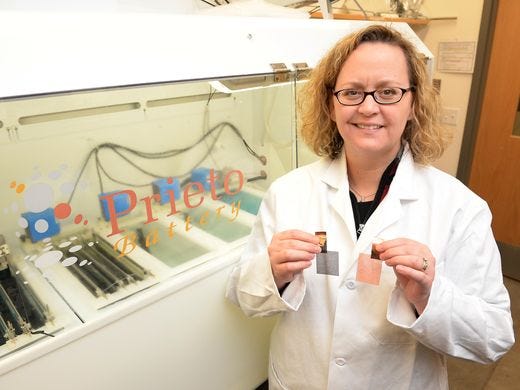

Dr. Amy Prieto created her namesake battery a decade ago, and has been seeking funding and other support for its development ever since. It gained such funding from Stanley Ventures in 2016. Prieto Battery, as reported by GreenCarCongress.com then, is, “A company commercializing a 3D Lithium-ion battery technology (earlier post), announced a strategic investment from Stanley Ventures, the venture arm of Stanley Black & Decker, a world-leading provider of tools and storage, commercial electronic security and engineered fastening systems.” Possibly more important that money, Dr. Prieto’s battery recently received third-party validation of its claimed safety and performance attributes from Energy Assurance, LLC. GreenCarCongress reports, “Specifically, Prieto had a group of fully assembled batteries containing their proprietary 3D anode tested against an array of UL (Underwriters Laboratories) and IEC (International Electrotechnical Commission) standards for Li-ion chemistry. All of Prieto’s batteries had 100% success rate with zero failures.” Dr. Prieto seems happy with these results, stating, “These results validate the science and manufacturing …

Recycling and Reusing Carbon in Jet Fuel

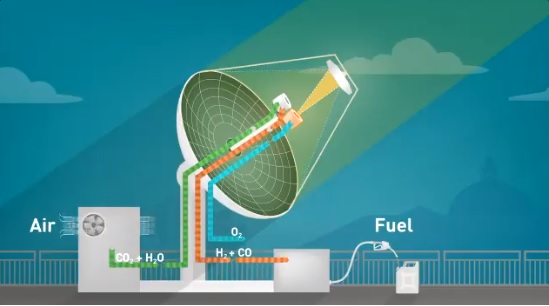

ETH Zurich (the Swiss Federal Institute of Technology), is recycling and reusing CO2 to make jet fuel as part of a carbon-neutral process. This is not a new idea, with others’ approaches to this detailed in earlier blog entries here, here, and here. Centered on a solar collector/reactor on the roof of ETH’s Machine Laboratory building in Zurich, researchers have “developed a novel technology that produces liquid hydrocarbon fuels exclusively from sunlight and air and have demonstrated the entire thermochemical process chain under real field conditions.” Extracting CO2 and water directly from ambient air through an adsorption/desorpton process, the system feeds these free materials into a solar reactor that is at the focus of the parabolic reflector that heats them to 1,500° Celsius. A cerium oxide structure in the reactor enables a redox (oxidation-reduction reaction)* cycle, with syngas an end product. This gas can be processed into a commercially-viable hydrocarbon fuel through conventional methanol or Fischer-Tropsch synthesis, according to GreenCarCongress. …

Kreisel Brothers – Austrian Entrepreneurs

We keep hoping for the long-awaited 10X, or even 5X battery that would make electric aviation “pop” in a significant way. The Kreisel brothers in Austria are not developing new batteries or chemistries, but through careful design and manufacturing techniques, manage to reduce weight in their battery packages – one example being the two “ultra-lightweight battery units” they supply for PC-Aero’s Elektra One. With a total weight of “just 64 kilograms,” (140.8 pounds), the packs “provide [an] efficient and reliable energy supply for a range of 400 kilometers (248 miles)… a flight duration of three hours [and a] speed of 160 kilometers per hour (99.2 mph).” Each pack stores 5.8 kilowatt-hours of electrical energy, or 5.52 kw-hr./kg. That’s roughly an eight-percent savings over the Teslas’s battery, if all else is equal. It might be a harder number to achieve in a small package, there probably being a certain irreducible minimum of things that weigh down the small package disproportionately more …

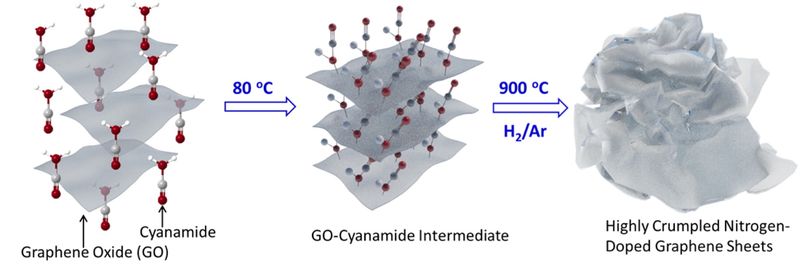

Rumpled Cathodes Benefit Lithium Sulfur Batteries

We like to think of things inside batteries as neatly organized, but Pennsylvania State University researchers may have come up with a less tidy way of making cathodes. Researchers synthesized “highly crumpled” nitrogen-doped graphene (NG) sheets with “ultrahigh pore volume” and large surface area (1,158 square meters– 12,465 square feet or about one-third the area of a football field) per gram. This large area and high porosity “enable strong polysulfide adsorption and high sulfur content for use as a cathode material in Li-sulfur batteries.” Interwoven rather than stacked, the wrinkled material provides ample room for “nitrogen-containing active sites.” The batteries, according to the researchers, “achieved” a high capacity of 1,226 milliamp-hours per gram and 75-percent capacity retention after 300 cycles. This demonstrated capacity and longevity is something other experimenters with lithium sulfur batteries have tried unsuccessfully to achieve. Green Car Reports quotes Jiangxuan Song, one of the researchers on the techniques used. “Lithium–sulfur battery cells using these wrinkled graphene sheets …

- Page 2 of 2

- 1

- 2