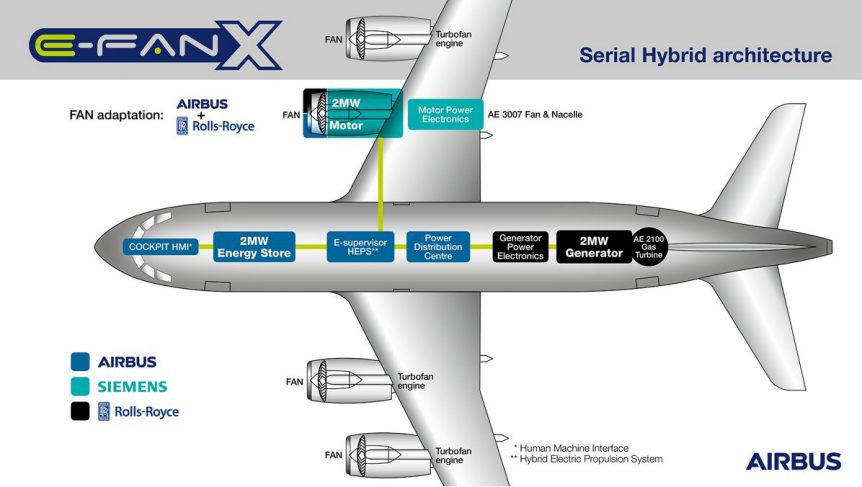

As many of your editor’s friends know, he is often lured to trolling the tabloids, looking for juicy bits about the royal family or Hollywood royalty. Recently, while perusing the Daily Mail* for news of the upcoming Harry/Meaghan nuptials, he came across the big-headline news that three European power players – Rolls-Royce, Airbus, and Siemens, are collaborating on creating a testbed for a hybrid power system. The trio will take a Bae 146 four-engine regional jet, convert it to a hybrid demonstrator by 2020, and have a production plane in place by 2030. The high-wing airplane has four turbofans in place now, but the partners will replace one with a Siemens two-megawatt electric motor powered by a Rolls-Royce two-megawatt generator in the plane’s cargo hold. The UK paper reports, ”The companies said they were looking ahead to the European Union’s long-term goals of reducing CO2 emissions from aviation by 60 percent, as well as meeting noise and pollution limits that …

Doing More with Less – BLI on a Big Scale

Hybrid and electric cars sell because they lower operating costs for the owner. Designers and manufacturers sort out ways to increase efficiency, including streamlining, using low-rolling-resistance tires, and making structures lighter. An added technology, boundary layer ingestion (BLI) may add to aircraft efficiency. NASA and industry leaders are working on equivalent solutions for aircraft, and airplanes will end up as different from today’s designs as Toyota Priuses and BMW i3s are from Ford Falcons or Chevrolet Corvettes. NASA proclaims, “An aviation renaissance, one focused on energy efficiency and economic impact, is on the horizon, and it’s changing how engineers look at aircraft power and design.” Jim Heidmann, a manager of NASA’s Advanced Air Transport Technology Project (AATT), says, “I feel we are at a tipping point in commercial aviation. We are exploring and developing game-changing technologies and concepts for aircraft and propulsion systems that can dramatically improve efficiency and reduce environmental impact and accelerate the introduction of new aircraft.” Think of …

109.5 minutes of Mad Creativity – Ending with an Electric Biplane

Peter Sripol is part of FliteTest, a group that sells electric model aircraft and components and produces some wild and wooly YouTube videos of their exploits. The group’s products are mostly budget items, with simple aircraft quickly constructed the norm. One example, the Simple Solar radio-controlled plane, can be built for under $60, and flies on two coreless motors. Flite Test has quick build kits and FPV (First Person View) radio systems that allow a pilot to view, through an on-board camera, what a (really tiny) person on board the model would see. This level of miniaturization and commodity-level pricing allows FliteTest to provide STEM (Science, Technology, Engineering and Math) kits to schools at the grade and high-school levels. MTV Meets Howard Hughes One of its newest members, Peter has jumped on FliteTest’s seeming willingness to try anything at least once. Putting together extremely large models from foam and tape, it probably was only natural that he would make a …

A123/Solid Power Partnership – A Safe Bet?

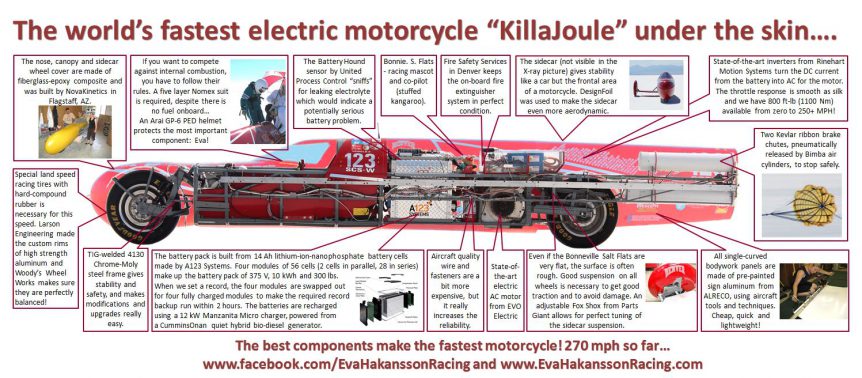

A123 Systems has worked with buffering chemistries to reduce the volatility of lithium batteries for the last decade. Solid Power Inc. has taken a set of interesting new technologies to make batteries more energy dense and safer. The two companies are combining efforts to make a more powerful, less-volatile battery, according to recent press releases. A123 produces nanophosphate (lithium iron phosphate – LiFePO4) and ultraphosphate batteries. Their nanophosphate batteries are used in Porsche’s 919 hybrid, a LeMans Prototype (LMP1) endurance racer that was outright winner of the event this year. They also power Eva Hakansson’s Killajoule and Bill Dube’s Killacycle – both record-holding electric motorcycles. Their Ultraphosphate line is designed to work at low voltages and low temperatures, including 48-Volt mild hybrid applications. Solid Power, a startup based on research done at University of Colorado Boulder, combines (“an exceptionally”) high-capacity cathode with a high-capacity lithium metal anode and a high ionic capacity solid separator. This combination produces, according to …

MGM Compro Enjoys Good News in Europe and at Oshkosh

MGM Compro is a Czech company that seems to have a motor on half of every light electric airplane flying today. Their motors have powered Airbus’s electric Cri-Cri (four 15-kilowatt units), the firm’s e-Fan, Ruppert Composite’s Archaeopteryx, e-Volo’s Volocopter, and any number of motorgliders and light sport aircraft buzzing quietly over Europe, and soon, America. Certification in Europe Certification is usually the route to wide acceptance of a new motor, proof that the unit has passed some rigorous tests and is suited for use in aircraft. As Martin Dvorsky, Managing Director for the firm reports: We are really proud to announce that [the] MGM COMPRO complex propulsion unit just obtained [a] CERTIFICATE OF AIRWORTHINESS issued by [the] Slovak Federation of Ultra Light Aircraft. This certificate means that the glider and its system has positively passed all the safety and flight tests and can be legally operated by LSZ license holder (UL license counterpart).” Note the clever motor and propeller folding and retraction …

eSpirit of St. Louis Runs at Oshkosh

One of the biggest thrills this year at Oshkosh was getting to see Eagle Flight Research Center’s DA-36 run its YASA electric motor. Eagle Flight, an outgrowth of Erik Lindbergh’s Powering Imagination program he’s been pursuing for the last several years, aims to create quiet electric aircraft that will carry sight-seers over National Parks and Monuments. Such flights would not disturb people or wildlife below, and would give a Gabriel’s eye view of the most pristine places in our country. International Approval His ideas have met with international support. As noted on the YouTube video of their meeting, “… Flavia Schlegel (Assistant Director-General (ADG) for the Natural Sciences) at UNESCO in Paris… gave an enthusiastic endorsement of our eSpirit of St. Louis electric aircraft development program!” Your editor became aware of the project when he spoke at the Powering Imagination Symposium at Seattle’s Museum of Flight in 2015. Erik told of his work with students at Embry Riddle Aeronautic University …

What We’re Looking Forward to at AirVenture 2017

We’re looking forward to seeing progress in electric aircraft, and this year may be an opportunity to see real breakthroughs. Two from Pipistrel Besides its regular lineup of high-quality aircraft, Pipistel will have two Alpha Electro trainers on display in their display area. This is the first time these aircraft will be seen in America, and they’ll be at the right of AirVenture’s main entrance gate in sites 86 and 87. In the Ultralight Area Mark Beierle will display and fly Bravo, Richard Steeves’ e-Gull. This red, white and blue gem features a power system made from Zero Motorcycle components and boasts an impressive rate of climb and exceptional short field capabilities. Another ultralight, the EMG-6 developed over the last few years by Brian Carpenter of Rainbow Aviation/Adventure Aircraft, will show off the REX 30 MGM-Compro motor from the Czech Republic. The units, with their matching controllers, power dozen of different types of aircraft in Europe, from paramotors to Light …

Two Multi-Rotors Half a World Apart

New Atlas (formerly Gizmag) alerted your editor to this web site, which in turn features over a score of YouTube videos on this fascinating project in Sweden. Axel Borg has created, as promised by the web site, an Amazing DIY Project, flying around a hilly woodland on the power of 76 electric motors. Undaunted by Fuel Fumes or Crashes More amazing, perhaps, he tried this configuration a year ago with eight internal combustion engines (extremely noisy), but managed to crash that. Resisting the fear that would instill in queasier souls (your editor, for instance), Axel made four tubular rings, within each of which is mounted a set of 19 motors. The four rings surround the pilot’s seat, under which are mounted four battery packs – each one supplying a set of motors with power. Axel has apparently done a good job of managing the control of the machine, showing in several videos his ability to maneuver in roll, pitch and …

ONERA’s AMPERE Flies on Distributed Electric Thrust

ONERA’s mission statement for its AMPERE (Avion à Motorisation réPartie Électrique de Recherche Expérimentale) electric aircraft is fairly straightforward. “AMPERE is a demonstrator of a regional airplane with electric propulsion distributed, allowing to transport from 4 to 6 people over 500 [kilometers – 310 miles] in 2 hours. The objective of the AMPERE project is to bring to maturity the technology of distributed electric propulsion in order to transfer it to the industry.” ONERA, the Office National d’Etudes et de Recherches Aérospatiales (National Office for the Study and Research of Aerospace) is the French equivalent of NASA. ONERA showed a one-fifth-scale model of AMPERE at the Paris Air Show last week, with spokesman and designer Jean Hermetz holding forth on the plane’s features. Pardon that the video is in French, but the images are universal. Note the wind tunnel tests at 1:45, showing attached flow over the wing segment on which the electric ducted fans are turning. The idea has …

EViation Electric Aircraft: Demanding Disruption

Aviation Week reports from the Paris Air Show on a “disruptive” entry in electric aviation. Eviation, founded by Omer Bar Yohai, is primed to deliver a change in transportation as we know it. Yohai says, “The dominant solutions available today are deeply flawed and demand disruption.” The company’s promotional video only hints at the company’s intentions. Their vision statement on their web site, though, indicates a skyward aspiration: “Making electric aviation the fast, competitive and clean answer to on-demand mobility of people and goods.” Aviation Week’s Noam Eshel quotes Bar Yohai as saying, “We design, test and build the tools that will enable future of regional transit by air, changing consumers’ perception of both distance and time. Five years from now, EViation is set to enable cheap, high-speed, sustainable and convenient regional commuting using light aircraft, tightly integrated with on-demand ground transport solutions. Currently, a sub-scale prototype is undergoing testing and risk-reduction evaluations. The company expects its first firm orders …