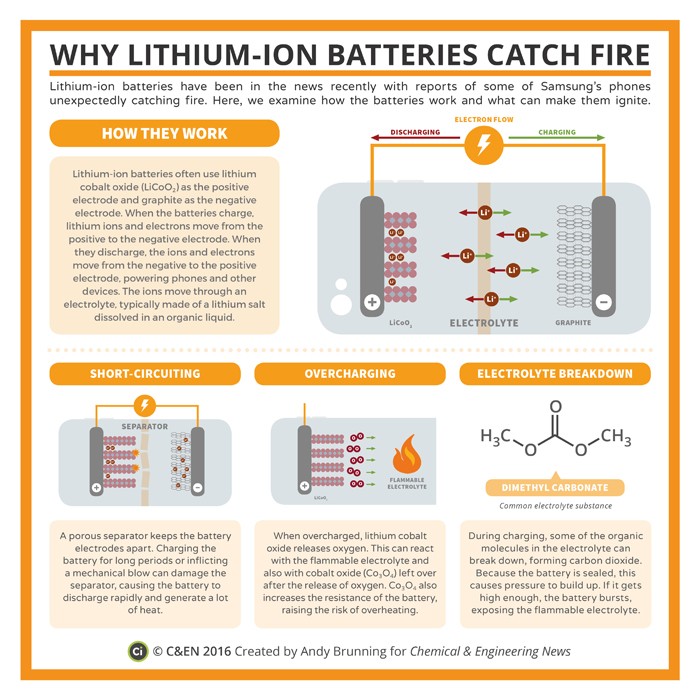

Hyundai, the Korean carmaker turning increasingly to electric vehicles, has teamed with Ionic Materials, a Massachusetts-based battery developer to work on an innovative solid-state battery. Ionic’s solid polymer electrolyte technology promised to improve battery safety and performance. Liquid electrolytes are often blamed for disastrous battery fires, so the search for a solid-state alternative is one way to counter the problem.

Hyundai’s CRADLE (Center for Robotic-Augmented Design in Living Experiences), “corporate venturing and open innovation business,” is investing in Ionic to gain access to the company’s technology, which also supports lithium-ion cells with no cobalt in their cathodes. Reducing or eliminating cobalt in their batteries may be a major incentive for Hyundai. Forbes reports, “Carmakers, such as Germany’s BMW, and electronic gadget makers, such as Apple, are scouring the world for supplies of cobalt, a rare metal that has tripled in price over the past year to $80,000 a ton, with 60% of global supply coming from the bloody Democratic Republic of Congo.”

Environmental “points” for making clean-energy automobiles may be overshadowed by bad publicity related to “blood minerals,” much like the negative appearance in wearing “blood diamonds” or other conflict gems.

Expected Benefits of Solid-State Batteries

Ionic Materials cites the following as advantages of their solid-state battery technology:

- Inherent Safety: Eliminates safety issues with liquid electrolytes.

- Higher Performance: Enables higher energy anodes and cathodes.

- Lower Cost: Reduces battery cost through less expensive chemistries and manufacturing (including the elimination of cobalt).

“’Ionic Materials’ breakthrough technology could significantly improve battery technology today,’ said John Suh, vice president of Hyundai CRADLE. ‘We are always looking for ways to ensure our cars provide the highest level of clean and efficient solutions. Our investment in Ionic Materials will keep us at the forefront of battery development, allowing us to build better eco-friendly vehicles.’”

A Wired magazine article titled, “Batteries Still Suck, But Researchers Are Working on It,” quoted Ionic Materials CEO Mike Zimmerman explaining, “’People are working on variations of anodes and cathodes, but the real block [to battery advancement] is the electrolyte, which is what we’re trying to improve upon.’ He noted that ceramic and glass can be brittle, and can give off gases when exposed to moisture, so he believes those solids are less-than-ideal solutions for solid-state batteries.” His polymer-based electrolyte avoids some of these problems while offering other benefits.

According to Ionic Materials, “Key properties of ionic materials’ polymer include:

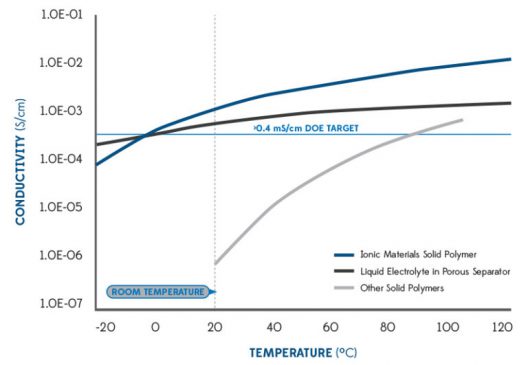

Ionic Materials’ solid-state electrolyte exceeds Department of Energy’s expectations for conductivity, and performance of other solid-state materials and liquid electrolytes

- Up to 1.3 mS/cm at room temperature (a measure of electrical conductivity. This number is competitive with figures for liquid electrolytes)

- Lithium transference number of 0.7

- High voltage capability (5 volts)

- Can accommodate high loadings in the cathode

- High elastic modulus

- Low cost precursors

- Stable against Lithium

- Conducts multiple ions”

Zimmerman concludes, “The investment by Hyundai represents another key company milestone and demonstrates our rapid momentum as we develop polymer-based materials for solid-state batteries. With the ongoing help of our investment partners, we have expanded our facilities and are adding to our team to meet the ever-growing demand for this technology.”

Further advancements made possible by Ionic Materials’ polymer will support additional high-energy and eco-friendly battery chemistries, including lithium metal, lithium sulfur and inexpensive and low-cost rechargeable alkaline batteries.