dr. Xie thinks the affordable and producible nature of this membrane technology will bring about large-scale applications, “and could change the current status of energy technology.”

Dr. Xie’s work can be seen in greater detail in his paper, “Energy technology: Supersizing a supercapacitor” in the journal Nature, or in “Polarizable energy-storage membrane based on ionic condensation and decondensation”, in Energy & Environmental Science.

Comments 9

Energy storage is not measured in farads. Charge on a capacitor is defined by the following equation:

Q = C E

Where Q is the charge in coulombs, C is the capacitance in farads, and E is volts.

So the total charge on a capacitor depends on the voltage as well as the capacitance.

The question that is not addressed here is: What is the voltage rating of this thing?

That will determine whether it is a viable product or not.

This is certainly an exciting development, but I have a lot of unanswered questions…and some issues with your math.

1) the equation for energy stored in a capacitor is E=(CV^2)/2. According to this, one would need about 30,000 farads to store 4.2 watt*hr at 1 volt. This brings up the second issue:

2) Unlike batteries (which maintain a nearly steady voltage until near depletion), the voltage of capacitors drops linearly as the coulombs are drained. This means that we would need some advanced electronics (already available) to convert to steady AC or DC voltage.

3) this means that we could store that AA battery power at 100v or even higher. At this voltage we’d only need 3 farads. At 1000volts we could store 400watt.hrs in those same 3 farads…

Could we replace gasoline tanks in a car? Assuming 2*10^5 farads/liter, one could store the equivalent energy of gasoline (9.7kw.hr) at just under 19volts! Sweet!

Anyway, a very sweet development and if I could I would find several other folks and plunk down a chunk of change right now for a share in the invention: this is going to be big!

(Editor’s Note: My math is always worth checking. I was a liberal arts major, after all.)

Further calculations: since the article states that they expect $.62/farad and $15/watt*hr, they are apparently planning on 17volts.

In my previous post I meant to state that at 19 volts the energy in the capacitor and in gasoline would be equivalent… so at 17 volts this will be 8kw*hr: less than gasoline, but well over the 6.3kw*hr/liter in ethanol. Weight of capacitors will be greater than fuel, but there is far less conversion loss, so it should make a far better replacement for gasoline than our current battery technology.

*embarrassed*. 10 to 20 watt*hr/$, not $10 to $20 per watt*hr. This changes everything:

The cost for a 24kw*hr capacitor would be $1,200 to $2,400 (I believe this is what the Leaf contains).

The Leaf runs for about 3 miles per kw*hr, so one could obtain a range of about 300 miles with a 100kw*hr power pack. This would cost $5k to $10k…and should last for a very long time before needing replacement.

If the stuff costs $.62/farad and will store 10 to 20 watt*hr/$, then we are looking at 6.2watt*hr/farad to 12.4watt*hr/farad.

Voltage: 200V to 300V

Since a typical 1 farad electrolytic capacitor is about a liter, this new one should be about 200,000 farads per liter. This equals 1200 to 2400 kw*hr/liter vs gasoline’s 10kw*hr/liter.

Hmmm….somehow I can’t imagine that being correct. Let’s try another way:

Capacitance is about 2×10^5 as much as standard electrolytic capacitors and one of those can store 1.5 joule/gram, so I expect these new ones would hold 80kw.hr/kg (3×10^8J/kg)….far better than even gasoline at 4.5×10^4J/kg.

*sigh*. I worry that any storage medium that claims to store so much more than gasoline is probably an error. Or perhaps I made the error….someone check my numbers..

hydrophillia,

You are vindicated.

One of the figures in the original article has to be wrong.

The new material cannot be both 62 US$ cents per farad …and….10 to 20 watt hours per US$.

15 watt hours is (by my reading of it) 54,000 farads, which would make it .002 cents per farad cost. So I am going to assume that the real figure was .006 cents per farad and calculate for a 40 kwhr battery which is around 144 million farads.

So while registering Bert Bigelow’s comment above, and blithely ignoring it for the moment, this would put the cost of a 40 kwhr capenergy cell at US$8,928. Sounds bloody good to me. When can we have them.

Note. I have no real knowledge in this field and am going on the figures as presented while rearranging them with the truly incredible…RealCalc…ap on my android phone.

Other problem,

If the storage capacity of the material is .2 farads per square centimetre then that would be 2000 farads per square metre. If the storage film was .5 mm thick, remembering that it requires sandwiching between 2 metal films for charging and discharging, then that would be 4 million farads per cubic metre. Or 4 million divided by 3600 for watt hours (1 farad being approximately equal to 1 watt second) to give a storage capacity of 1.1 kilowatt hours per cubic metre. That is a great result for a capacitor, but not so great for a flying storage device.

Maybe the storage film is thinner, of the capacity is greater than .2 per sq cm, or there is more to it than can be deduced from the basic information in the article.

(Editor’s Note: This was added 10/19/2011 by Hydrophilia. Your editor decided to add it to the considerations already expressed, rather than expunging the previous thoughts. This gives more depth to the overall “debate.”)

So what does this mean?

The new capacitor is supposed to hold 200,000x as many farads as standard electrolytic capacitors per cm^2, cost $0.62/farad and $0.05 to $0.10/watt*hr.

Gasoline holds about 10kw*hr/liter.

Common 1 farad capacitors run at about 17volts.

The energy in a capacitor is (CV^2)/2 where C is farads and V is voltage.

From this we can derive

1) watt*hrs per farad: ($0.62/farad)/($0.10(or $0.05)/wh)=6.2 to 12.4 watt*hr/farad (=22kJ to 44kJ/farad)

2) The planned operating voltage: joules=(CV^2)/2, so V=sqrt(2*J/C)=sqrt(2*22,000/1)= 200V to 300V

3) assuming that the plate spacing will be similar for similar operating voltages, we can estimate that the new capacitor density is 200,000 farads per liter if operating at 17 volts. (I do not know how plate spacing varies with voltage or I could estimate power density at full operating conditions.)

4) This would allow an energy density of 30*10^6 joules/liter or 8kw*hr/liter, midway between gasoline and ethanol. Assuming a greater mass density than gasoline, but more efficiency in storage-to-wheel transfer, we are probably looking at a roughly similar storage mass to mile ratio as conventional fuels.

This storage is better than gasoline because it allows 2-directional charging between grid and car for load levelling (important for standard generating sources, but even more important for alternative sporadic sources). It also allows us to easily charge at night when generators are giving away power (well, on the wholesale market). It also allows us to use our cars as a backup power source for our homes and will cost very little per mile for the electricity and for wear and tear on our power storage.

It is better than batteries because it will allow a lot more charge-discharge cycles before wearing out, thus making electric cars and load levelling more cost effective. It is also supposed to be cheaper than the cheapest batteries per watt, but will certainly have a faster charge-discharge rate than even the best batteries.

The disadvantages are that it will require some fancy electrical conversion technology to deal with the linear relationship of voltage and charge. It will also cost a bit up front: to get a 300 mile range with the Nissan Leaf (24kw*hr=100 mile range) would cost

$3,600 to $7,200, not including electronics.

Bill,

How do you get a farad equals about a watt*second? Using Joules=CV^2/2 and watt*hr=joule/(3600), I figure 1 farad at 200volts will hold 45kJ or 6watt*hr, roughly 20,000 times as much as you found.

other thoughts:

Some important factors here are energy capacity per $, per liter, and per kg. If the numbers quoted in the article are correct, then the capacitors will hold operate at 200V to 300V and store power for five to ten cents per watt*hr. Until we know construction details, we won’t know the capacity per liter or kg. I assume the price quoted per watt*hr is for a capacitor, not just the membrane.

Another important factor is leakage current: batteries typically don’t lose more than a percent per day, but a capacitor might lose that in a minute, making it unsuitable for anything other than load leveling (regenerative braking, acceleration, etc). I have no information on leakage for this technology, but guess it will not work as a replacement for batteries. *sigh*

We are still quite a ways off with this, but…

Modern super/ultra-capacitors have very minimal leakage I would expect the same here.

Normalization of voltage to handle a linear loss is pretty standard and pretty basic circuit.

Super/ultra-capacitors over 1 farad typically have a range of 2.5-2.7 volts,so your calculations should be a LITTLE closer to what is described in the article.

The usual life expectancy of a properly treated capacity is said to be about 100k cycles, though in all honesty a properly treated capacitor would have no reason to fail ever.

It appears that this is simply (or not so simply) an alternative to the electrolyte used in current tech. If you were to marry this with graphene in place of the “metal plates”, this could definitely be of some serious interest.

(Follow on to previous comment)

With more research I found http://www.rexresearch.com/ning/ning.htm which includes an example of what I was saying about use of graphene. When sandwiched between two layers of hydrated graphene (graphene must be kept hydrated so as to prevent the sheets from forming to simple carbon black) they were able to produce a capacitor that had a 1.86-2.02v threshold with an energy density of 3.6Wh/kg.

Unfortunately, though this is something to write home about, it is not a viable alternative to batteries (which are currently between 100 and 350 Wh/kg).