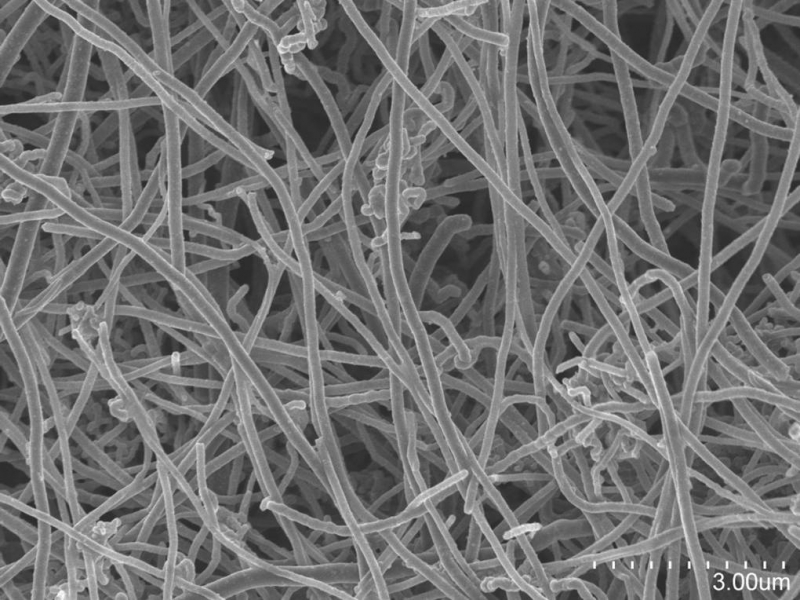

Dr. James Tour of Rice University makes news regularly with different ways of making better batteries. His latest, a thin-film coating of carbon nanotubes, will enable lithium metal batteries to potentially achieve their full potential. According to the Tour Laboratory, that potential is worth considering. “Lithium metal charges much faster and holds about 10 times more energy by volume than the lithium-ion electrodes found in just about every electronic device, including cellphones and electric cars.” This promise is offset by problems with dendrite growth, the intrusion of tooth-like projections from the surface of the anode metal. If these growths expand far enough, they poke through the battery’s electrolyte and severely limit battery life. Worst of all, if the dendrites reach the cathode, they short out the battery, and possibly cause thermal runaway and fires. Tour and his student researchers have found that coating the lithium metal electrodes with a thin layer of carbon nanotubes keeps dendrites under control, and allows …

Capturing Carbon and Making Airplanes from It

Climate scientists have tracked the growing percentage of carbon dioxide (CO2) in the air, and noted a correlation between that rise and global warming. Scientists from Michael Mann to Benjamin Santer have measured the changes in CO2 levels against climate change, with 97 out of 100 climate scientists accepting that human activities and rises in CO2 (and other greenhouse gases such as methane) are affecting our overall climate. Not to start an argument about this matter, this entry looks at a novel method of removing CO2 from the atmosphere and using it to make possible carbon materials that would be used in aerospace and other components. The question of carbon removal usually includes some method of storing it. Futurism.com has a great overview (too large to display here) that shows those methods. One enterprising group of scientists avoids the costly and difficult means of carbon storage and instead focuses on retrieving carbon and turning it into carbon wool, a usable …

Corncobs as a Source of Supercapacitors?

Researchers at the Illinois Sustainable Technology Center at the University of Illinois report, “that wood-biochar supercapacitors can produce as much power as today’s activated-carbon supercapacitors at a fraction of the cost – and with environmentally friendly byproducts.” Junhua Jiang, senior research engineer at the Center, has been reducing wood and cellulose products such as corncobs to biochar by heating the fibers in a reduced oxygen environment. This pyrolysis process creates a porous, black substance that can be used as electrodes in supercapacitors. While other researchers use carbon black or more advanced forms of carbon such as nanotubes, this more humble approach yields equal or better performance at a fraction of the cost of the more labor-intensive methods. Many of the alternatives obtain their carbon from fossil-fuels, making biochar the environmental option. Jiang notes, “Supercapacitors are ideal for applications needing instant power and can even provide constant power – like batteries, but at lower cost,” adding that they are useful in transportation, electronics …

Taking Paper Batteries to the Next Level – Origami

Almost four years ago, this blog reported on Dr. Yi Cui’s “painted battery,” a method of coating even paper with carbon nanotubes and silver nanowires, with the coated paper being able to store energy. Adding origami to the concept, Arizona State University researchers have folded a paper-based lithium-ion battery and managed to demonstrate a 14-fold increase in areal energy, or energy density per unit of area. This has serious implications for batteries that can be printed on roll paper and which have the requisite flexibility. More rigid batteries might crack under the strain, for instance, and achieve negative results from being folded. “’Foldable batteries may be useful for powering devices that have limited space on board,’ coauthor Candace Chan, Assistant Professor of Materials Science and Engineering at Arizona State University told Phys.org. “’Furthermore, with the development of foldable paper-based electronics demonstrated by other research groups recently, a battery that also can be folded may become important for integration of the …

Getting Batteries in Line

In another bid to create the much-hoped-for 10X batteries, researchers at North Carolina State University are rolling their own. As noted in many articles, lithium batteries infused with silicon have a bad habit of swelling and contracting as they charge and discharge, pulverizing the silicon eventually. Depending on the surrounding materials, the destruction can take place fairly quickly, leading to reduced cycle life for the battery. North Carolina scientists are fighting to extend battery life, though, with what they call “A Novel Nano-architecture for Flexible Lithium Ion Battery Electrodes,” part of the title of their paper in the journal Advanced Materials. Many battery electrodes are some form of graphite composite, and the impetus to wrap these anodes or cathodes in silicon has strong motivation. “Putting silicon into batteries can produce a huge increase in capacity—10 times greater,” Dr. Philip Bradford, assistant professor of textile engineering, chemistry and science at NC State says. “But adding silicon can also create 10 times …

Making Graphene and Carbon Fibers Even Lighter and Stronger

While scientists at Columbia University have used chemical vapor deposition (CVD) to create large sheets of stronger-than-average graphene, a research team at Massachusetts Institute of Technology (MIT) has found ways to weave stronger carbon nanotubes. James Hone and Jeffrey Kysar, professors of mechanical engineering at Columbia University, learned that the enormous strength of graphene is usually achieved in only small patches. The “grain boundaries” for larger sheets were often far weaker than the theoretical strengths of which the material is capable. That strength is phenomenal. Hone explains, “It would take an elephant, balanced on a pencil, to break through a sheet of graphene the thickness of Saran Wrap.” Results of their study were published in the journal Science. The paper’s lead author, Gwan-Hyoung Lee, a postdoctoral fellow in the Hone lab, says, “Our findings clearly correct the mistaken consensus that grain boundaries of graphene are weak. This is great news because graphene offers such a plethora of opportunities both for …

Imperfect Carbon as Good as Pricy Platinum

The expense of platinum catalysts has been an impediment to the development of fuel cells and metal-air batteries. Scientists at Stanford University may have found an inexpensive, higher-performance alternative in “unzipped” carbon nanotubes that show an imperfect face to the world. Findings published in the May 27 online version of the journal Nature Nanotechnology quote chemistry professor Hongjie Dai, co-author of the paper. “Platinum is very expensive and thus impractical for large-scale commercialization. Developing a low-cost alternative has been a major research goal for several decades.” With platinum ranging from almost $800 to over $2,200 an ounce, carbon nanotubes, with their conductivity and inexpensive production costs provide a desirable combination of performance and price. Nanotubes are rolled-up sheets of graphene, a one-atom thick layer of pure carbon – 10,000 times narrower than a human hair. Dai’s team nested two or three nanotubes, each smaller than the next layer outward, an amazing feat considering the submicroscopic size of the tubes. To …

Dipping and Coating for Better Batteries

Could dipping electrodes in a secret sauce improve supercapacitor and battery endurance and power? Could coating cell internals be the flavor of the month? These recipes for better batteries may improve things at a better than normal rate, if California researchers have anything to say about it. Working with his compatriot Dr. Jaephil Cho in South Korean, Dr. Cui of Stanford University has been a leader in developing improved battery technology, even developing a painted paper battery. In an appearance at the 2009 Electric Aircraft Symposium, Cui explained a basic truth of battery development – that improvements generally created about eight percent greater power or endurance in cells every year, leading to a doubling of battery capabilities every seven and one-half years. He aims to improve that rate of change in batteries and ultracapacitors. Although ultracapacitors are able to charge and discharge rapidly, they are only about one-tenth as energy dense as batteries of equivalent mass. Cui and colleague Zhenan Bao …

Taking it to eXtremes

“If I were to make a prediction, I’d think there’s a good chance that it is not batteries. But capacitors.” Karl Young, CEO of eXtreme Capacitor, Inc. started his presentation at the fifth annual Electric Aircraft Symposium with these words from Tesla Motor’s Elon Musk. The reference to capacitors superseding batteries as an energy source for electric cars came from Musk’s address at the Cleantech Forum in San Francisco on 16 March 2011. Young’s talk before the April 29 gathering in Santa Rosa, California detailed the double-layer supercapacitors his company produces, and what Young feels are the advantages these have over “traditional” lithium and other batteries. He is “trying to overcome the issues of batteries,” including, according to Young, their weight, slow charge and discharge times, their short operational lifetimes (typically 500 to 3,000 cycles), and their toxicity and flammability. Young contrasted that with the specifications for his eXtreme X-Cap™ “double-layer capacitor-based energy storage technology,” which can last through over …

The Happiest Materials Scientist

According to his NASA biography, “Dr. Ajay Misra, a member of the Senior Executive Service, is Chief of the Structures and Materials Division in the Research & Technology Directorate at the NASA Glenn Research Center in Cleveland, Ohio. In this position, Dr. Misra has the responsibility for planning, advocating, coordinating, organizing, directing and supervising all phases of Division research and business activities.” At the fourth annual Electric Aircraft Symposium in Rohnert Park, California in April 2010, Dr. Misra was among the most charming and happiest of presenters – probably because he had so many happy things to talk about. Much of the joy comes from the continuing revelations about the characteristics of carbon and boron nanotubes. They turn out to be absolutely wonderful for thermal, structural, battery, capacitor and motor applications. Dr. Misra’s talk sounded at times like a pitch for a wonder cure-all, but one backed with solid scientific precepts. Boron nitrate nanotubes have better high-temperature characteristics than carbon …

- Page 1 of 2

- 1

- 2