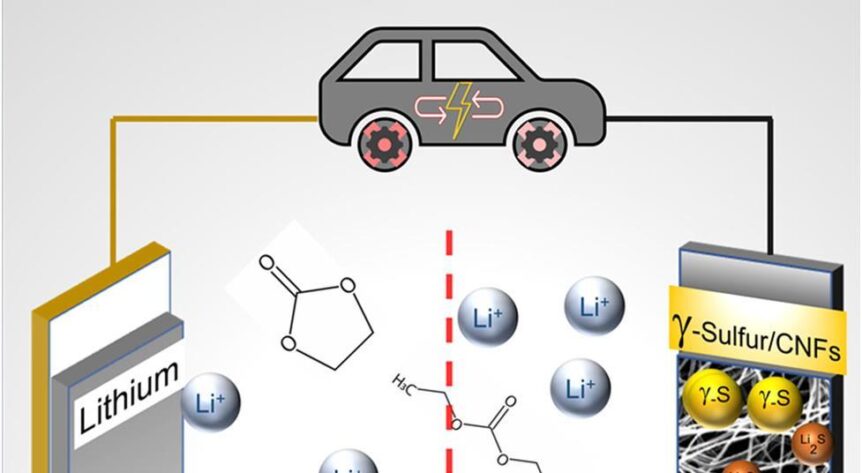

Chained to Supplies? A sulfur battery uses an abundant, energy-dense material not subject to the limitations of many supply chains like those for lithium, cobalt, and nickel – all necessary for batteries as they are now constructed. William Lockett, writing for freethink.com, highlights the potential magnitude of a discovery by Drexel University researchers. “Every now and then, revolutionary technology seems to spontaneously appear out of thin air and change our world. Dynamite, penicillin, X-ray machines, and even microwaves are all examples of such revolutionary accidental discoveries. “Well, this year we may have had yet another. However, this time it is set not only to revolutionize the way we live, but potentially save our planet from looming climate change by unlocking an elusive technology: lithium-sulfur batteries.” Drexel’s Accidental Discovery Drexel University may have come up an answer to that need, even big enough to justify Lockett’s enthusiasm. Vibha Kalra, PhD. leads the school’s Department of Chemical and Biological Engineering, and reports …

Sion Power’s EV Battery

Sion Power’s EV Battery 400 Watt-hours per kilogram is a long-awaited minimum expectation for what it will take to get electric aviation off the ground. Sion Power® of Tucson, Arizona will introduce its Licerion® 17 Amp-hour pouch cells at the Battery Show North America in September – claiming to fulfill that expectation. The large-format pouch cells come in a compact 810 Watt-hours per liter size, last over 800 cycles and can be charged to 80-percent of their rated capacity in 15 minutes, according to Sion. Sion Power is shifting from its lithium-sulfur chemistry to lithium-metal technology. Their Li-S cells powered Airbus’ Zephyr® 7 HAPS (High Altitude Pseudo Satellite) to a record for continuous flight. According to Tucson Tech, “In 2014, lithium-sulfur batteries custom-made by Sion helped power Airbus’ Zephyr 7 solar-electric unmanned plane to fly for 11 days on sun power during the day and battery power at night.” From Lithium-Sulfur to Licerion® In a paper on the subject, Sion …

Oxis Batteries to Fly in Two Airplanes

While we wait yet another five years for commercial development of each newly announced but promising battery chemistry, one company has its cells ready to fly in Bye Aerospace’s eFlyer 2 and in Texas Aircraft’s Colt S-LSA. Oxis Energy has managed to leapfrog lithium-ion makers with its lithium-sulfur battery packs packing 400 Watt-hours per kilogram. Considering the best announced pack-level li-ion performance has been 260 W-hr/kg, the leap is significant. Batteries, for now, are at the heart of electric aircraft. Until Doc Brown’s Flux Capacitor or a hydrogen fuel cell with Dollar Tree refills comes along, batteries are battling it out for our airborne dollars. Lithium-ion remains in the forefront, with Tesla staging its shareholders’ meeting and its long-anticipated “Battery Day” on September 22. Elon Musk has been dangling the promise of a million-mile battery for the last year, which may tie in with Chinese manufacturer Contemporary Amperex Technology (CATL). According to Bloomberg, CATL’s, “Chairman and founder Zeng Yuqun said …

Airbus, Williams Team to Expand Zephyr Program

What’s the HAPS, Guys? Airbus and Williams Advanced Engineering, two heavy hitters with the world’s largest commercial airliner and the world’s fastest formula electric cars, are collaborating on making a light, slow airplane stay up indefinitely. Their memorandum of understanding (MOU) seeks to integrate Williams’ demonstrated abilities with “ultra-lightweight materials, battery technologies and electrical cell chemistries… in… Airbus’ Zephyr High Altitude Pseudo-Satellite (HAPS) program.” Airbus Defense and Space has worked with Sion Power Corporation since 2015 to use Sion’s proprietary lithium-Sulfur (Li-S) batteries for use in Airbus’ Zephyr aircraft. The current Zephyr S is the latest iteration of a series of solar-powered, unmanned aerial systems (UAS) that will fly at 65,000 feet for months at a time. High Over Dubai Airbus and Sion have expanded the Zephyr S’ performance envelope to accomplish a 336-hour flight in 2010, and a climb to 61,696 ft (18,805 meter) over the United Arab Emirates in 2014. Airbus compares the ability of Zephyr to that …

Silicon, Sulfur and 3D graphene Makes High-Performance Battery

Lithium-sulfur batteries display winning qualities, such as low production cost, environmental friendliness, and high energy density. Researchers usually give up, or look elsewhere, when the materials’ poor cycle life and loss of active materials on both anode and cathode show up. Researchers at Beihang University in Beijing report developing “a new Li-sulfur battery using honeycomb-like sulfur copolymer uniformly distributed onto 3D graphene (3D cpS-G) networks for a cathode material and a 3D lithiated Si-G network as anode.” They report “a high reversible capacity of 620 milli-Amp hours per gram, [and an] ultrahigh energy density of 1,147 Watt-hours per kilogram (based on the total mass of cathode and anode), good high-rate capability and excellent cycle performance over 500 cycles (0.028% capacity loss per cycle).” The materials used in the cathode and anode presented challenges. The “inherent insulation of sulfur” on the cathode and the high solubility of polysulfide intermediates cause an inability of the active materials to respond to one another, …

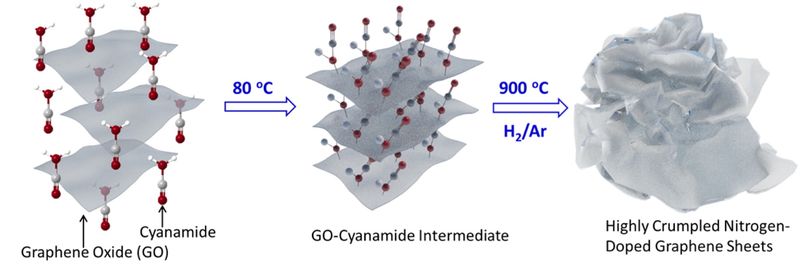

Rumpled Cathodes Benefit Lithium Sulfur Batteries

We like to think of things inside batteries as neatly organized, but Pennsylvania State University researchers may have come up with a less tidy way of making cathodes. Researchers synthesized “highly crumpled” nitrogen-doped graphene (NG) sheets with “ultrahigh pore volume” and large surface area (1,158 square meters– 12,465 square feet or about one-third the area of a football field) per gram. This large area and high porosity “enable strong polysulfide adsorption and high sulfur content for use as a cathode material in Li-sulfur batteries.” Interwoven rather than stacked, the wrinkled material provides ample room for “nitrogen-containing active sites.” The batteries, according to the researchers, “achieved” a high capacity of 1,226 milliamp-hours per gram and 75-percent capacity retention after 300 cycles. This demonstrated capacity and longevity is something other experimenters with lithium sulfur batteries have tried unsuccessfully to achieve. Green Car Reports quotes Jiangxuan Song, one of the researchers on the techniques used. “Lithium–sulfur battery cells using these wrinkled graphene sheets …

Lithium-Sulfur Cells Wrapped in Graphene

Graphene is science fiction made real – a one-atom thick layer of hexagonal arrays of carbon which weigh next to nothing and are stronger than any other material on earth. Wrap a layer of this stuff around “a novel multifunctional sulfur electrode that combines an energy storage unit and electron/ion transfer networks,” and you get “an extremely promising electrode structure design for rechargeable lithium-sulfur batteries.” Lithium-sulfur batteries have the promise of reaching a theoretical specific energy density “approaching 2,600 Watt-hours per kilogram (Wh kg-1),” compared to currently available specific energy densities for lithium-ion cells of 130-220 Wh kg-1. Researchers led by Dr. Vasant Kumar at the University of Cambridge and Professor Renjie Chen at the Beijing Institute of Technology worked to overcome the shortcomings of lithium-sulfur batteries now under development – a “fading” of the sulfur through a series of reactions with the anode, electrolyte, and lithium cathode, a kind of “shuttling” between these battery components, and the small number …

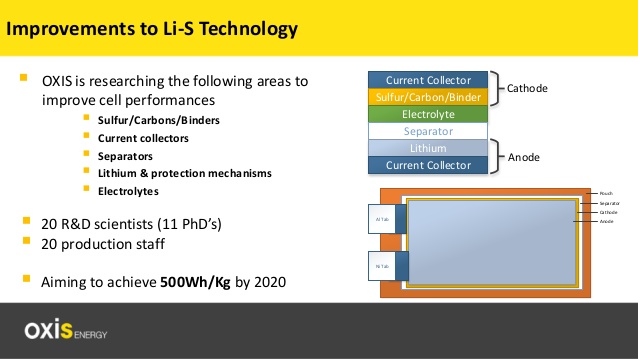

400 Watt-Hours per Kilogram by 2014

On its web site, the company boasts, “OXIS Energy is leading the World with its latest cell Energy Density and Capacity,” and proceeds to announce that it’s “developed its largest Lithium Sulfur cell achieving in excess of 300 [Watt-hours per kilogram]. This outperforms Lithium ion technology that has dominated the performance battery market for many years. In addition OXIS has achieved an increase in cell capacity to a 25 Amp-hour (Ah) cell – a world first.” They’re working toward a 33Ah cell. Claiming a twelve-fold improvement in the last 18 months, OXIS, a British battery manufacturer, says it has the confidence to “achieve a cell capacity of 33Ah by mid 2015.” The firm has hopes of energy densities “in excess of 400Wh/kg by the end of 2016 and in excess of 500Wh/kg by the end of 2018.” This doubling of energy density over the best of available lithium-ion batteries now would make the 175-mile-range Nissan Leaf a reality, and bring …

Lithium Sulfur Batteries – Energy Storage at New Heights

Last year, Oak Ridge National Laboratory (ORNL) announced that researchers had “successfully demonstrated that lithium-sulfur battery technology can indeed outdo lithium-ion on several fronts.” Theoretically, lithium-sulfur batteries could be four times as energy dense as today’s lithium-ion batteries, but that promise had yet to be demonstrated. ORNL took initial steps toward that goal, and within the last few months researchers at Vanderbilt University have shown a strong lead in forming lithium-sulfur batteries with commercial potential. Echoing work done at Sakti3, ORNL researchers demonstrated an all-solid-state lithium-sulfur cell, addressing flammability issues shared by batteries with solid electrolytes. Using lithium polysulfidophosphates (LPSPs) in the cathode, and which have ionic conductivities eight times higher than that of lithium sulfide (Li2S) the team coupled that with a lithium anode to create “an energy-dense, all solid battery.” Energy density was a noteworthy 1,200 mili-Amp-hours per gram, about 7 to 8.5 times that of conventional lithium batteries. A number of blogs repeated the slightly overheated lines …

Hybrid Batteries in Hybrid Vehicles?

Frances White of the Pacific Northwest National Laboratory (PNNL) reports that a new anode quadruples the life of a test lithium-sulfur battery and could lead to much lower costs for electric vehicles and large-scale energy storage. This blog has noted that many researchers focus on development of better cathodes, or anodes, or electrolytes exclusively, neglecting a more holistic, or whole battery approach to their delving. PNNL scientists have a reason for focusing on anodes, having found that a “battery with a dissolved cathode can still work.” What dissolves the electrodes in a battery? “Unwanted side reactions,” according to PNNL, cause the battery’s sulfur-containing cathode to disintegrate slowly and form polysulfide molecules that dissolve into the battery’s electrolyte liquid. This becomes a thin film that forms on the surface of the lithium-containing anode, and grows until the battery will no longer operate. Rather than trying to stop sulfur leakage from the cathode as others have, PNNL added a protective graphite shield …

- Page 1 of 2

- 1

- 2